Novel heat insulation protective layer structure of furnace roller and preparing method thereof

A technology of heat insulation protection and layer structure, applied in the field of smelting equipment, can solve the problems of heavy refractory castables, heavy use conditions of furnace rolls, increased consumption costs of furnace rolls, etc., and achieves light weight, low cost and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

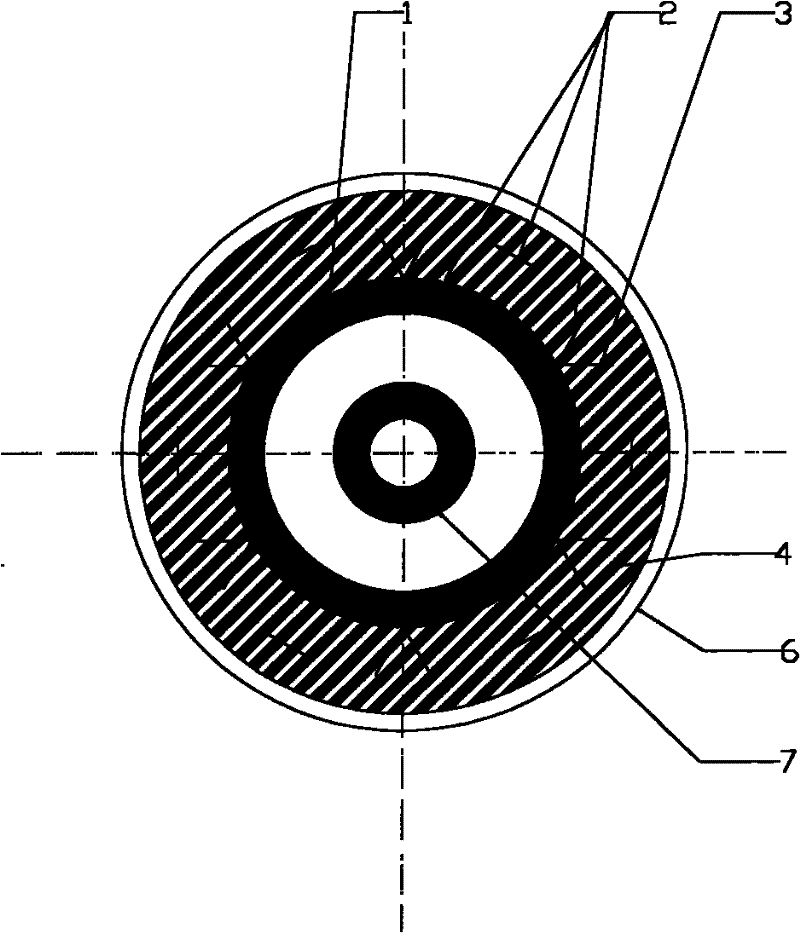

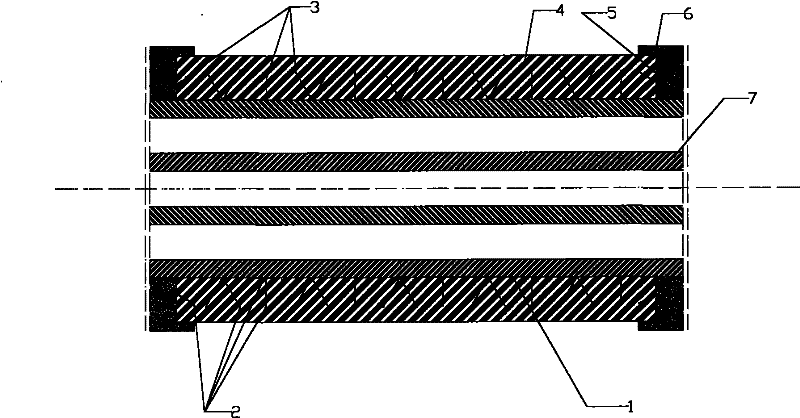

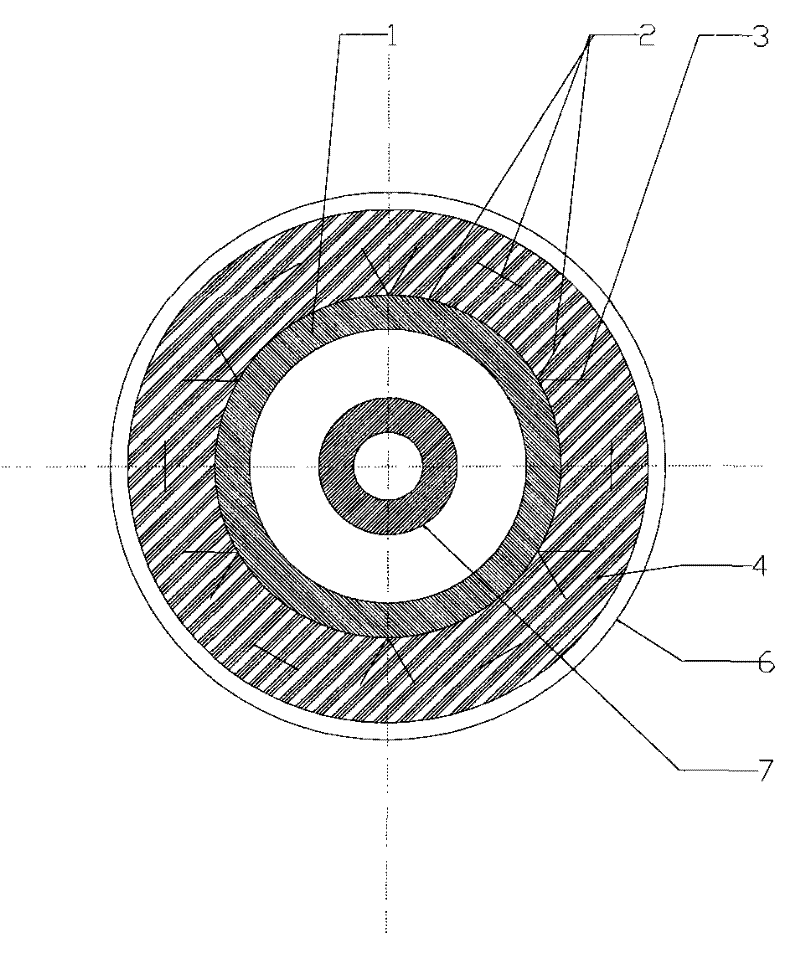

[0013] Embodiment 1: A new type of heat insulation protection structure for furnace rollers, such as figure 1 , shown in 2, consists of roll body (1), organic buffer coating (2), special-shaped metal anchor (3), castable layer (4), roll ring concave surface (5), roll ring (6), cooling water Conduit (7) constitutes. The organic buffer coating (2) is formed by brushing with an organic paint. The organic paint is prepared by stirring and mixing the raw materials of machine oil 95, diesel oil 4, and polypropylene powder 1 in percentage by weight (%), respectively on the roller body (1 ) and the special-shaped metal anchor (3) are painted on the surface to make an organic buffer coating. The special-shaped metal anchor (3) is composed of a V-shaped metal anchor, a double V-shaped metal anchor and a roller ring small V-shaped metal anchor. The V-shaped metal anchor is made of ordinary carbon steel wire rod with a diameter of 6mm, the height is 55% of the thickness of the cast laye...

Embodiment 2

[0015] Embodiment 2: A new type of heat insulation protection structure for furnace rollers, such as figure 1 , shown in 2, consists of roll body (1), organic buffer coating (2), special-shaped metal anchor (3), castable layer (4), roll ring concave surface (5), roll ring (6), cooling water Conduit (7) constitutes. The organic buffer coating (2) is formed by brushing with an organic paint. The organic paint is prepared by stirring and mixing the raw materials of machine oil 85, diesel oil 10, and polyacrylonitrile powder 5 by weight percentage, respectively on the roller body ( 1) and the surface of the special-shaped metal anchor (3) is brushed to make an organic buffer coating. The special-shaped metal anchor (3) is composed of a V-shaped metal anchor, a double V-shaped metal anchor and a roller ring small V-shaped metal anchor. The V-shaped metal anchor is made of ordinary carbon steel wire rod with a diameter of 5mm, the height is 70% of the thickness of the pouring laye...

Embodiment 3

[0016] Embodiment 3: A new type of heat insulation protection structure for furnace rollers, such as figure 1 , shown in 2, consists of roll body (1), organic buffer coating (2), special-shaped metal anchor (3), castable layer (4), roll ring concave surface (5), roll ring (6), cooling water Conduit (7) constitutes. The organic buffer coating (2) is formed by brushing with an organic paint. The organic paint is prepared by stirring and mixing the raw materials of machine oil 90, diesel oil 7, and polypropylene powder 3 in percent by weight, respectively on the roller body (1 ) and the special-shaped metal anchor (3) are painted on the surface to make an organic buffer coating. The special-shaped metal anchor (3) is composed of a V-shaped metal anchor, a double V-shaped metal anchor and a roller ring small V-shaped metal anchor. The V-shaped metal anchor is made of ordinary carbon steel wire rod with a diameter of 5.5mm, the height is 60% of the thickness of the cast layer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com