Construction waste sintering brick and production method thereof

A technology for construction waste and sintered bricks, applied in construction, building components, building structures, etc., can solve the problems of inability to achieve industrialization, easy peeling of sintered bricks, difficult sintering, etc. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

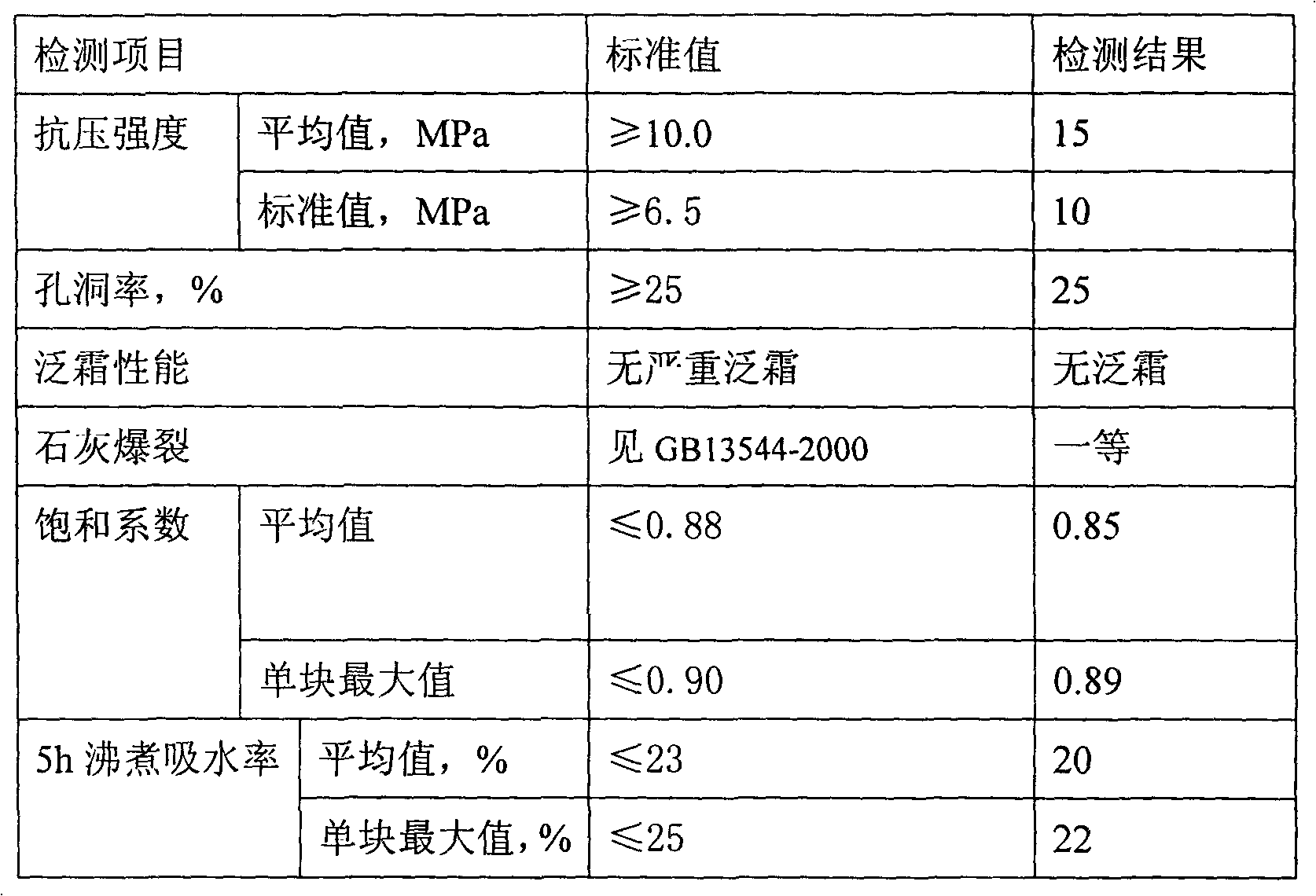

Embodiment 1

[0044] Raw materials include the following components and weight percentages:

[0045] River silt with a moisture content of 20% 25%

[0046] Construction waste powder after removal of impurities and aging treatment (powder particle size 1-3mm) 35%

[0047] Fly Ash 17%

[0048]Coal gangue (powder particle size 1-3mm) 11%

[0049] Adhesive ("Wall" brand inferior clay reinforcement) 3%

[0050] Kiln dust 9%

[0051] Obtaining construction waste powder after removal of impurities and aging treatment:

[0052] Crush the construction waste to a particle size of 0.5-2cm, remove iron with a magnet, then grind the construction waste after iron removal, and screen out powder with a particle size of 1-3mm. Adding water to pile up the construction waste powder from which impurities have been removed, controlling the moisture content to 16±3%, and obtaining it after aging for 7 days.

[0053] Preparation method of construction waste sintered bricks:

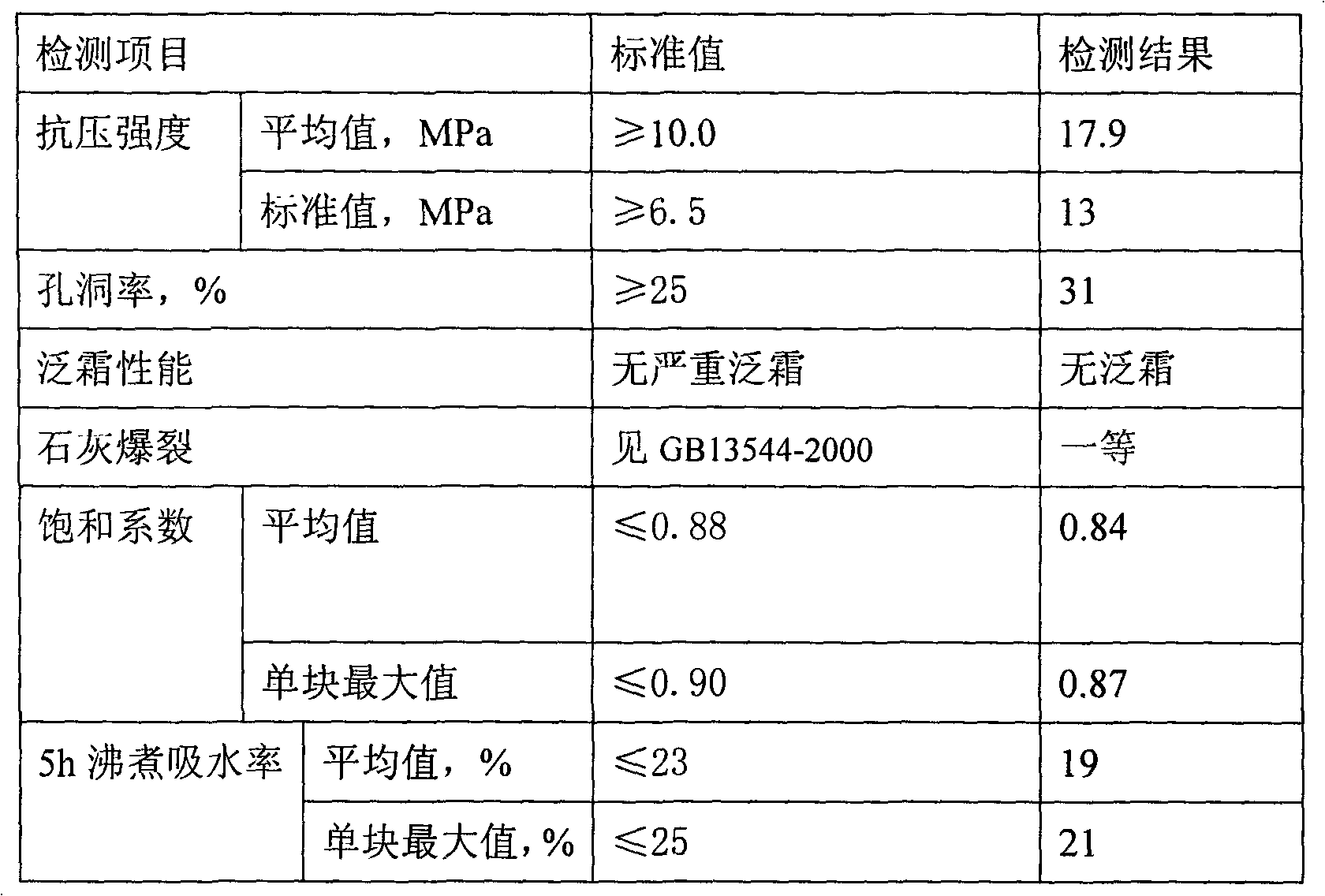

Embodiment 2

[0059] Raw materials include the following components and weight percentages:

[0060] River silt with a moisture content of 14% 27%

[0061] Construction waste powder after removal of impurities and aging treatment (powder particle size 1-3mm) 39%

[0062] Fly Ash 16%

[0063] Coal gangue (powder particle size 1-3mm) 15%

[0064] Binder 2.5%

[0065] Kiln dust 0.5%

[0066] Obtaining construction waste powder after removal of impurities and aging treatment:

[0067] Crush the construction waste to a particle size of 0.5-2cm, remove the iron with a magnet, then crush, grind and roll the construction waste after iron removal, and screen out the powder with a particle size of 1-3mm. Pile the construction waste powder with impurities removed, control the water content to 16±3%, and obtain it after aging for 14 days.

[0068] Preparation method of construction waste sintered bricks:

[0069] 3) Mixing fly ash, coal gangue, impurity-removed and aged construction waste, river...

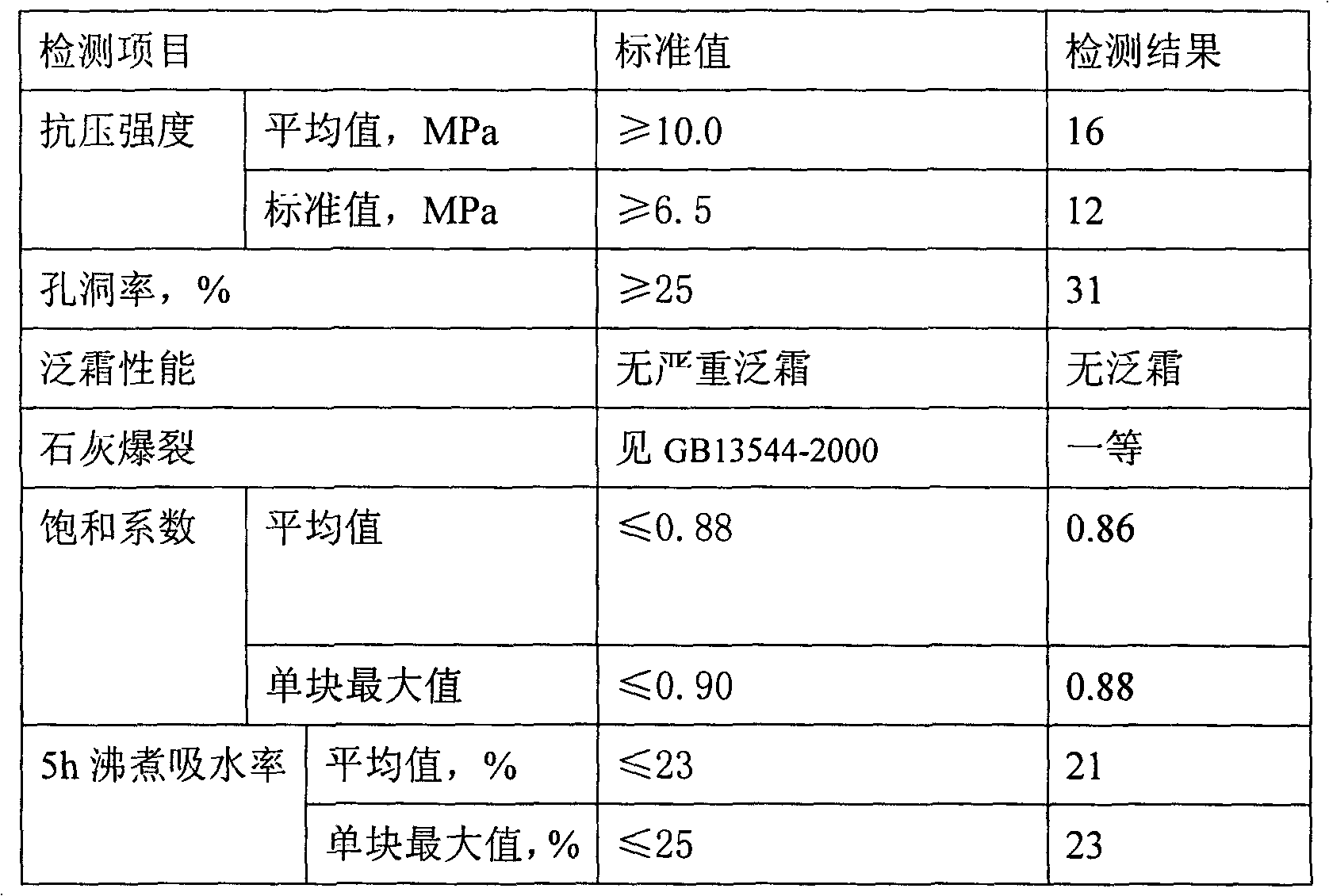

Embodiment 3

[0075] Raw materials include the following components and weight percentages:

[0076] River silt with a moisture content of 18% 24%

[0077] Construction waste powder after removal of impurities and aging treatment (powder particle size 1-3mm) 37%

[0078] Coal gangue (powder particle size 1-3mm) 33%

[0079] Binder 1.5%

[0080] Silt dry powder 4.5%

[0081] Obtaining construction waste powder after removal of impurities and aging treatment:

[0082] Crush the construction waste to a particle size of 0.5-2cm, remove iron with a magnet, then grind the construction waste after iron removal, and screen out powder with a particle size of 1-3mm. The construction waste powder from which impurities have been removed is piled up with water, the water content is controlled to be 16±3%, and it is obtained after aging for 10 days.

[0083] Preparation method of construction waste sintered bricks:

[0084] 5) According to the aforementioned ratio, coal gangue is mixed with constru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com