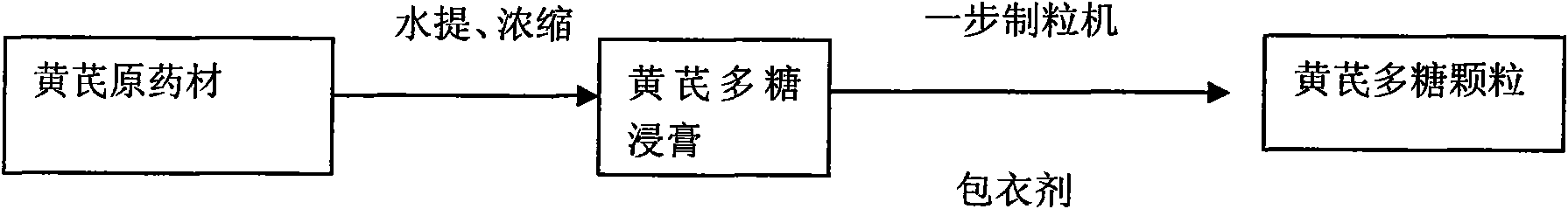

Method for producing astragalus polysaccharide particles

A technology of astragalus polysaccharide and production method, which is applied in animal feed, additional food elements, animal feed, etc., can solve the problems affecting the use and promotion of astragalus polysaccharide and the difficulty of mixing materials, and achieve the effect of protecting effective potency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Soak 100kg of Radix Astragali plus 6 times of water for 1 hour, heat to 100°C, extract twice for 1 hour, heat and concentrate to a relative density of 1.134-1.136. 30kg of the astragalus polysaccharide extract obtained, plus 55kg of starch and 15kg of dextrin, are placed in a one-step granulator for granulation and coating. The concentration of the coating agent acrylic resin solution is 5%. The process conditions are as follows: air intake: 4 gear, inlet air temperature 40-50°C, outlet air temperature 35-40°C, atomization pressure 1.5bar, nozzle diameter 1mm, spray speed 3-4ml / min.

Embodiment 2

[0015] Soak 100kg of Radix Astragali plus 6 times of water for 1 hour, heat to 100°C, extract twice for 1 hour, heat and concentrate to a relative density of 1.134-1.136. 30kg of the astragalus polysaccharide extract obtained, plus 60kg of starch and 10kg of dextrin, are placed in a one-step granulator for granulation and coating. The concentration of the coating agent acrylic resin solution is 5%. The process conditions are as follows: air intake: 4 gear, inlet air temperature 40-50°C, outlet air temperature 35-40°C, atomization pressure 1.5bar, nozzle diameter 1mm, spray speed 3-4ml / min.

Embodiment 3

[0017] Soak 100kg of Radix Astragali plus 6 times of water for 1 hour, heat to 100°C, extract twice for 1 hour, heat and concentrate to a relative density of 1.134-1.136. 28kg of the astragalus polysaccharide extract obtained, plus 52kg of starch and 20kg of dextrin, are placed in a one-step granulator for granulation and coating. The concentration of the coating agent acrylic resin solution is 6%. The process conditions are as follows: air intake: 4 gear, inlet air temperature 40-50°C, outlet air temperature 35-40°C, atomization pressure 1.5bar, nozzle diameter 1mm, spray speed 3-4ml / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com