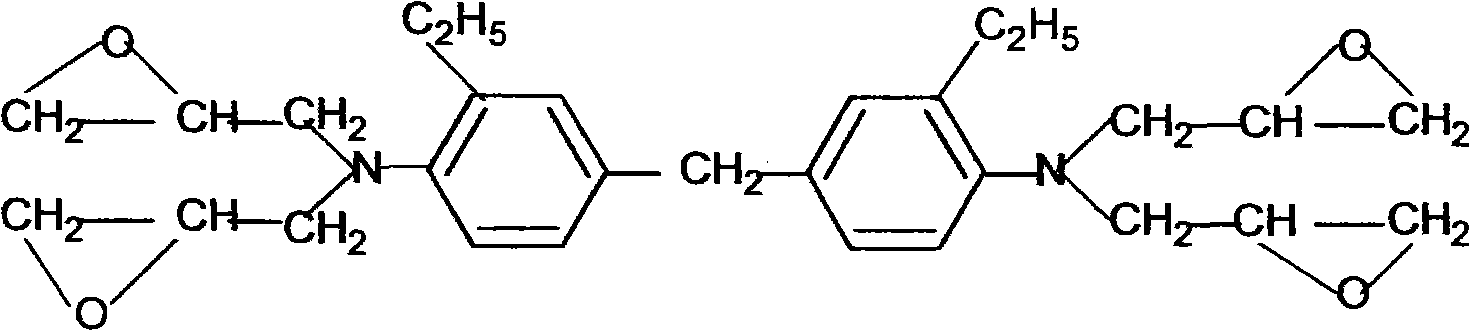

Preparation method of tetraglycidyl-3,3'-diethyl-4,4'-diaminodiphenyl-methane

A technology of diaminodiphenylmethane and tetraglycidyl, which is applied in the field of preparation of tetraglycidylamine compounds, and can solve problems such as difficult separation, high cost of catalyst application, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 254g (1mol) 3,3'-diethyl-4,4'-diaminodiphenylmethane, 740g (8mol) epichlorohydrin, trichloro Cobalt acetate 2g, 78g ethylene glycol and 45g water, after stirring and dissolving, be warming up to 60 ℃ and react for 7 hours, then add 320g acetone and 412g 30% by weight aqueous potassium carbonate solution and react at 55 ℃ for 5 hours, then add 900ml toluene to extract four Glycidyl-3,3'-diethyl-4,4'-diaminodiphenylmethane, steam out toluene, the product is reddish liquid resin, its performance is: epoxy value is 0.72 equivalent / 100 grams, The viscosity is 0.48Pa.s at 25°C.

[0019] 10g tetraglycidyl-3,3'-diethyl-4,4'-diaminodiphenylmethane product, 5g4,4'-diaminodiphenylsulfone and 0.3g fumed silicon dioxide were mixed together and placed in Cured at 160°C for 2 hours, cured at 210°C for 2 hours, the heat distortion temperature was 182.1°C, the impact modulus of the cast sample was 3.2Gpa, and the Rockwell hardness E 85.

Embodiment 2

[0021] Except epichlorohydrin 462.5g (5mol), potassium nitrate 1.3g, 1.2-propanediol 70g, water 40g, addition reaction at 50°C for 6 hours, add 373g of 30wt% sodium hydroxide aqueous solution, cyclization reaction at 50°C for 4 hours, Except adding 800ml of toluene for extraction, other charging amount reaction control parameters are the same as embodiment 1, the result epoxy value is 0.70 equivalent / 100 grams, viscosity 25℃ 0.40Pa.s, after 4,4'-diaminodiphenyl sulfone is cured, the performance index is also the same as that of Example 1.

Embodiment 3

[0023] Except epichlorohydrin 925g (10mol), glycerin 85g, cobalt monochloroacetate 2.5g, water 50g, add reaction at 70 ℃ for 4 hours, add 30wt% sodium hydroxide aqueous solution 247g and 30wt% potassium carbonate aqueous solution 165g, Carry out cyclization reaction at 60 DEG C for 3 hours, add 1000mol toluene to extract, other charging amount, reaction control parameter are the same as embodiment 1, the result epoxy value is 0.74 equivalent / 100 grams, viscosity 25℃ It is 0.51Pa.s, and the performance index is also the same as that of Example 1 after curing by 4,4'-diaminodiphenyl sulfone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com