Blade-type hydraulic transformer controlled by motor

A hydraulic transformer and motor control technology, which is applied in the field of hydraulic transformers and vane hydraulic transformers, to achieve the effects of expanding the application range, easy and precise control, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

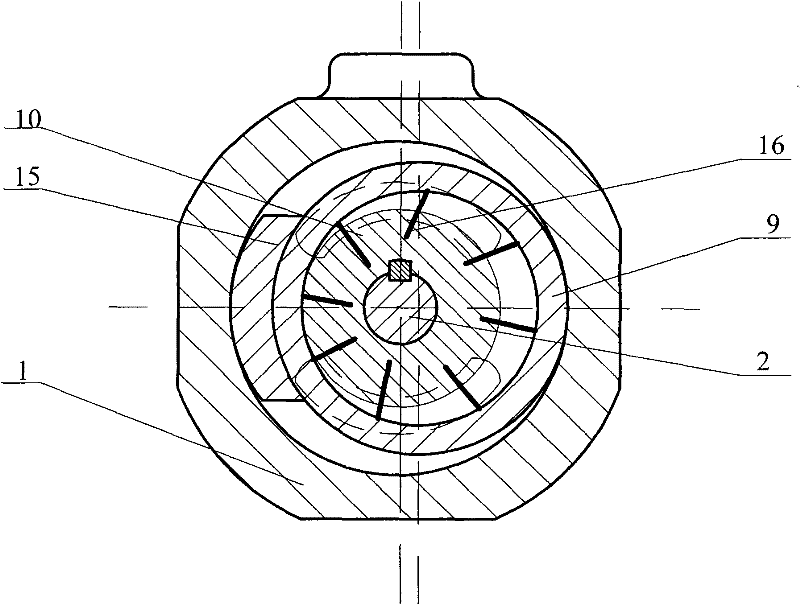

[0020] like figure 1 , 2 , 3, and 4, the vane hydraulic transformer controlled by the motor of the present invention is mainly composed of a housing 1, a rotating shaft 2, a left end cover 3, a first group of flow plates 4, 7 and a first stator 5, a first The rotor 6, the second group of distribution plates 8, 11, the second stator 9, the second rotor 10, the right end cover 12, the gear 13, the first group of blades 14, the wedge plate 15, the second group of blades 16, the motor 17, etc.; The centers of the first rotor 6 and the first stator 5 are fixed and coincident, the width of the first rotor 6 is slightly smaller than the width of the first stator 5, the first rotor 6 is installed in the first stator 5, the first One end of the set of blades 14 is put into the blade groove of the first rotor 6, and the other end is in contact with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com