Clamp for detecting gas tightness of automobile cooling pipe

A car cooling and airtight technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the instability of hand strength, reduce production efficiency, clamping force Insufficient and other problems to achieve the effect of avoiding physical health, reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

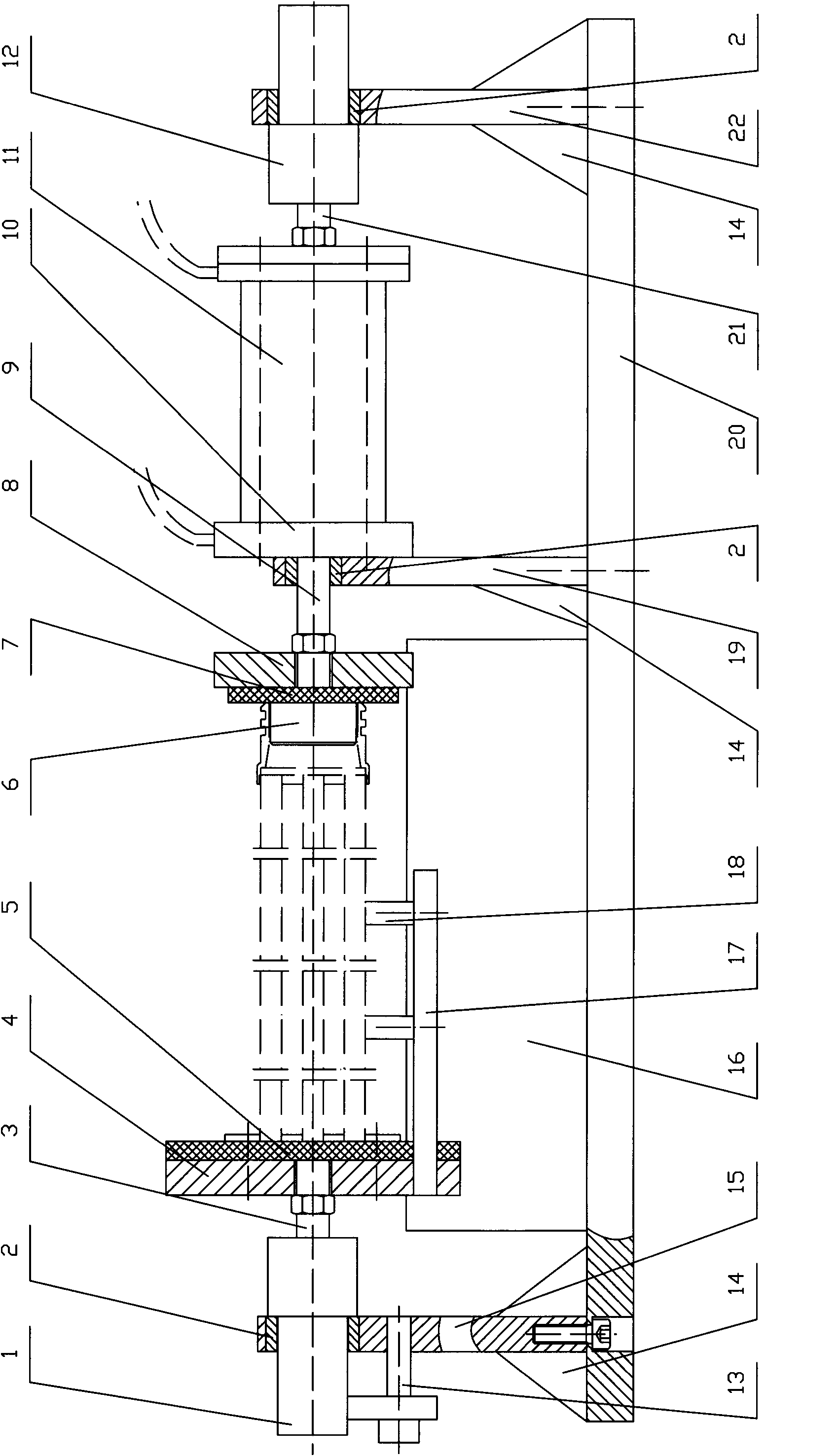

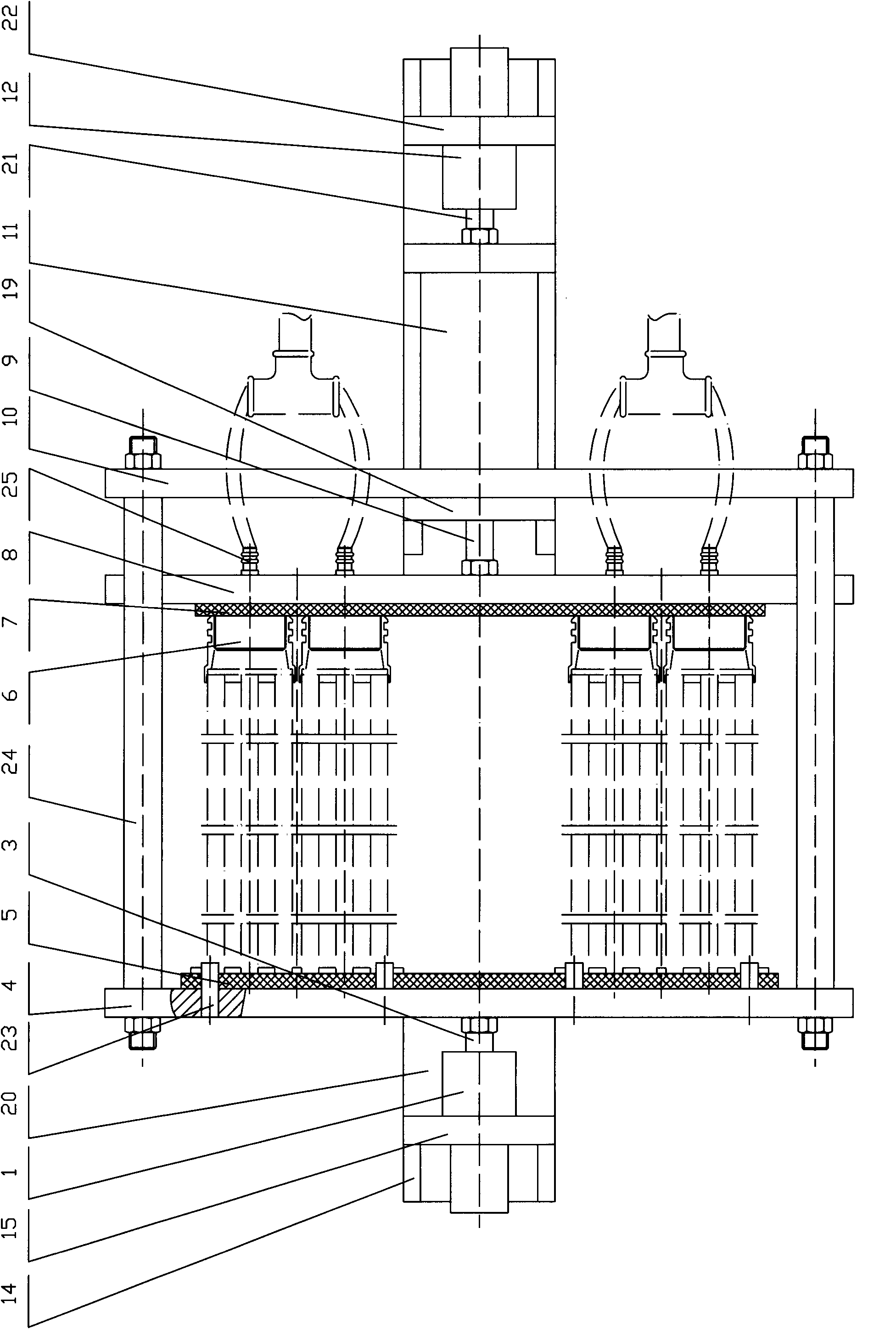

[0022] Depend on figure 1 , figure 2 It can be seen from the schematic structural diagram of the jig for testing the airtightness of automobile cooling pipes according to the present invention that it includes a ventilation device provided with an air nozzle 25, and the ventilation device is connected to an air source. It also includes a water tank 16, a left rotating shaft 1, a right rotating shaft 12, a supporting device and a clamping device, and the left and right rotating shafts 1, 12 are rotatably connected to the left and right ends of the supporting device respectively. One end of the clamping device is connected to the left rotating shaft 1 through the connecting shaft I 3 , and the other end is connected to the right rotating shaft 12 through the connecting shaft II 21 ; the air nozzle 25 is connected to the clamping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com