Preparation method of BBI

A technology of bisbenzenesulfonimide and benzenesulfonimide is applied in the field of preparation of electroplating nickel additives, which can solve the problems of affecting the quality of the coating layer and the electroplating efficiency, increasing the cost of Chinese enterprises, poor solubility, etc., and achieving cost reduction and reduction. The effect of pollution and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

[0018] raw material

[0019] Raw material code

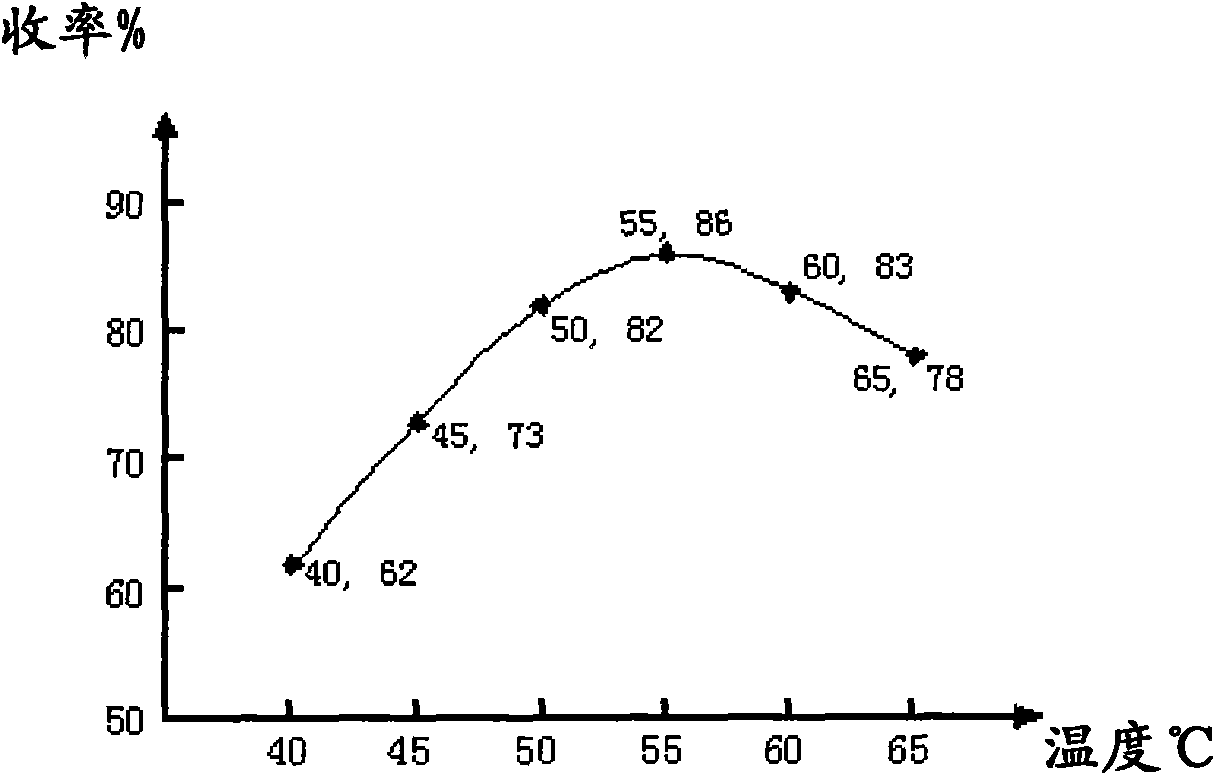

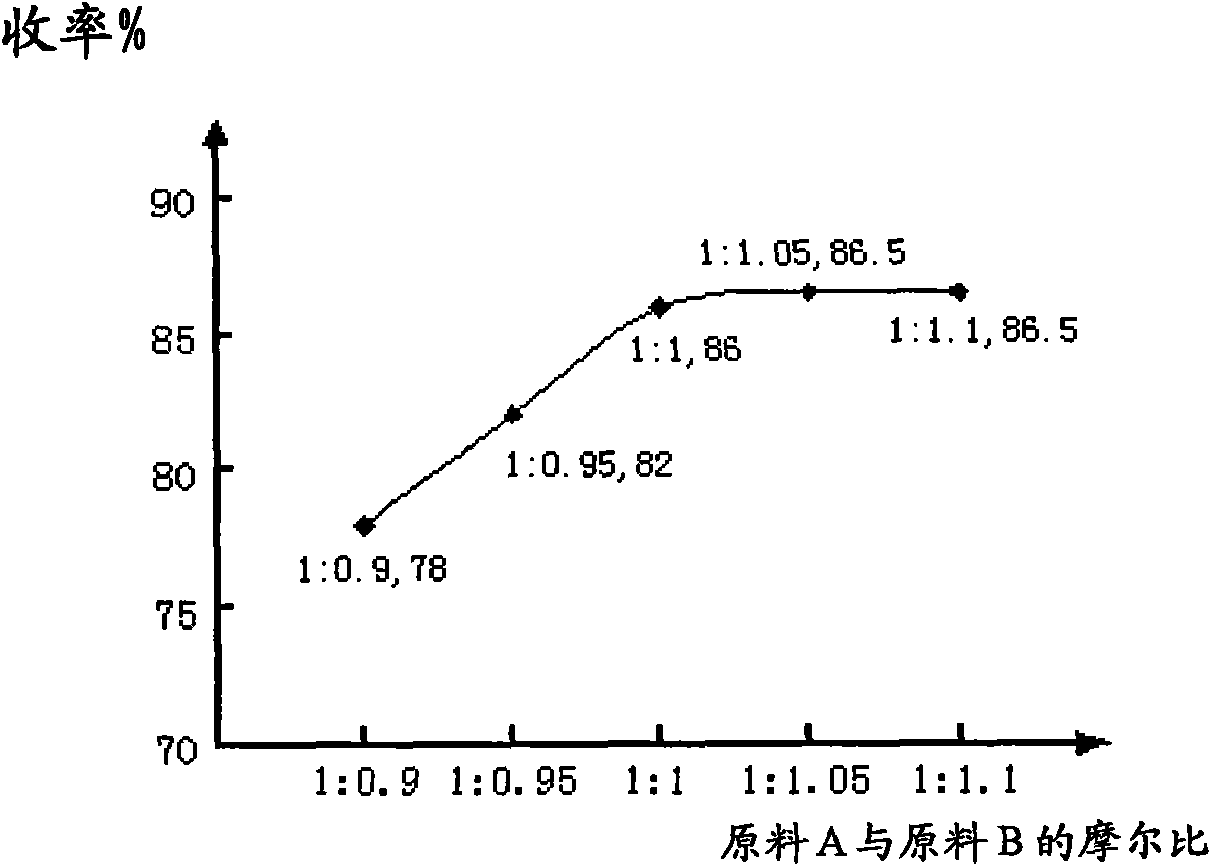

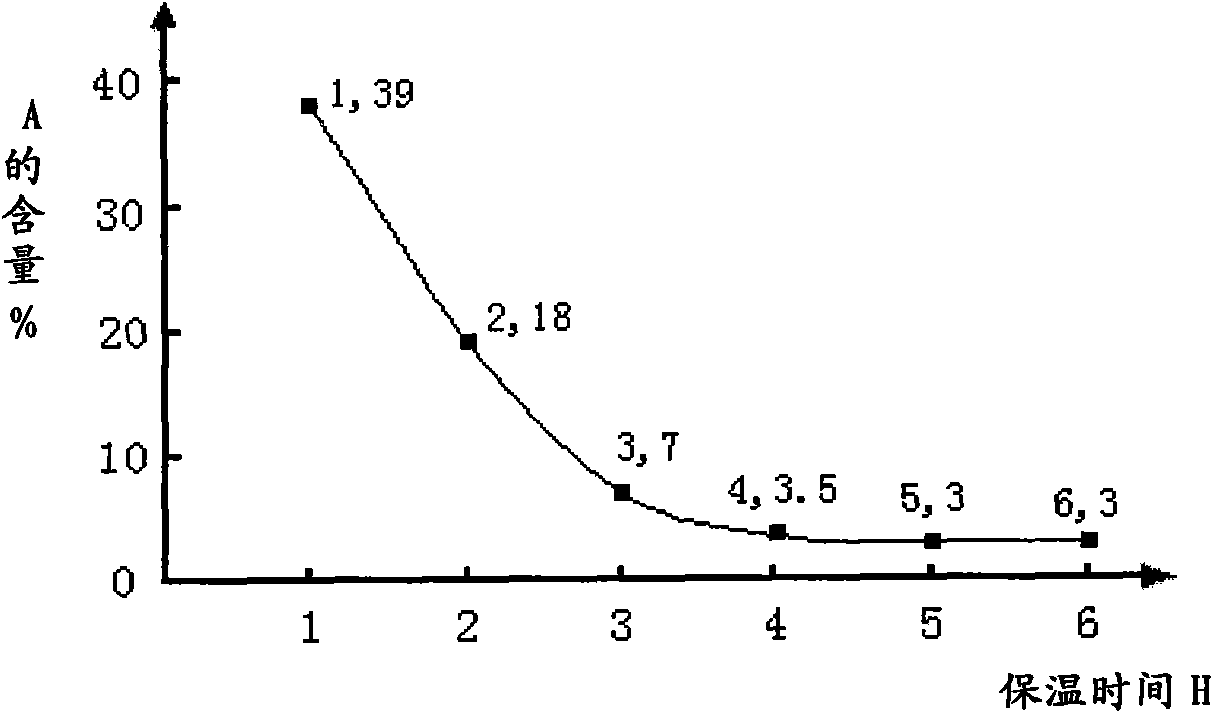

[0020] The preparation method of bis-benzenesulfonylimide of the present invention comprises the following steps: in a 2000ml reactor equipped with an electric stirrer, a thermometer, and a reflux condenser, 40 grams of sodium hydroxide and 800 grams of water are dropped into, and the sodium hydroxide is completely After dissolving, heat up to 50-57°C, add 150-165 grams of benzenesulfonamide, and control the temperature at 53-57°C. After the benzenesulfonamide is completely dissolved, start to add 170-180 grams of benzenesulfonyl chloride dropwise, and after 30 minutes , start to add sodium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com