Axial-flow type pneumatic dedusting fan

A dedusting fan, axial flow technology, applied in axial flow pumps, machines/engines, liquid fuel engines, etc., can solve the problems of electric dedusting fan burning motor, insufficient equipment pressure, too much space for equipment, etc., to achieve great practicality and Promotional value, low cost, and the effect of improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

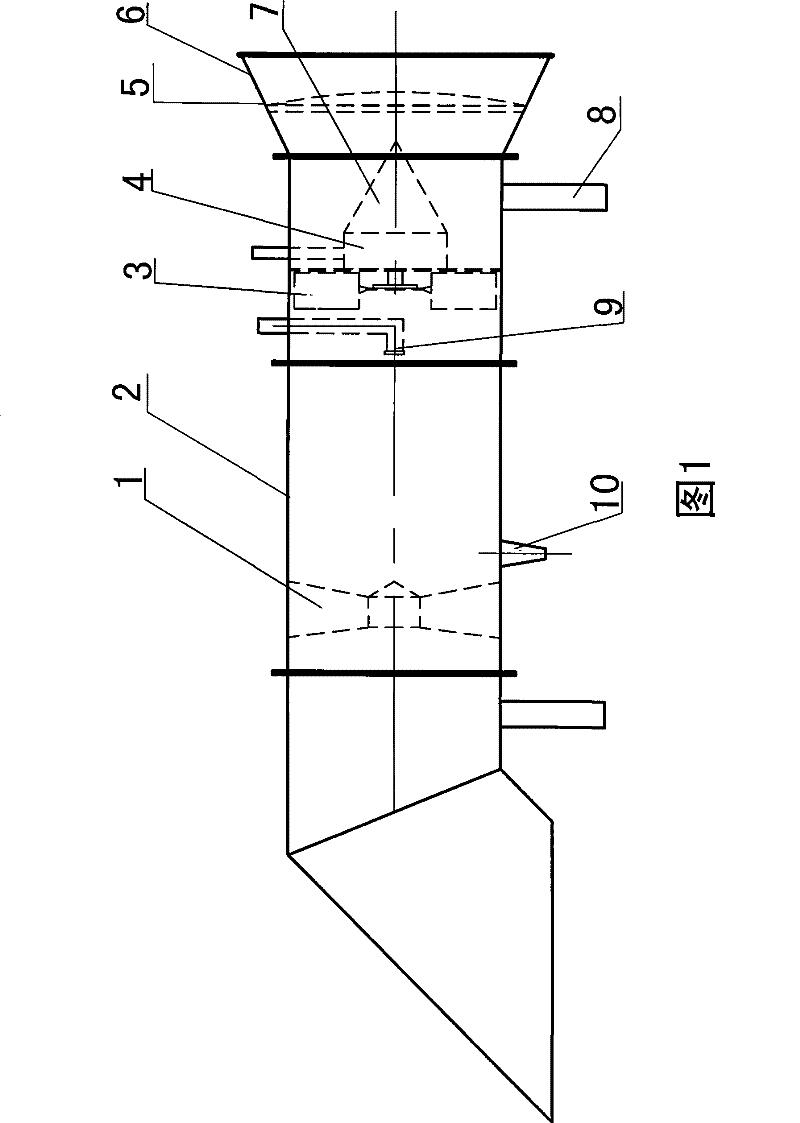

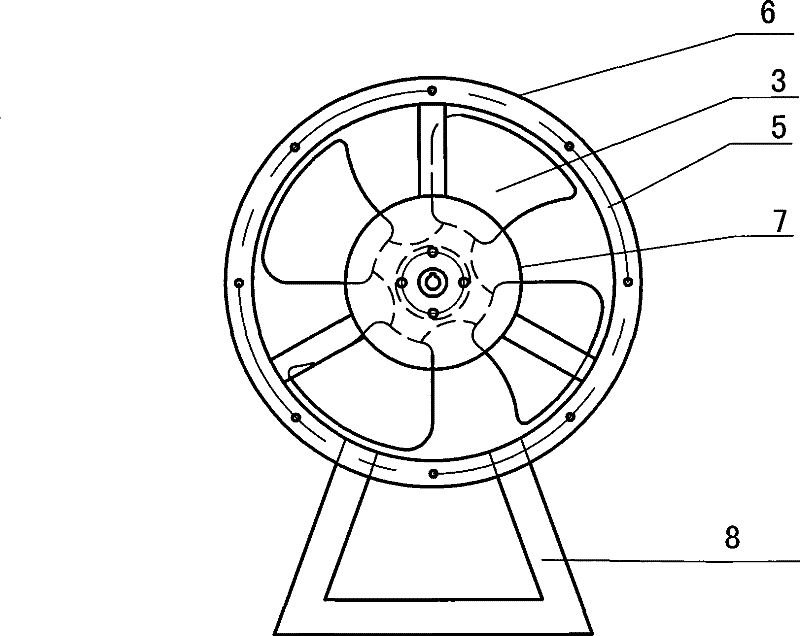

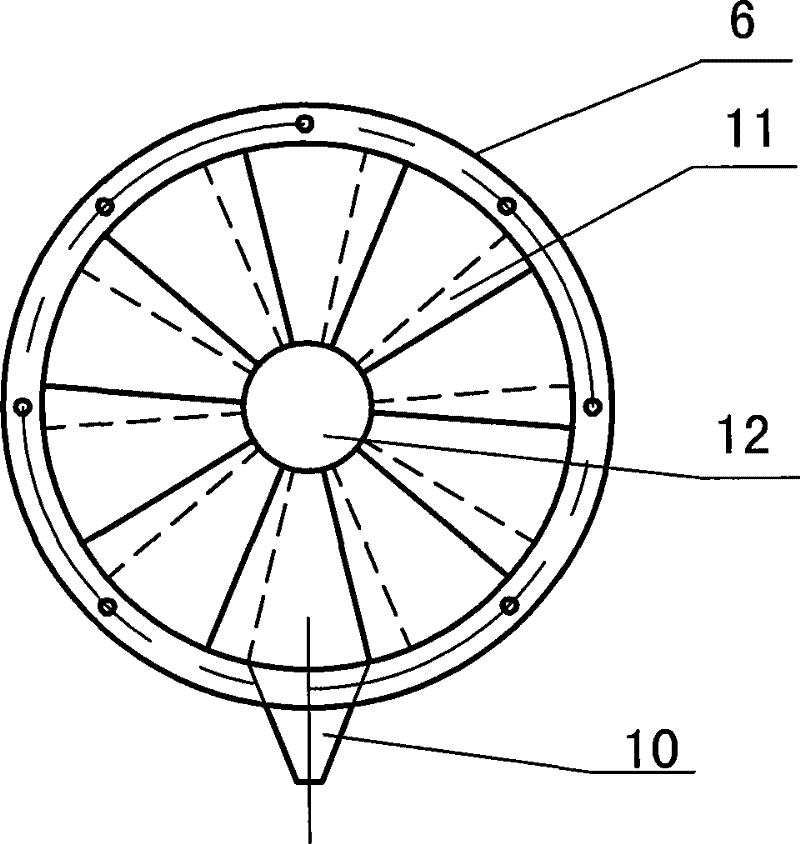

[0019] Attached below Figure 1-3 The axial flow type pneumatic dedusting fan of the present invention is described further:

[0020] refer to Figure 1-3 :

[0021] The axial-flow wind-driven dedusting fan of the present invention consists of a swirl tuyere 1, an air guide tube 2, an impeller 3, a blade-type wind motor 4, a filter screen 5, a current collector 6, a dredging cover 7, a high-speed nozzle 9, Liquid guide port, deflector 11, throat 12 are formed. The collector 6 is installed at the front end, and the throat shape and diameter of the collector 6 have a great influence on the efficiency of the fan. The shape and size of the gap between the collector 6 and the inlet of the impeller 3 has an important influence on the volume loss and flow loss. Through the test, the collector 6 is designed and made into a trumpet shape. After the airflow enters the collector 6, it accelerates slowly Finally, evenly fill the entire impeller with 3 blades. A screen cloth 5 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com