High pressure resistance sealed connector and adaptor thereof

A technology for adapter sockets and connectors, which is applied in the direction of connection, parts of connection devices, electrical components, etc., can solve the problems of being unable to withstand high pressure, and the sealing performance cannot meet the sealing requirements, so as to improve the pressure resistance and realize blindness. The effect of inserting and preventing misinsertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

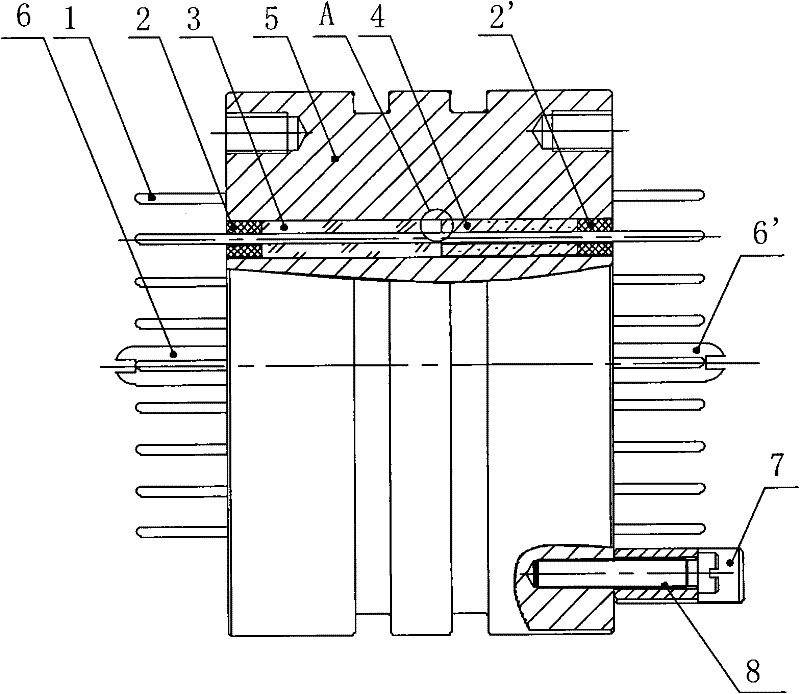

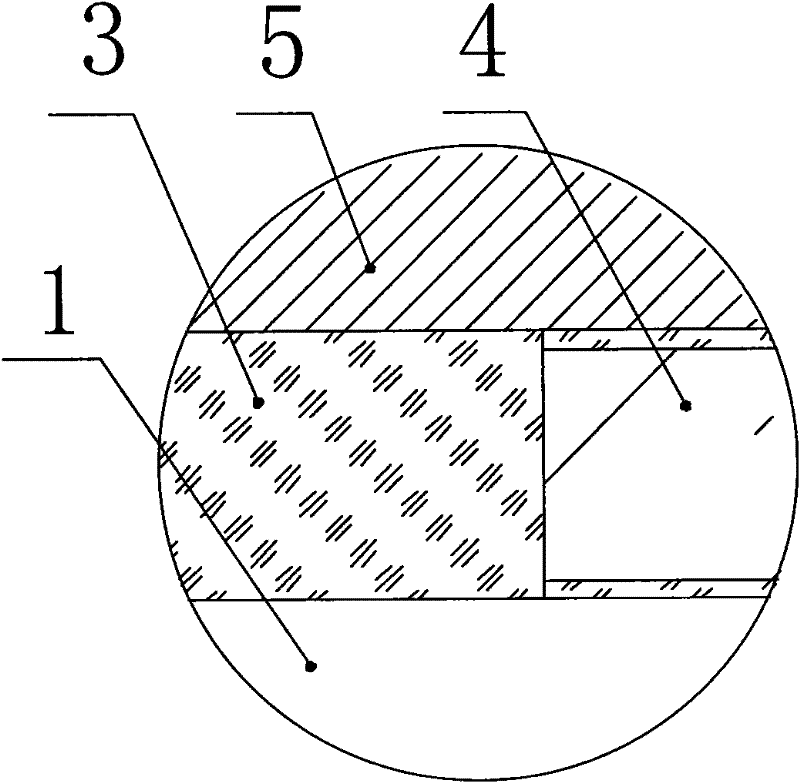

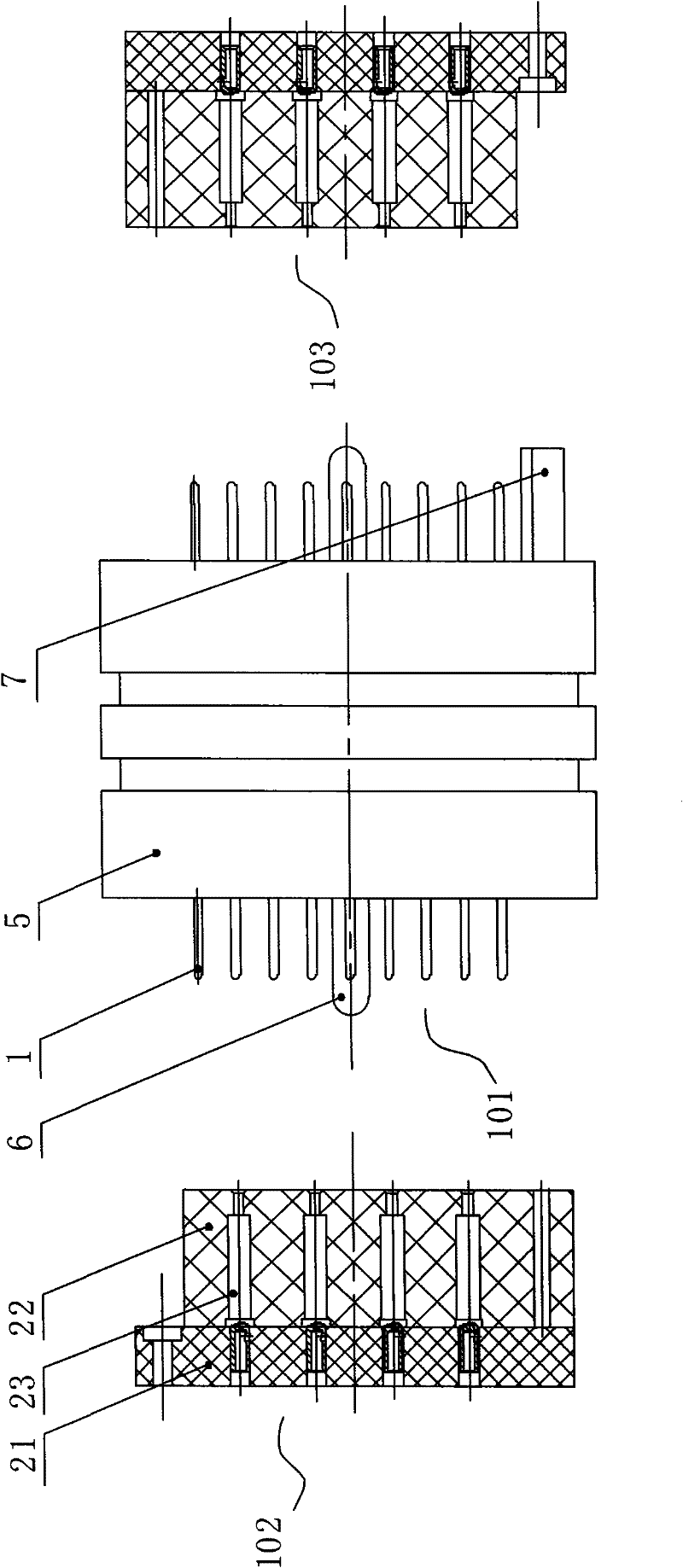

[0017] Such as figure 1 , figure 2 , image 3 As shown, the high-pressure resistant sealed connector of the present invention includes an adapter socket 101, and the adapter socket 101 includes a metal shell 5, and two channels are radially opened on the outer peripheral surface of the metal shell 5 for installing an O-shaped seal. ring seal ring groove. In the metal shell 5, there are several pin passages penetrating through its two end faces along the axial direction. Each pin passage is respectively equipped with a pin contact piece 1 along the axial direction, and the two ends of each pin contact piece 1 are respectively The end face of the metal shell protrudes from the axial extension. In the adapter socket 101, glass insulators 3 are provided between each pin contact piece 1 and the inner wall of the corresponding pin channel, and the outer circle of the pin contact piece 1 located in the pin channel and close to its one end port is sleeved with The ceramic insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com