Mobile regenerated asphalt mixture cold mixing device

A technology of recycled asphalt and mixing equipment, which is applied in the directions of roads, road repair, roads, etc., can solve the problems of high equipment cost and use cost, flue gas pollution, etc., and achieve the effect of low manufacturing cost, reasonable layout and less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

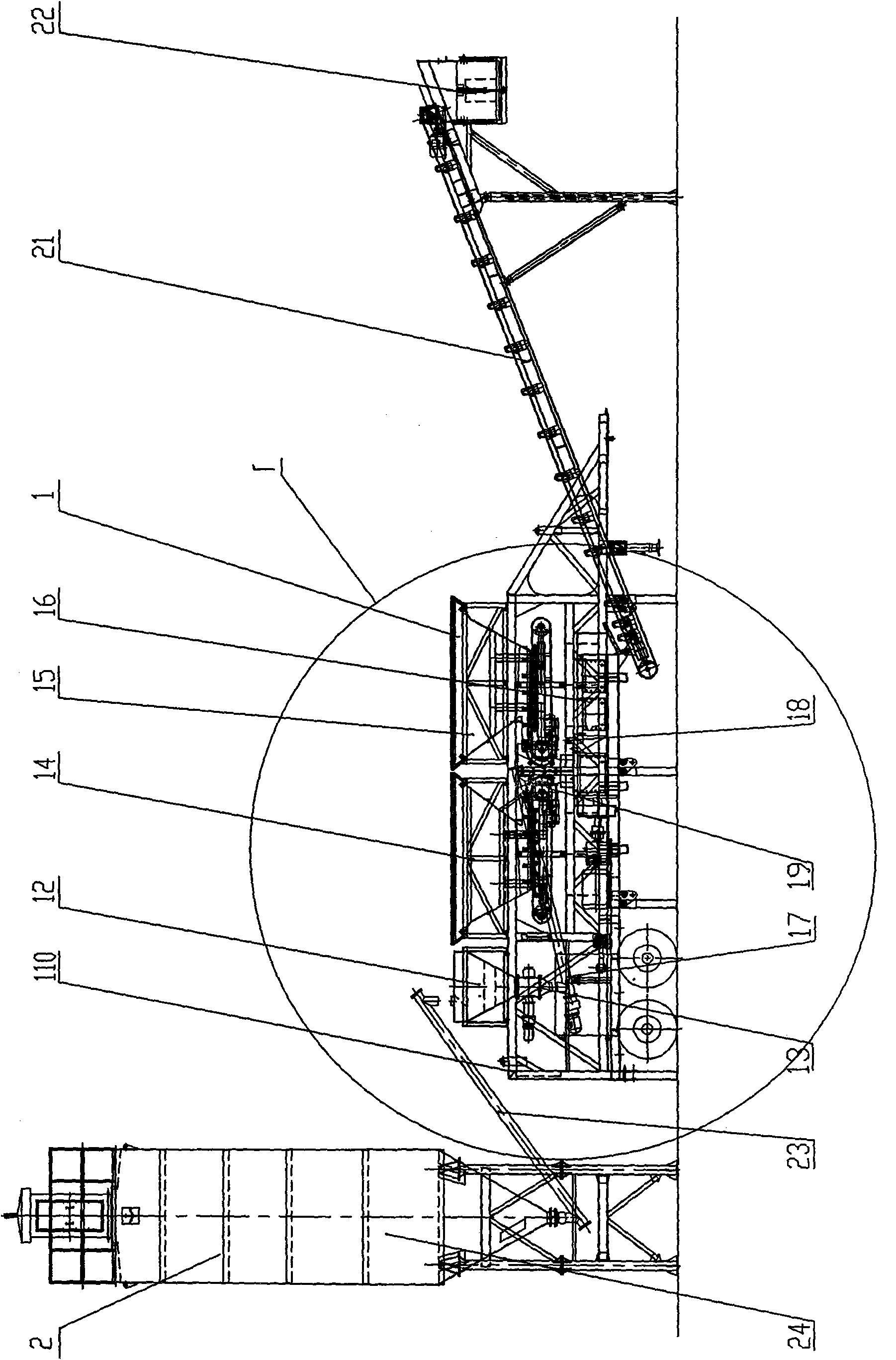

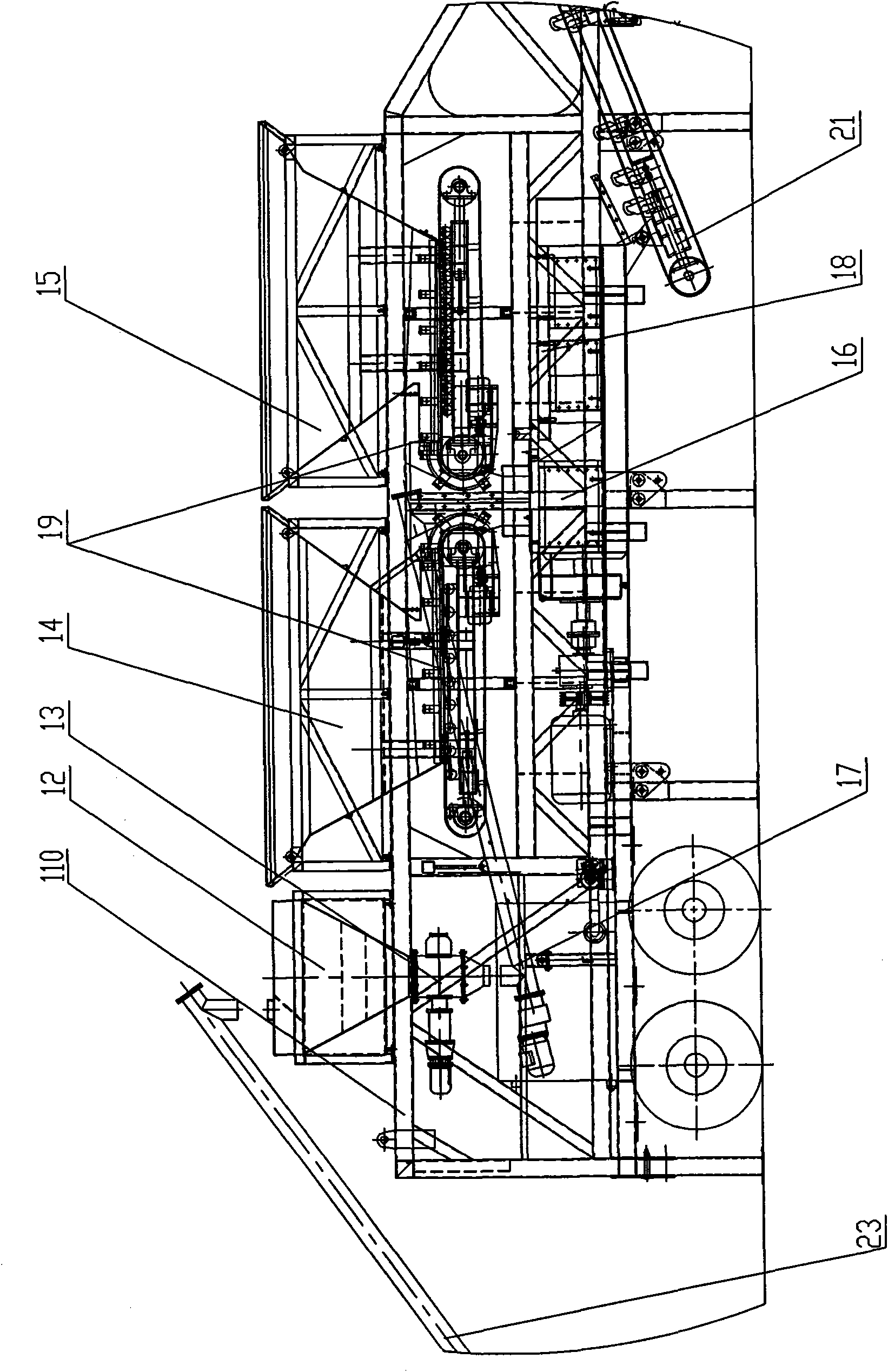

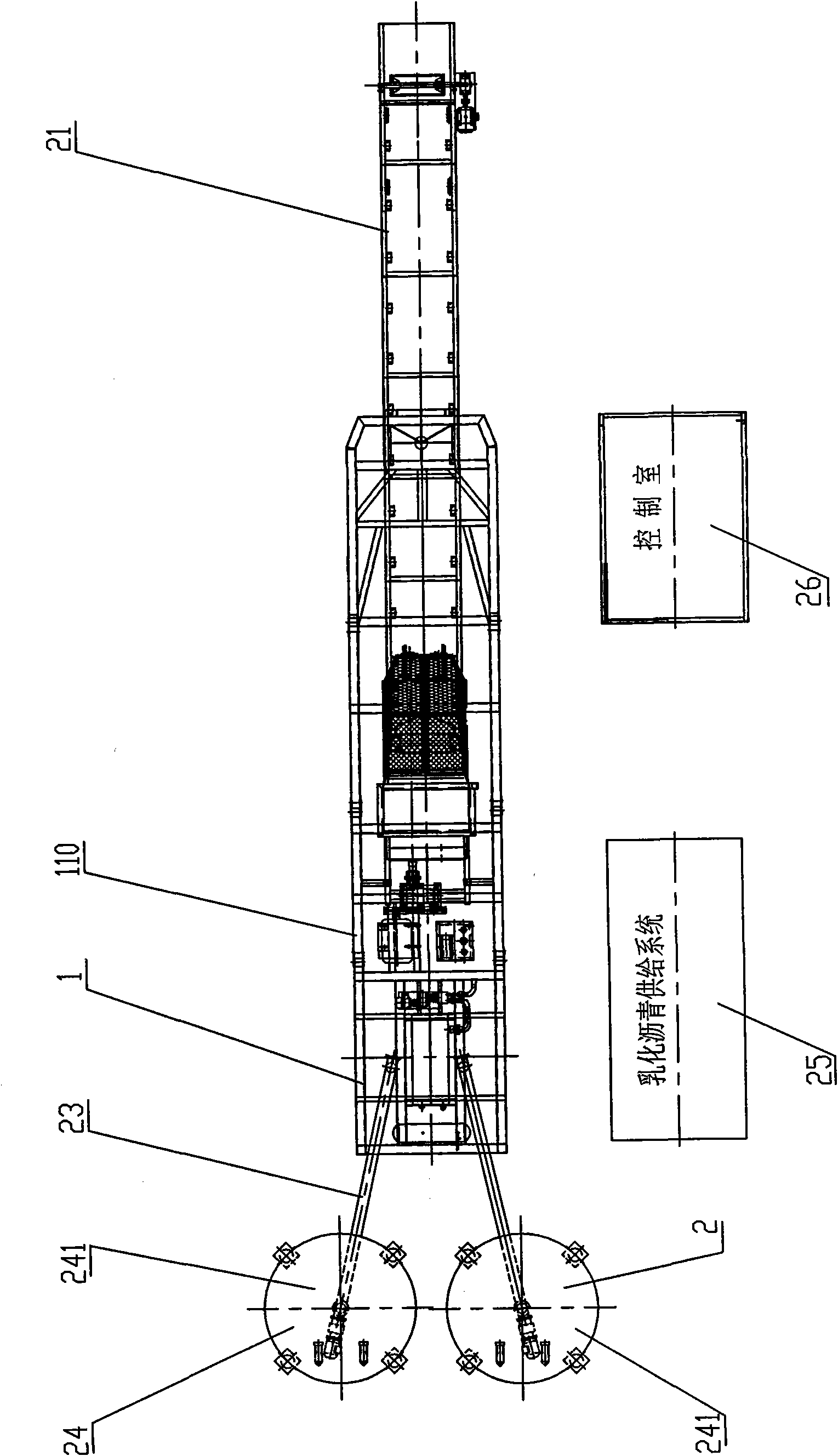

[0025] Such as Figure 1 ~ Figure 3 As shown, the present invention includes a mobile semi-hanging unit 1 and a fixed hanging unit 2 . The mobile semi-trailer unit includes a semi-trailer chassis 110, a powder hopper 12 installed on the top of the semi-trailer chassis 110, a single aggregate hopper 14 and a double aggregate hopper 15, an impeller feeder 17 installed at the bottom of the powder hopper 12, The screw conveyor 13 arranged at the exit of the impeller feeder 17, the three aggregate feed conveyors 19 respectively arranged under the bottom of the single aggregate hopper 14 and the double aggregate hopper 15, are arranged in the mobile semi-hanging unit 1 The water supply system 11 of the front lower part is installed in the mixing cylinder 16 of the underframe 1 bottom, and the asphalt nozzle 254 is contained in the mixing cylinder 16 top. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com