Negative pressure angle conical working tooth surface differential lock

A working tooth surface, negative pressure technology, applied in the direction of differential transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem of reducing vehicle passability, reducing wheel or axle adhesion, reducing driving force, etc. problem, to achieve the effect of improving off-road passing ability and good self-centering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The negative pressure angle conical working tooth surface differential lock of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

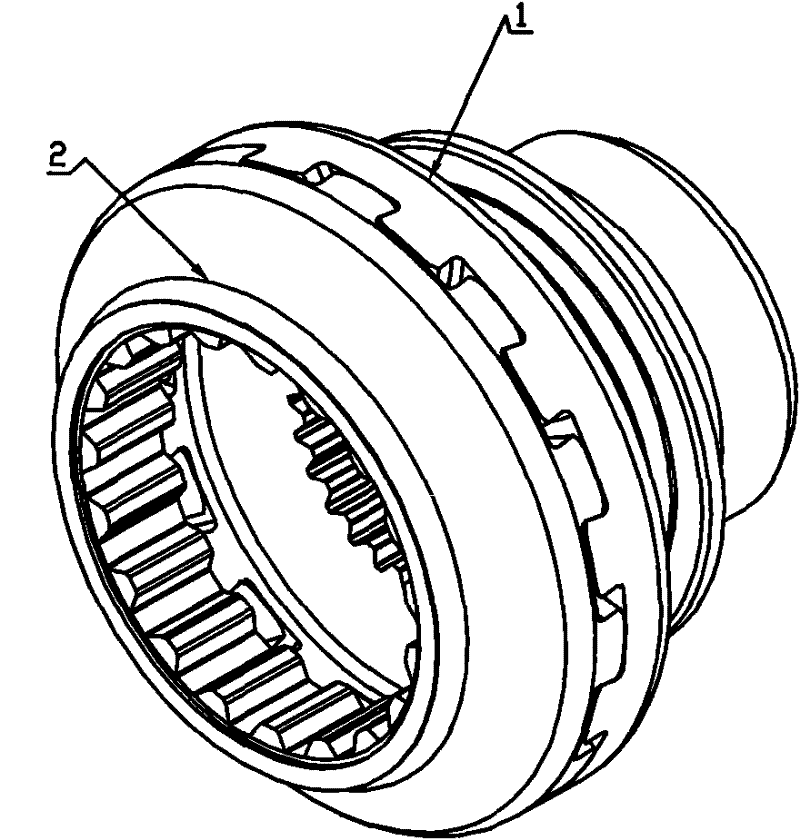

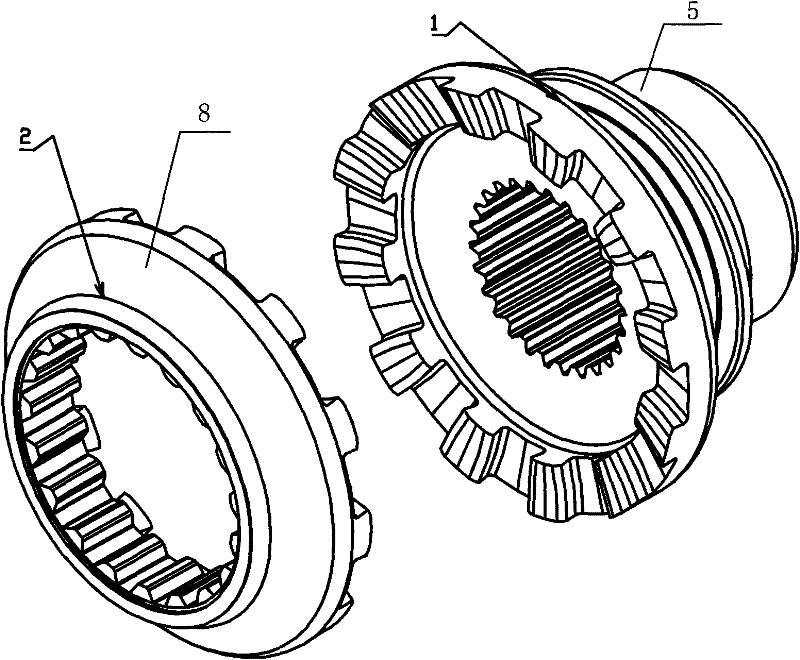

[0034] Such as figure 1 , figure 2 As shown, the negative pressure angle conical working tooth surface differential lock of the present invention includes: a sliding engagement sleeve 1 and a fixed engagement sleeve 2, and the sliding engagement sleeve 1 and the fixed engagement sleeve 2 are formed on the sliding engagement sleeve 1 The end face teeth 3 of the sliding engagement sleeve on the end face and the end face teeth 4 of the fixed engagement sleeve formed on the end face of the fixed engagement sleeve 2 engage with each other and are connected together.

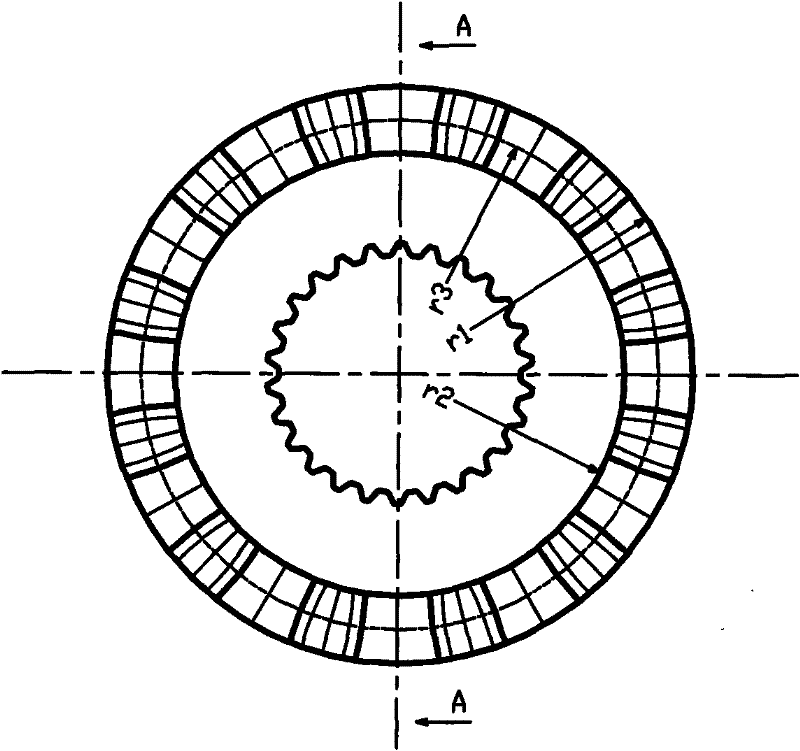

[0035] Such as image 3 , Figure 4 As shown, the sliding engagement sleeve 1 includes the end face teeth 3 of the sliding engagement sleeve and the sliding engagement sleeve body 5 integrally formed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com