Nutrient conditioner for acidified soil in orchards, and preparation method

A soil conditioner and nutritional technology, which is applied in the field of nutritional soil improvement, can solve the problems of insufficient soil pH value reduction, no strong pertinence, no positive reports, etc., so as to improve fruit yield and improve The effect of soil physical and chemical properties and nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

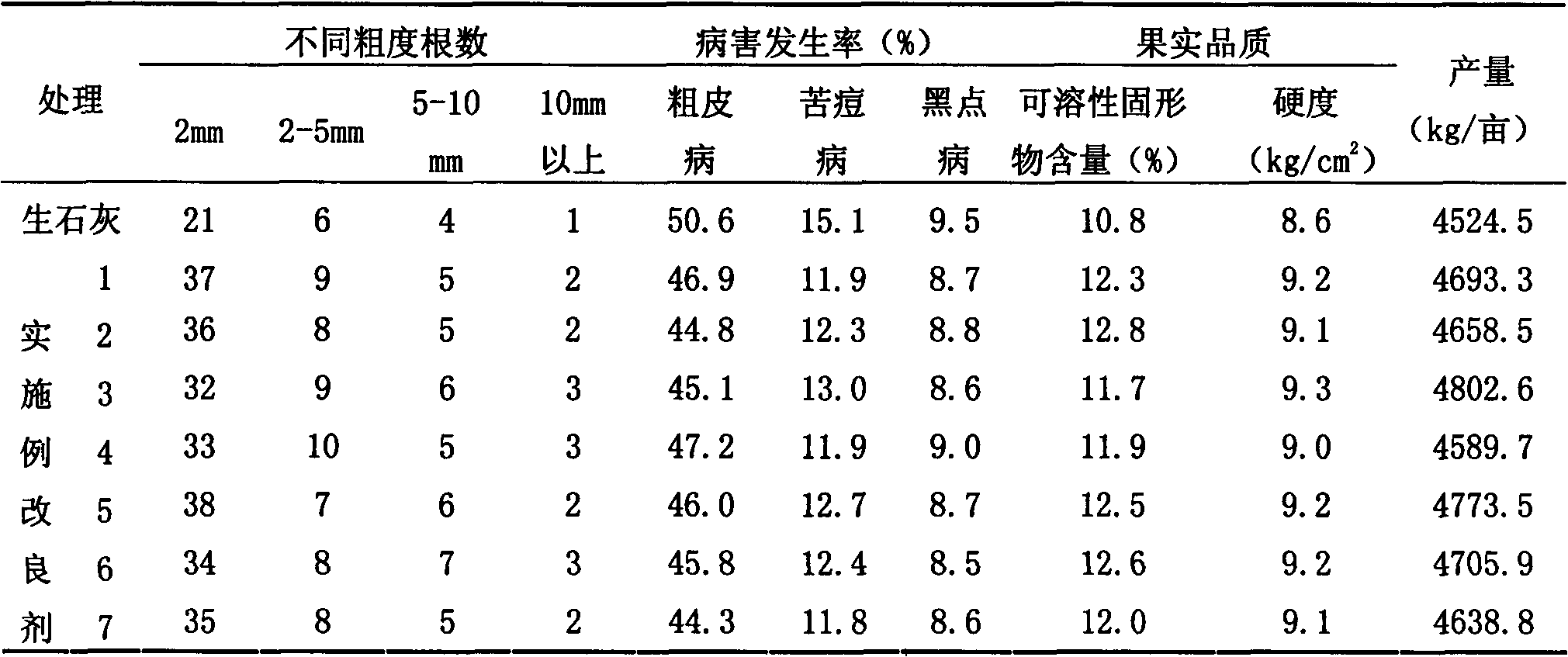

Examples

Embodiment 1

[0051] First put 50 parts by weight of calcium carbonitride into the granulation tray, turn on the turntable, then add 0.5 parts of urease inhibitor, 10 parts of lightly burned powder, 5 parts of ordinary calcium magnesium phosphorus potassium fertilizer, 3 parts of zinc oxide and 5 parts of refined bentonite , and spray pure tap water at the same time, and the cooling cylinder is air-cooled, then it can pass through a 3mm sieve, and then evenly mix with 5 parts of fly ash and 5 parts of slag, and then pack and test before leaving the factory.

Embodiment 2

[0053] First put 50 parts by weight of calcium carbonitride into the granulation tray, turn on the turntable, then add 1 part of urease inhibitor, 18 parts of lightly burned powder, 7 parts of ordinary calcium magnesium phosphorus potassium fertilizer, 5 parts of zinc oxide and 6 parts of refined bentonite, At the same time, water is sprayed, and the cooling cylinder is air-cooled, and then it can pass through a 3mm sieve, and then it is evenly mixed with 5 parts of fly ash and 8 parts of slag, and it is packaged and inspected before leaving the factory.

Embodiment 3

[0055] First put 55 parts by weight of calcium carbonitride into the granulation tray, turn on the turntable, then add 1 part of urease inhibitor, 12 parts of lightly burned powder, 10 parts of ordinary calcium magnesium phosphorus potassium fertilizer, 5 parts of zinc oxide and 6 parts of refined bentonite, At the same time, water is sprayed, and the cooling cylinder is air-cooled, and it can pass through a 3mm sieve, and then it is evenly mixed with 6 parts of fly ash and 5 parts of slag, and it is packaged and inspected before leaving the factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com