Front and back driving force output structure of automobile tractor without independent transfer case

A technology of output structure and power output end, which is applied in vehicle components, transportation and packaging, control devices, etc., can solve the problems of increased technical difficulty in the design and layout of the whole vehicle, complicated device structure, and large material consumption, and is conducive to the design and layout. The effect of simplifying the gearshift operating mechanism and reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

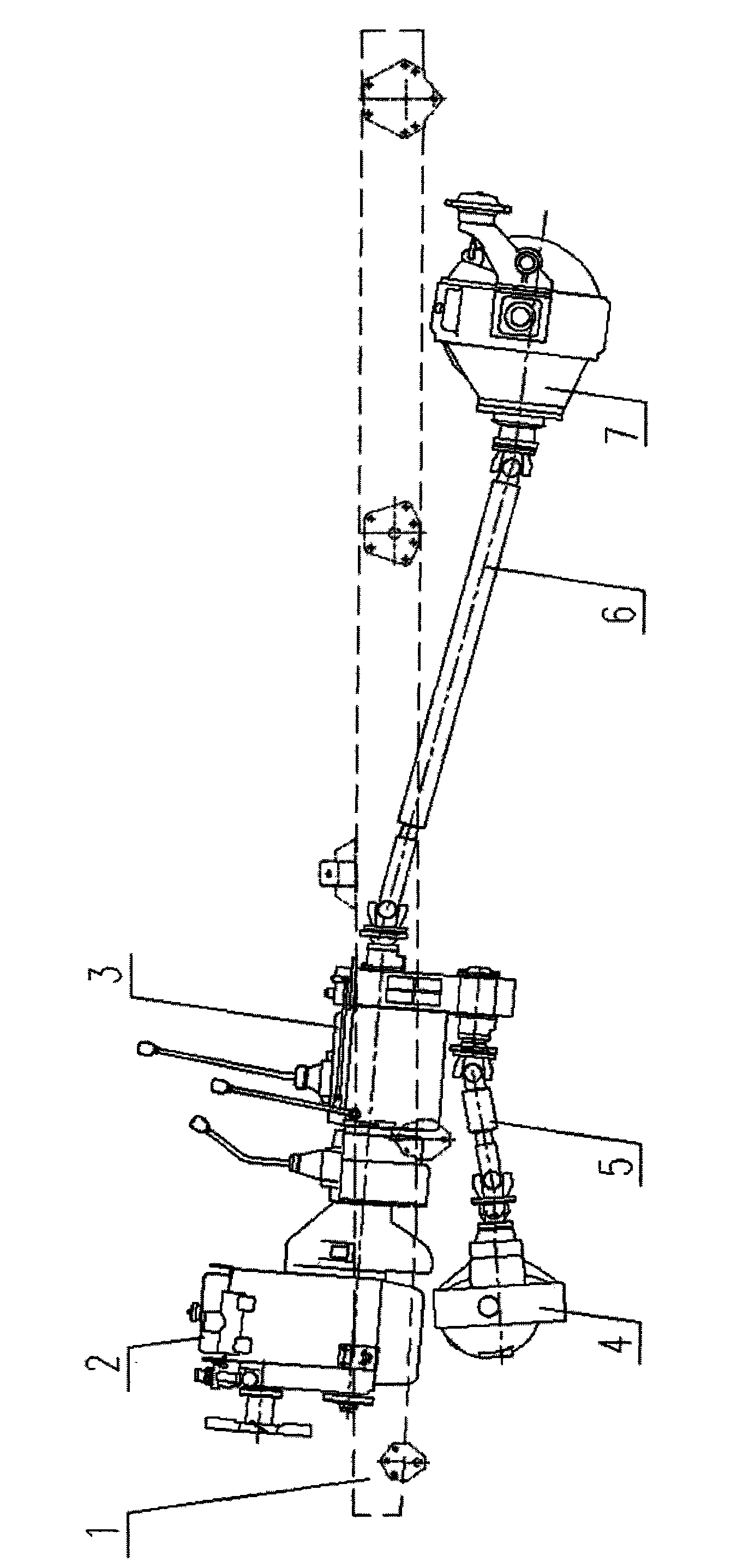

[0010] refer to figure 1 , the present invention is made up of vehicle frame 1, engine 2, combined transmission 3, front axle 4, front transmission shaft 5, rear transmission shaft 6 and rear axle 7, the combined transmission 3 with front and rear output is arranged on the power output end of engine 2, The forward power output end of the combined transmission 3 is connected with the front axle 4 through the front drive shaft 5, and the rearward power output end is connected with the rear axle 7 through the rear drive shaft 6, forming an automobile tractor front and rear without an independent transfer case. The driving force output structure, the forward or backward power output of the shift lever of the combined transmission 3 is manipulated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com