Method for modeling variable section beam in micro-electronic-mechanical system (MEMS) level design

A variable cross-section beam and variable cross-section technology, applied in chemical instruments and methods, calculations, instruments, etc., can solve the problems that MEMS devices cannot be used for system-level simulation design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

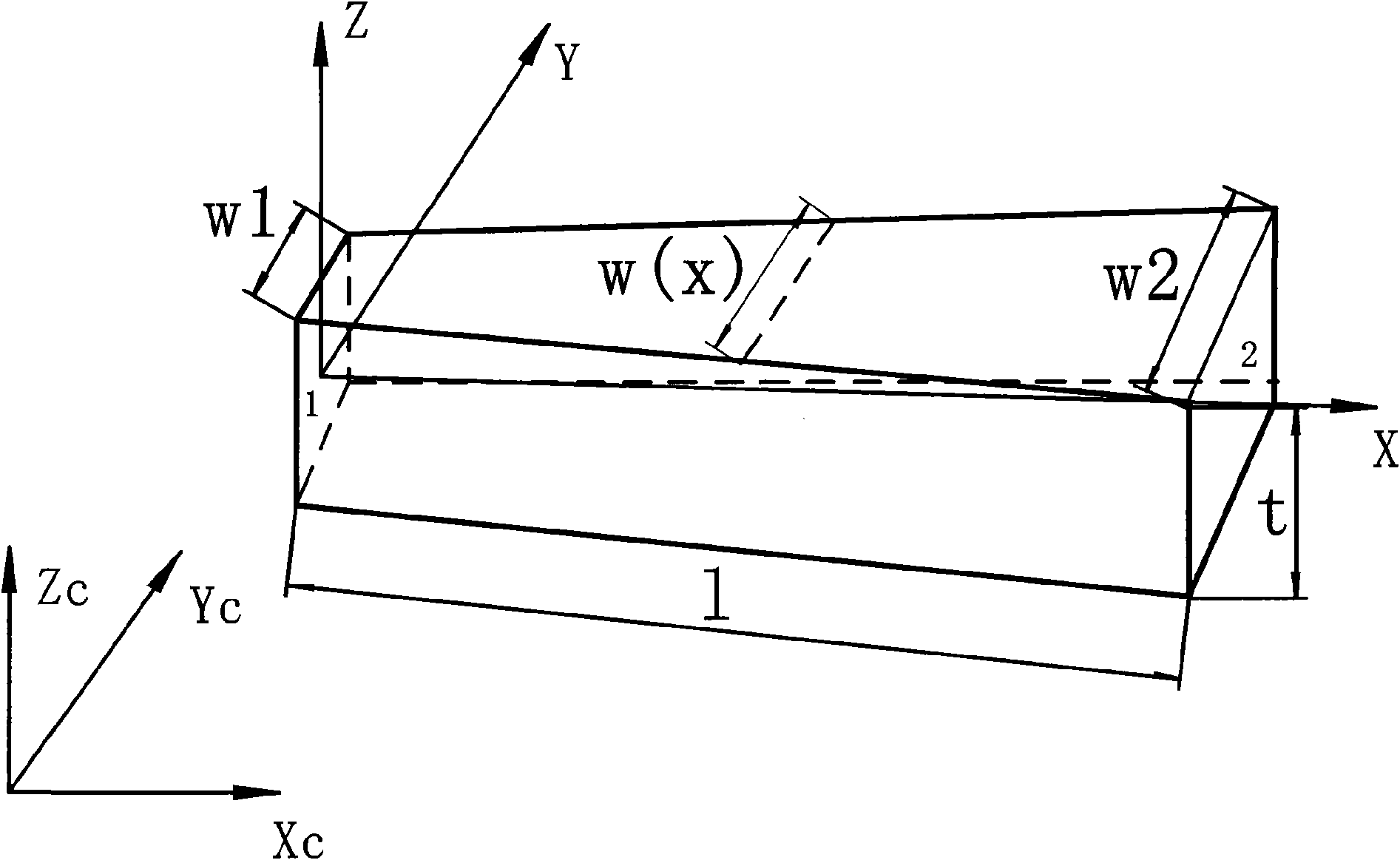

[0089] In the following, the present invention will be further described in combination with system-level component modeling of an actual variable-section beam structure. Known beam length l=200um, w1=30um, w2=5um, t=5um, E=130GP a , ρ=2330kg / m 3 , υ=0.22, B '=0; Initial azimuth α=0, β=0, γ=0; The concrete steps of the example of the present invention are as follows:

[0090] Step 1: Take the length direction of the variable cross-section beam as the x-axis, the width direction as the y-axis, and the thickness direction as the z-axis to establish a local coordinate system.

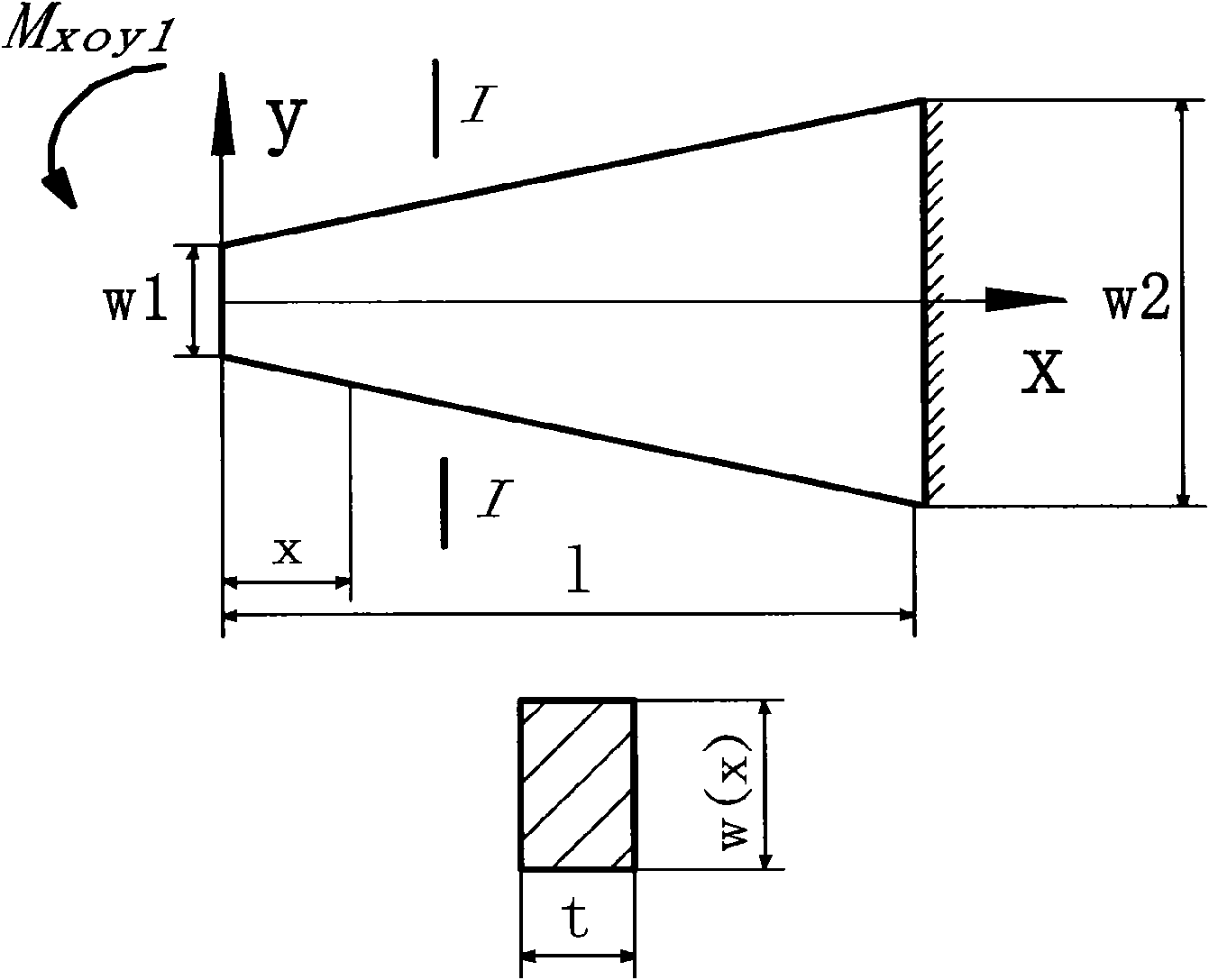

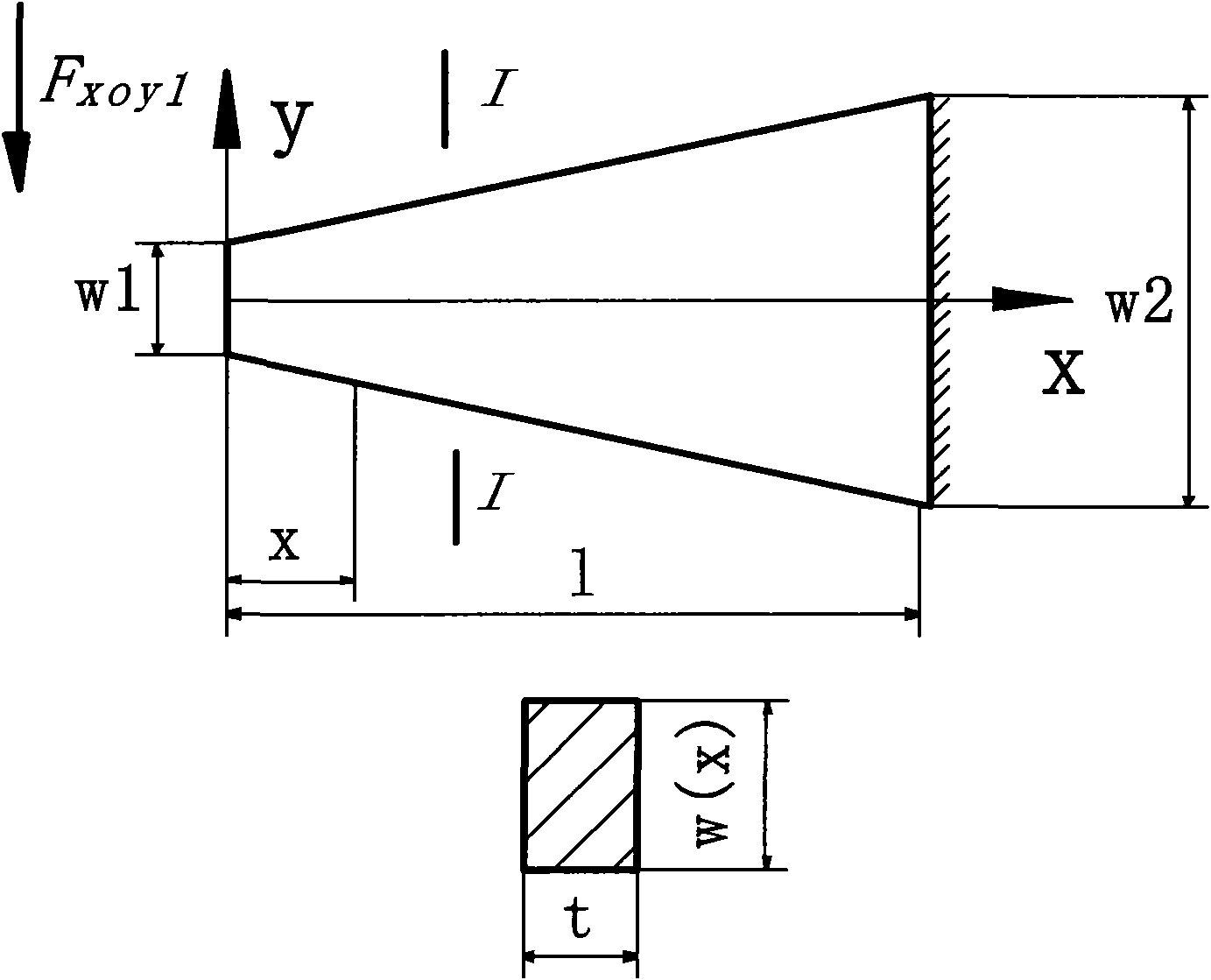

[0091] Step 2: Deduce the bending stiffness matrix [k of variable-section beams in the xoy plane yij ](i=1, 2, j=1, 2) and the bending stiffness matrix in the xoz plane [k zij ] (i=1, 2, j=1, 2).

[0092] The mechanical model of the cantilever beam is established by constraining the end face 2, and in the xoy plane, the formula (1)-(13) can be used to obtain

[0093] k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com