Production method of low-sugar soya-bean milk

A production method and technology for soy milk, which are applied in milk substitutes, dairy products, applications, etc., can solve problems such as difficulty in producing low-sugar soy milk, and achieve the effects of reducing evaporation costs and avoiding pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A detailed description will be given below in conjunction with the accompanying drawings and embodiments.

[0019] The feed liquid used is soybean extract, and the water content is 94%-95%.

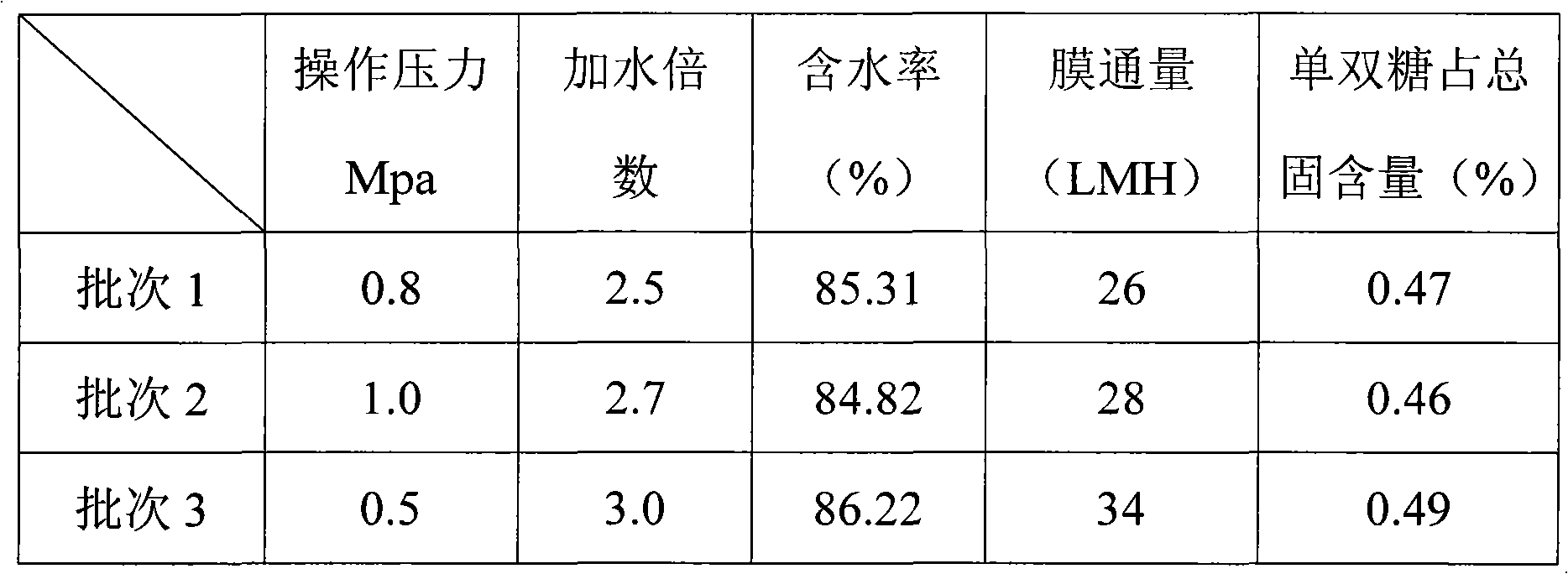

[0020] Pretreatment: Batch 1: Filtered with 50-mesh nylon filter bag, Batch 2: Filtered with 100-mesh nylon filter bag, Batch 3: Filtered with 200-mesh nylon filter bag;

[0021] Ultrafiltration sugar removal: the ultrafiltration membrane used in batch 1 and batch 2 has a molecular weight cut-off of 5,000 Daltons, and the ultrafiltration membrane used in batch 3 has a molecular weight cut-off of 10,000 Daltons;

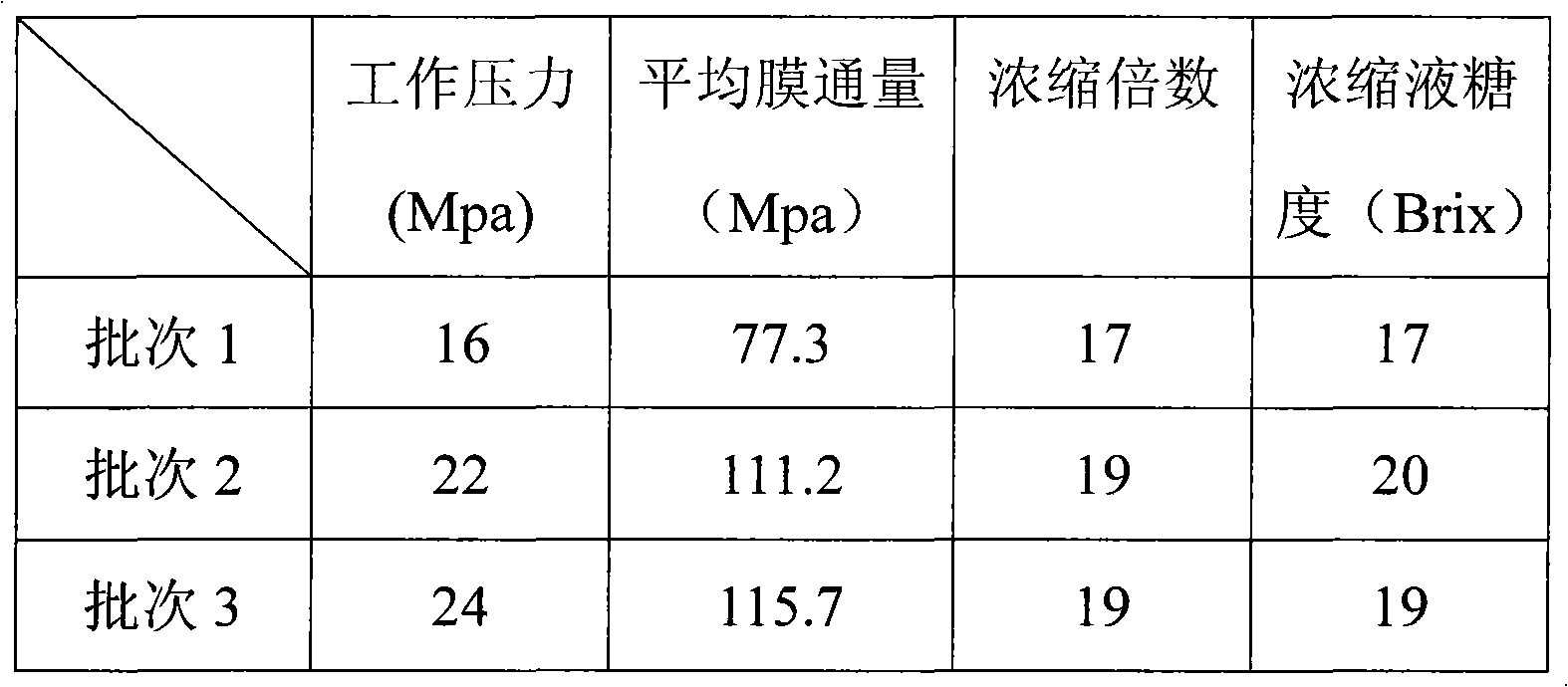

[0022] Nanofiltration concentration: The nanofiltration membrane used is a composite nanofiltration membrane with a molecular weight cut-off of 150-300 and a working pressure of 1.5-2.5Mpa.

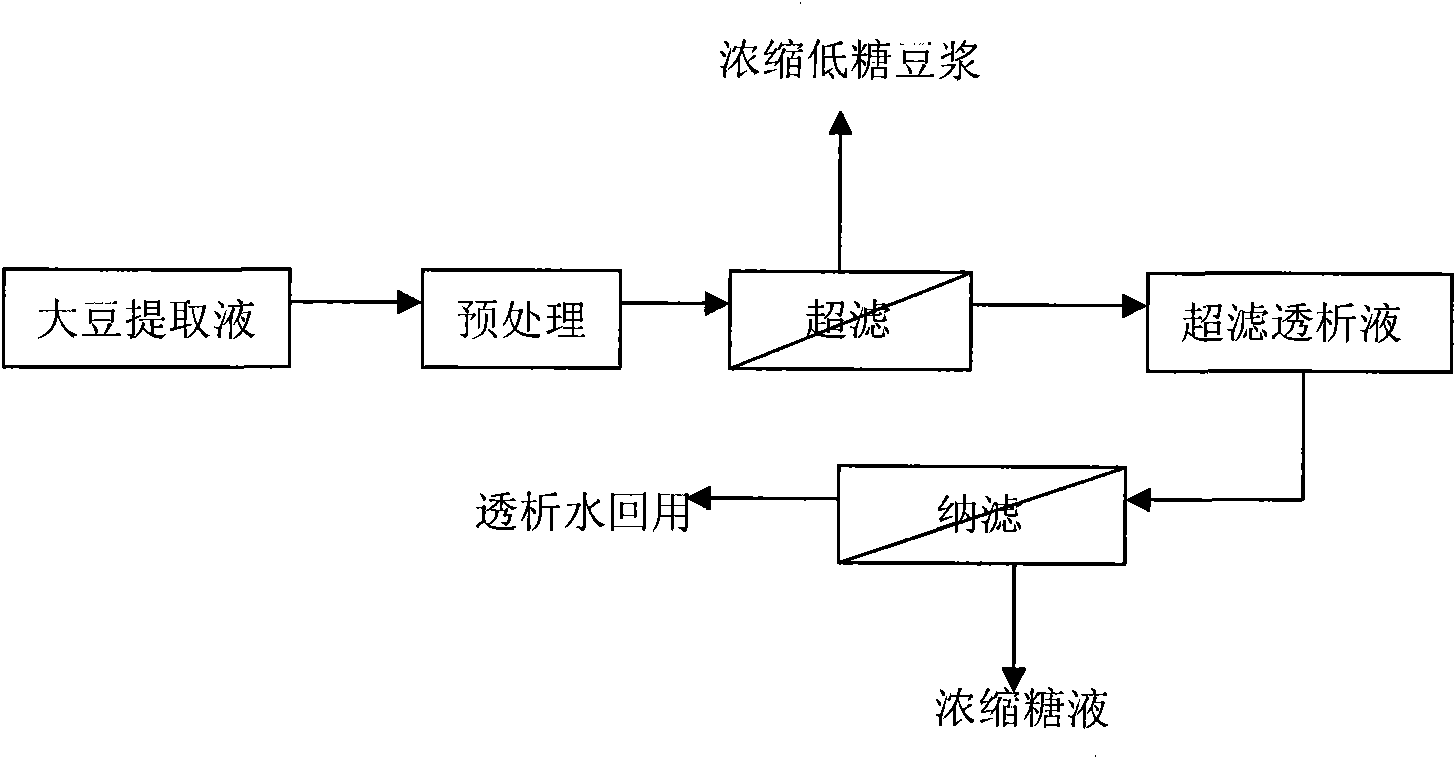

[0023] Such as figure 1 Implementation steps: 1. The soybean extract is first pretreated by a filter bag; 2. After the pretreated soybean extract liquid enters the ultrafiltration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com