Strip for connecting and/or sealing a joint

A technology for sealing joints and strips, used in engine sealing, film/flake adhesives, chemical instruments and methods, etc., can solve problems such as insufficient strip adhesion, gas or fluid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

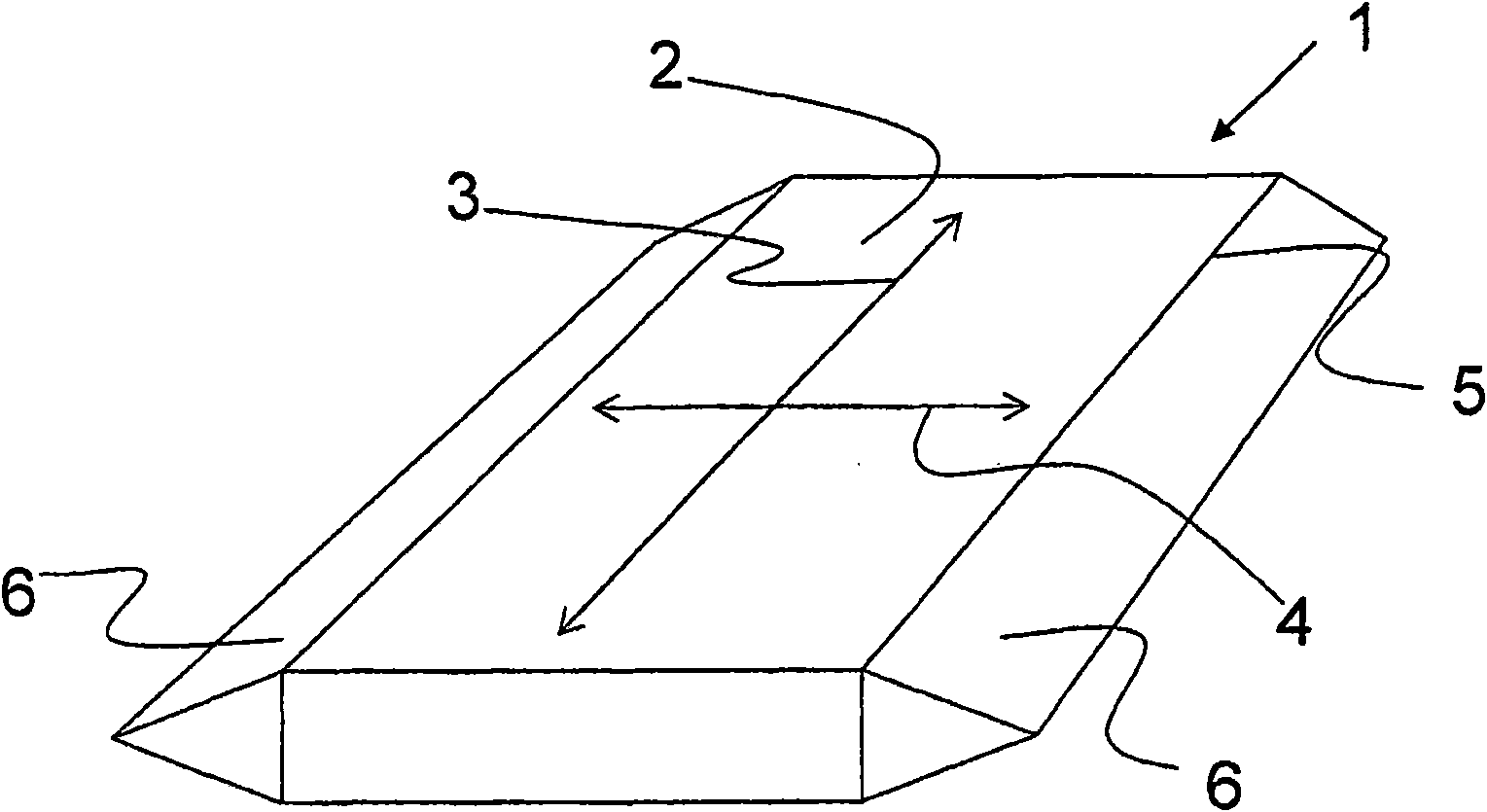

[0064] figure 1 The strip 1 according to the invention is shown in a perspective view. The strip 1 has a first surface 2 and a second surface (not shown) with a longitudinal extension 3 and a transverse extension 4 with longitudinal sides 5 .

[0065] According to the invention, at least one of the longitudinal sides 5 comprises an edge part 6 providing a chamfer during connection and / or sealing of a joint (not shown). exist figure 1 , Stripe 1 is shown in the unapplied state.

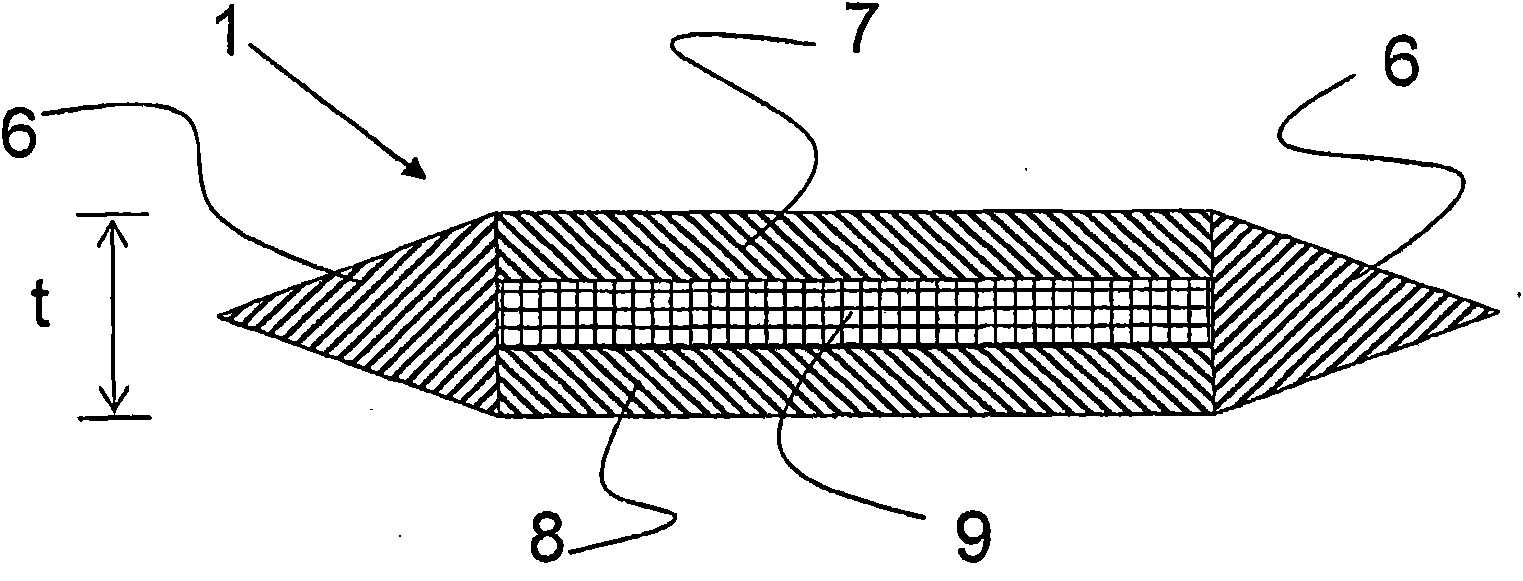

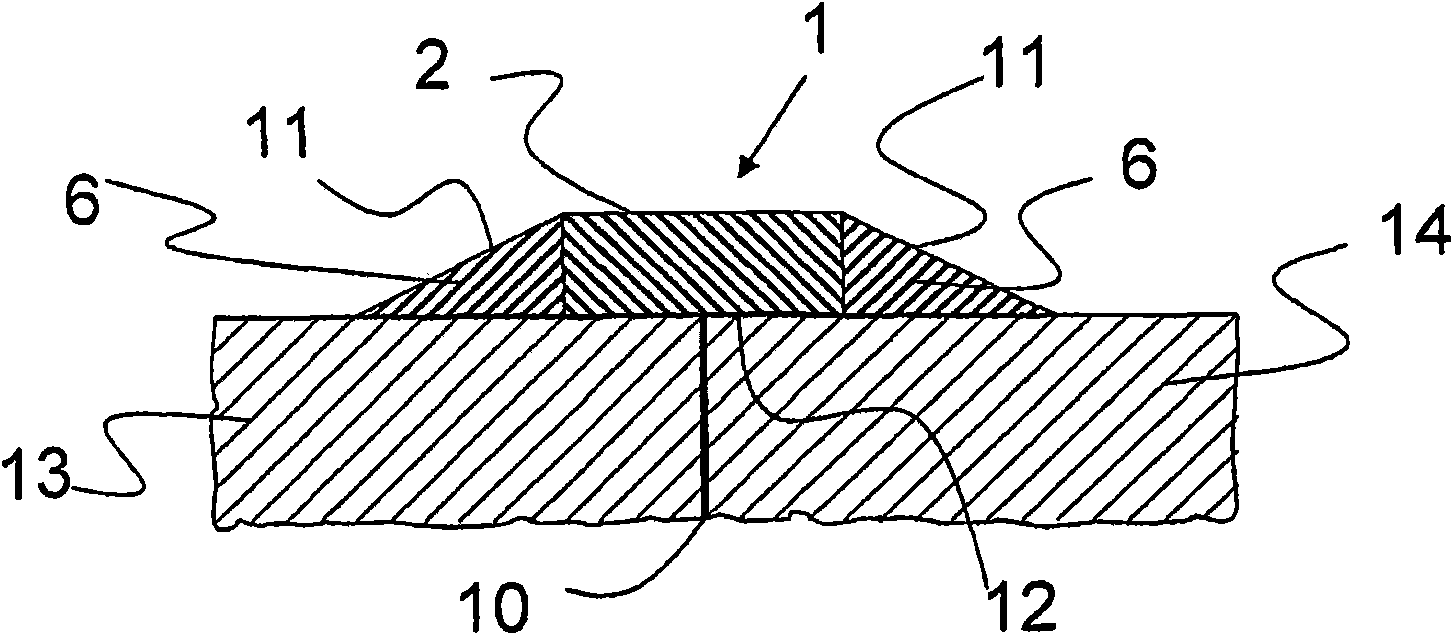

[0066] exist figure 2 In , an example of a cross-section of a strip 1 according to the invention is shown before being applied to a joint. In this embodiment, the strip 1 has a thickness t, which is preferably between 0.05 mm and 30.00 mm. Furthermore, the edge part 6 of the strip 1 is symmetrical in this embodiment and has a right-triangular configuration.

[0067] In other not shown embodiments, the edge member may have a triangular, circular, square, semicircular, curved or oval cross-section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com