Optimization control method specific to hazardous accidents of chemical risk source

A technology for optimizing control and optimizing methods, applied in instruments, gene models, alarms, etc., can solve problems that have not been seen in quantitative analysis and research, and achieve the effect of thorough decontamination, low price, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] According to the above technical solutions, the present invention will be described in detail below in conjunction with specific embodiments.

[0083] When a hazardous accident occurs, use a kind of hazardous accident control method for chemical risk sources of the present invention to control, and the specific operation steps are as follows:

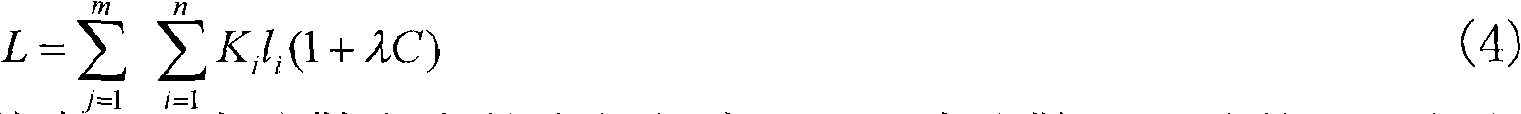

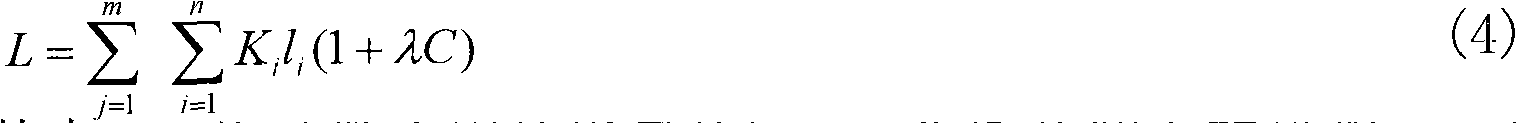

[0084] Step 1. Delineate the evacuation range and alert range

[0085] When the command center is alerted to the accident, it uses the GIS geographic information system and the chemical facility database to quickly predict the chemical hazards to determine the evolution of the chemical hazards in the future, and according to the chemical poison concentration (indicated by C) and toxicity (indicated by λ), Demarcate the lethal area, serious injury area, minor injury area and inhalation reaction area.

[0086] The specific classification standards are:

[0087] a. Lethal zone: If the people in this zone do not escape in time with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com