Prefabricated part composite cement soil wall and construction method thereof

A prefabricated component and composite cement technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as troublesome steel removal, poor stress characteristics, waste of steel consumption, etc., to save the cost of mechanical research and development, improve the surrounding The form of protective structure and the effect of meeting the needs of engineering construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

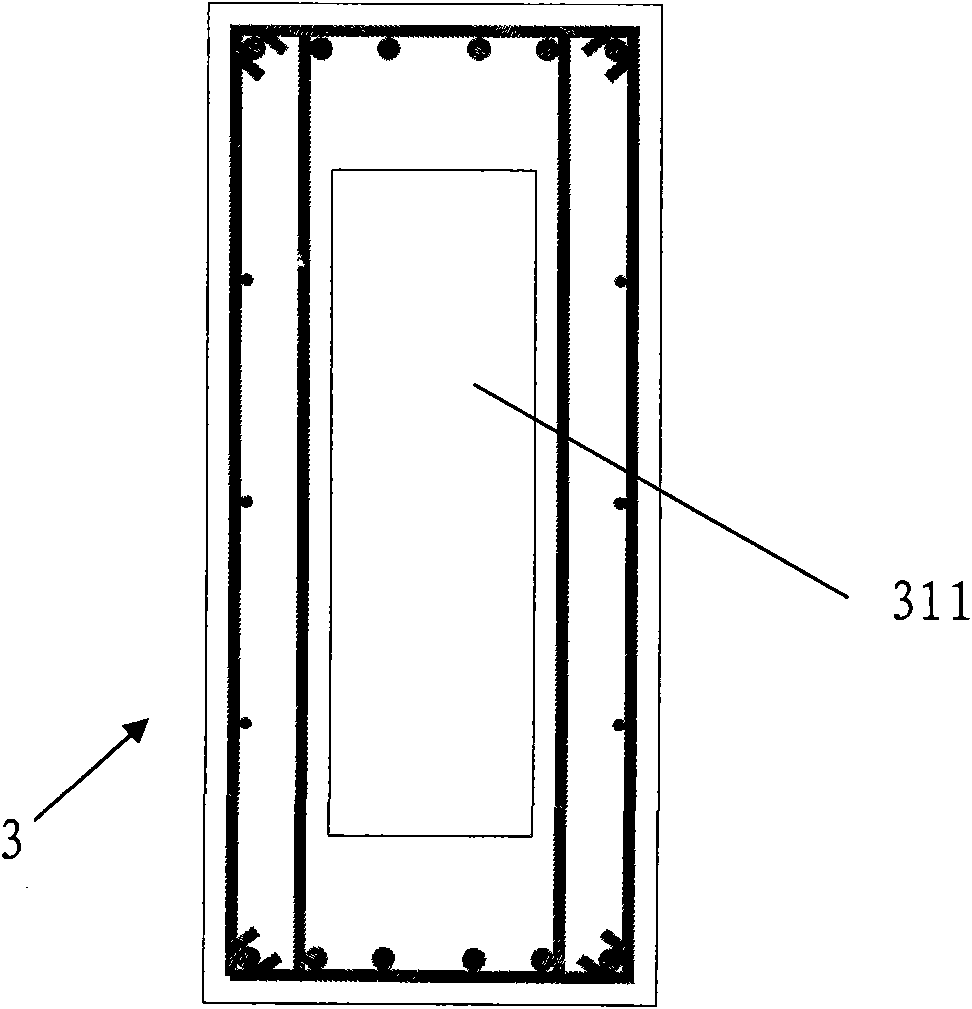

[0056] see Figure 1a , Figure 1b , this kind of prefabricated component composite cement-soil wall includes several cement-soil piles 1 containing cement-soil, adjacent cement-soil piles 1 are interlocked, and each cement-soil pile 1 is inserted with a long prefabricated Build 3. The cement-soil piles 1 are constructed using a three-axis cement-soil mixing pile construction machine, and every three cement-soil piles 1 are constructed simultaneously. Every three cement-soil piles 1 form a pile unit group, and each pile unit group 1 includes a head pile, a middle pile and a tail pile in turn, and adjacent piles are interlocked. During construction, first divide all cement-soil piles into several pile unit groups. All pile unit groups are divided into first order pile unit groups and second order pile unit groups. The first sequential pile unit group and the second sequential pile unit group are arranged at intervals from each other. The first pile of the second sequence pi...

Embodiment 2

[0061] The difference between this embodiment and embodiment 1 is that the prefabricated component 3 is a steel-concrete composite beam component, that is, a steel-concrete composite structure. Compared with the steel structure, this steel-concrete composite structure saves steel, enhances the rigidity of components or buildings, and improves the deformation resistance. Compared with ordinary reinforced concrete structures, this steel-concrete composite structure reduces the weight, increases the ductility of components, and has higher strength, which can give full play to the material properties of steel and concrete. , so that the unity of technology and economy can be achieved.

[0062] see figure 2 , the specific structure of the steel and concrete composite beam member is as follows: it includes an H-shaped steel 321 and two reinforced concrete slabs 322 . The reinforced concrete slab 322 consists of a concrete slab provided with several steel bars. The H-shaped steel...

Embodiment 3

[0065] see Figure 3a and Figure 3b , The difference between this embodiment and Embodiment 1 is that: the prefabricated component 3 is a steel and concrete composite truss component. The steel and concrete composite truss member includes a reinforced concrete slab 332 and a steel truss 321 . The steel truss 321 is composed of upper and lower chords 3211, 3212 connected by several webs 3213. The reinforced concrete slab 332 is fixedly connected to the upper side of the upper chord 3211 of the steel truss 321 . The reinforced concrete slab 332 is connected to the upper chord 3211 of the steel truss 321 by bolts. The upper and lower chords 3211 and 3212 of the steel truss 321 can be made of angle steel, and the web 3213 can be made of steel pipes.

[0066] This steel and concrete composite truss beam member is a new type of composite structure, which has good mechanical properties and good economy, and can be widely used in long-span, heavy-load high-rise buildings and supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com