Manufacturing method of atmosphere corrosion resistance steel

A technology of atmospheric corrosion-resistant steel and production methods, which is applied in the field of iron and steel smelting, can solve problems such as high cost and complex production process, and achieve the effects of improving production efficiency, shortening procedures, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

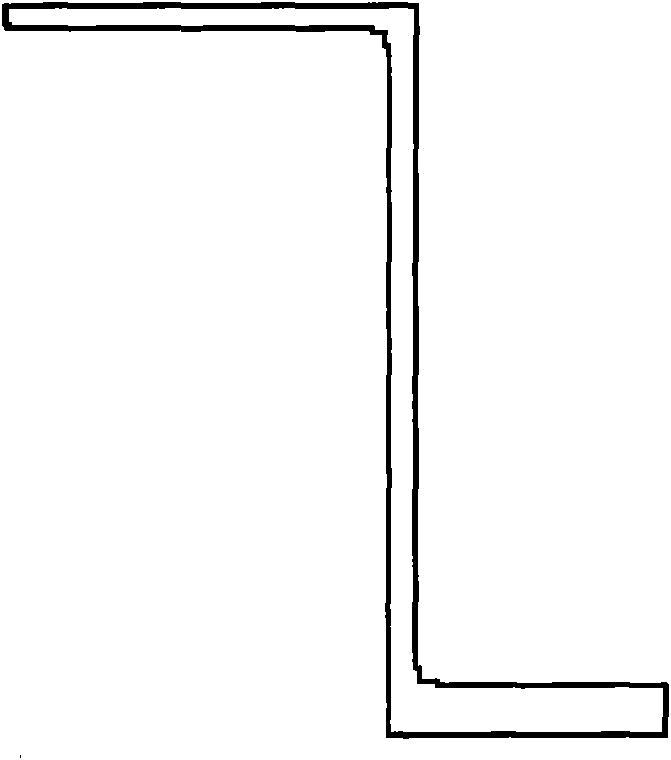

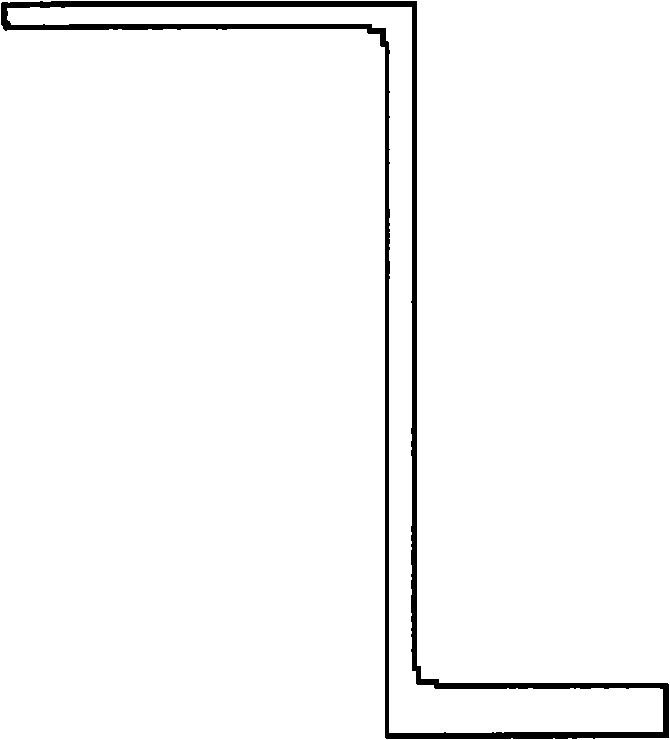

[0041] A certain iron and steel plant adopts the present invention to produce appearance as figure 1 High-strength atmospheric corrosion-resistant steel.

[0042] First, 141 tons of molten iron with a C content of 4.5% was added to the converter, and the actual tapping amount was 135 tons, of which about 6 tons of molten iron was burned, and then oxygen was blown in for smelting, and Cu and Ni were added 4 minutes before the end of the converter smelting molten steel plate, so that the contents of Cu and Ni in the molten steel are 0.25% and 0.15% respectively. When the C content in the converter molten steel is less than 0.05%, the steel is immediately tapped into the ladle. At this time, the measured value of the chemical composition of the molten steel is C 0.03 %, P 0.015%, S 0.010%.

[0043] Add 1.0 tons of lime and fluorite when 1 / 3 of the steel is tapped, including 800kg of lime and 200kg of fluorite; add 340kg of aluminum pre-deoxidizer Fe-Al; add Fe-Si-Mn alloy, Fe-Si...

Embodiment 2

[0049] A certain iron and steel plant adopts the present invention to produce appearance as figure 1 High-strength atmospheric corrosion-resistant steel.

[0050] First, 135.5 tons of molten iron with a C content of 4.0% is added to the converter, and the actual tapping amount is 130 tons, of which about 5.5 tons of molten iron is burned, and then oxygen is blown in for smelting, and Cu and Ni plates are added 2 minutes before the completion of molten steel smelting in the converter , so that the contents of Cu and Ni in molten steel are respectively 0.20% and 0.15%. When the C content in converter molten steel is less than 0.05%, the steel is tapped into the ladle immediately. At this time, the measured values of the chemical composition of molten steel are C 0.04%, P 0.018%, S 0.011%.

[0051] Add 1.0 tons of lime and fluorite when 1 / 3 of the steel is tapped, including 800kg of lime and 200kg of fluorite; add 320kg of aluminum pre-deoxidizer Fe-Al, add Fe-Si-Mn alloy, Fe-...

Embodiment 3

[0058] A steel plant adopts this technology in the converter process to produce the appearance as figure 1 High-strength atmospheric corrosion-resistant steel.

[0059] First, 134 tons of molten iron with a C content of 4.0% was added to the converter, and the actual tapping amount was 129 tons, of which about 5 tons of molten iron was burned, and then oxygen was blown in for smelting, and Cu and Ni plates were added 5 minutes before the completion of molten steel smelting in the converter , so that the contents of Cu and Ni in molten steel are respectively 0.35% and 0.25%. When the C content in converter molten steel is less than 0.05%, the steel is immediately tapped into the ladle. At this time, the measured values of the chemical composition of molten steel are C 0.05%, P 0.020%, S 0.015%.

[0060] When 1 / 3 of the steel is tapped, 1.0 tons of lime and fluorite (including 800kg of lime and 200kg of fluorite), 320kg of Fe-Al, Fe-Si-Mn alloy, Fe-Si and Fe-Cr alloy are adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com