Resourceful treatment method of paper-making sludge and system

A technology for papermaking sludge and treatment methods, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Problems such as secondary pollution of the burial site environment, to achieve the effect of solving land shortage, realizing resource recycling, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

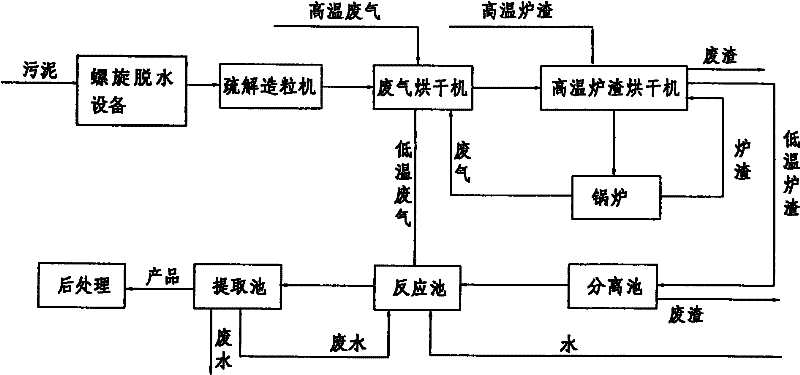

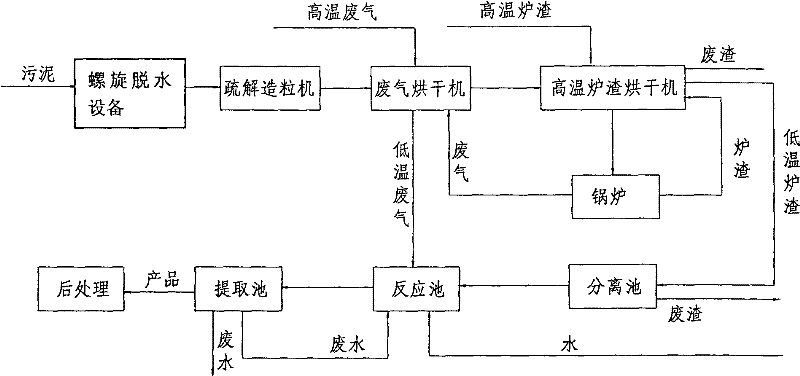

[0037] A kind of papermaking sludge treatment method of the present embodiment, such as figure 1 shown, including the following steps:

[0038] (1) Mechanically dewater the papermaking sludge first, and then disperse and granulate to form sludge particles; specifically:

[0039] (1-1) Send the papermaking sludge into the spiral dehydration equipment for mechanical dehydration to obtain the papermaking sludge with a dryness of 40% to 45%, and then send it into the granulator;

[0040] (1-2) The granulator breaks up the papermaking sludge and granulates it to obtain sludge particles that are convenient for further drying;

[0041] (2) Use high-temperature waste gas and high-temperature slag to dry the sludge particles twice, and then burn them; the high-temperature waste gas and high-temperature slag generated by the combustion of sludge particles are recycled, and the low-temperature waste gas generated by the double-dried sludge particles is fed into the In the reaction tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com