Drum type washing machine

A drum-type washing machine, washing machine shell technology, applied to other washing machines, synchronous machines, washing devices, etc., can solve the problem of increased radial force, increased vibration and noise, and it is difficult to increase capacity, miniaturization, and mute. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

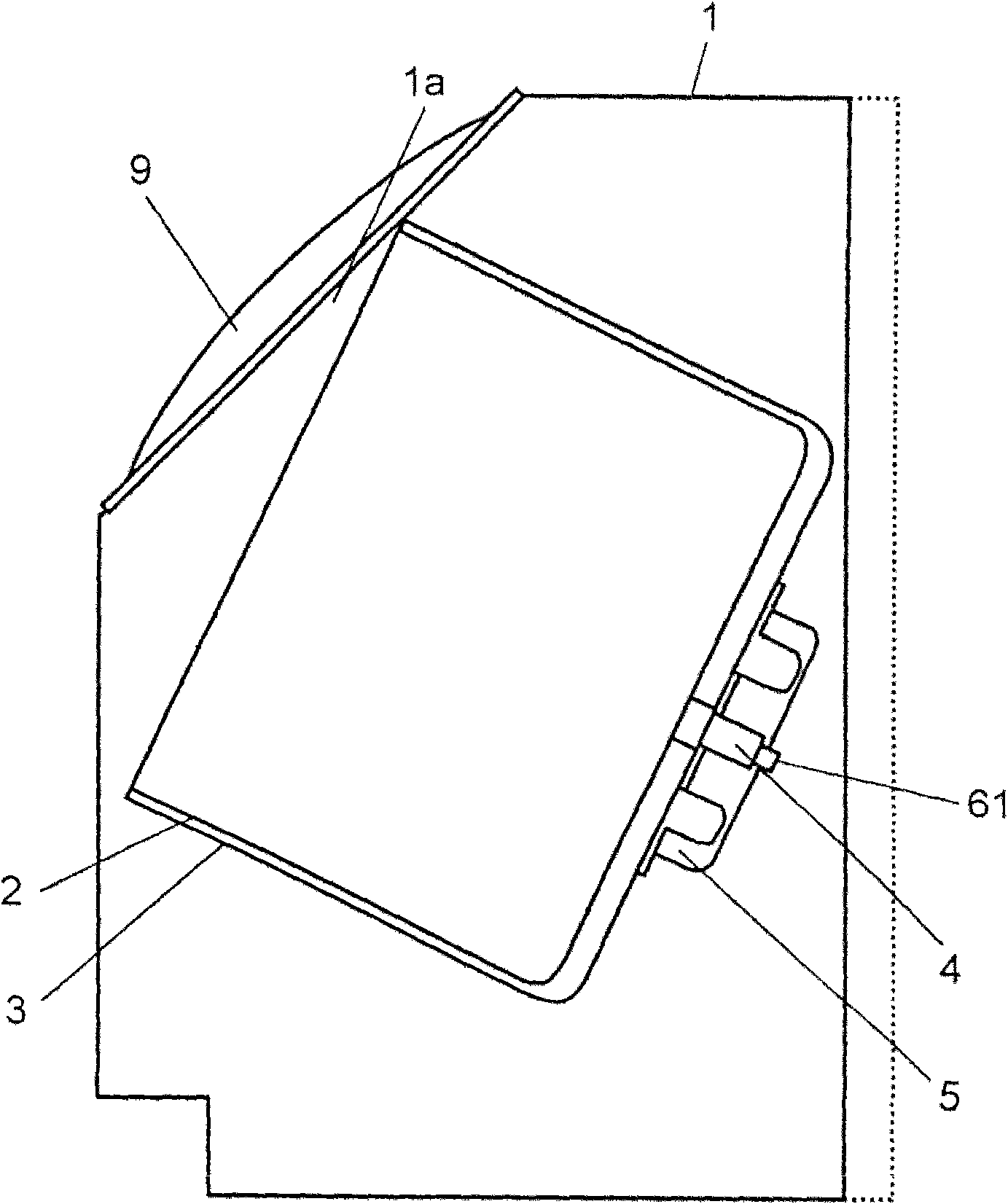

[0060] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a cross-sectional view of the front-loading-type washing machine according to the embodiment of the present invention.

[0061] Bottomed cylindrical tub 3 is disposed in washing machine casing 1 of the front-loading washing machine in a state inclined downward from the front side of main body 1 toward the back side. The tub 3 rotatably supports a bottomed cylindrical rotary drum 2 inside the tub 3 such that the drum rotating shaft 4 is inclined downward from the front side toward the back side of the washing machine casing 1 .

[0062] An opening 1a for taking out and putting in laundry is formed on the front side of the washing machine casing 1 . On the opening portion 1a, a cover 9 made of a material such as glass for opening and closing the opening portion 1a is provided.

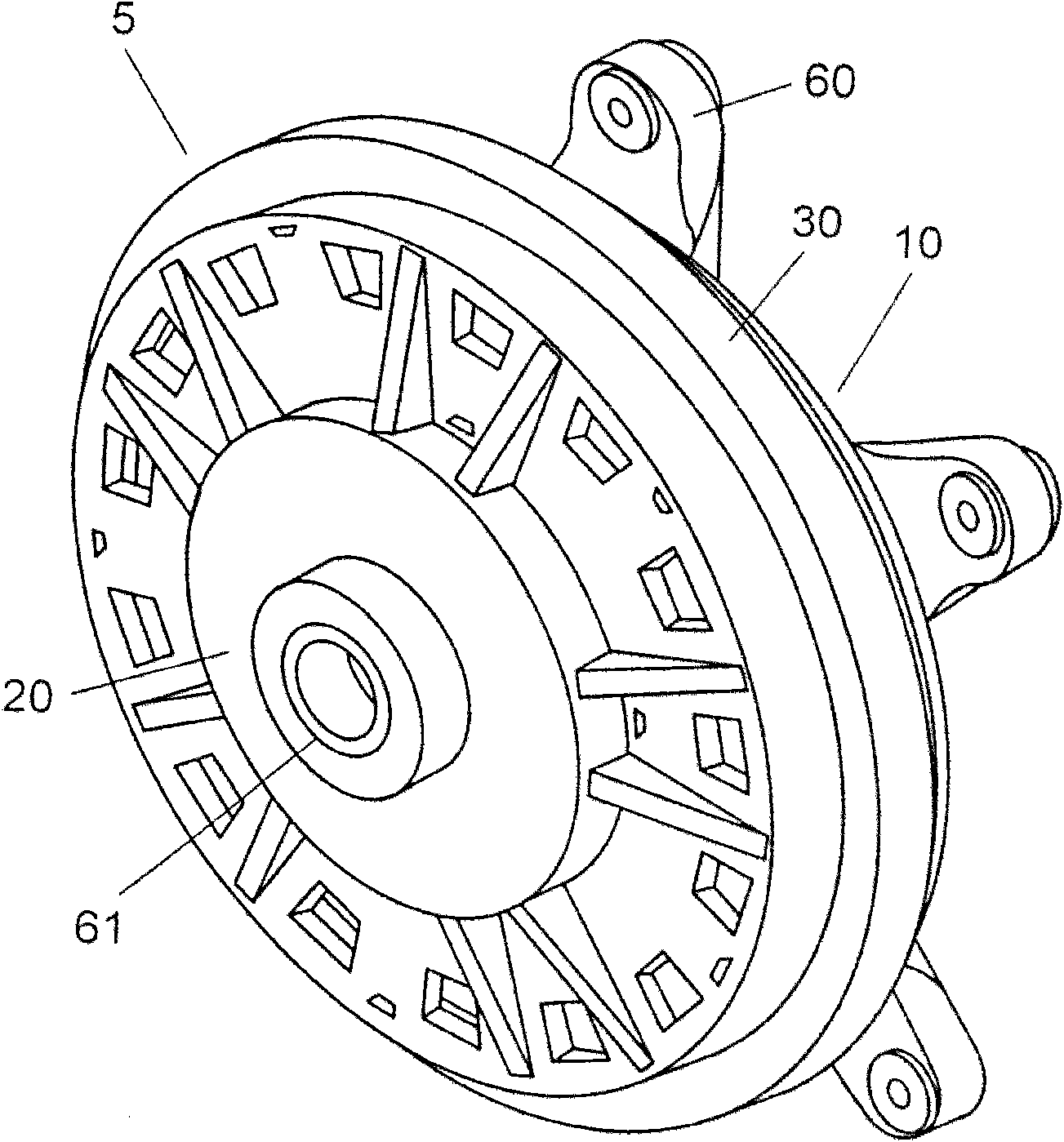

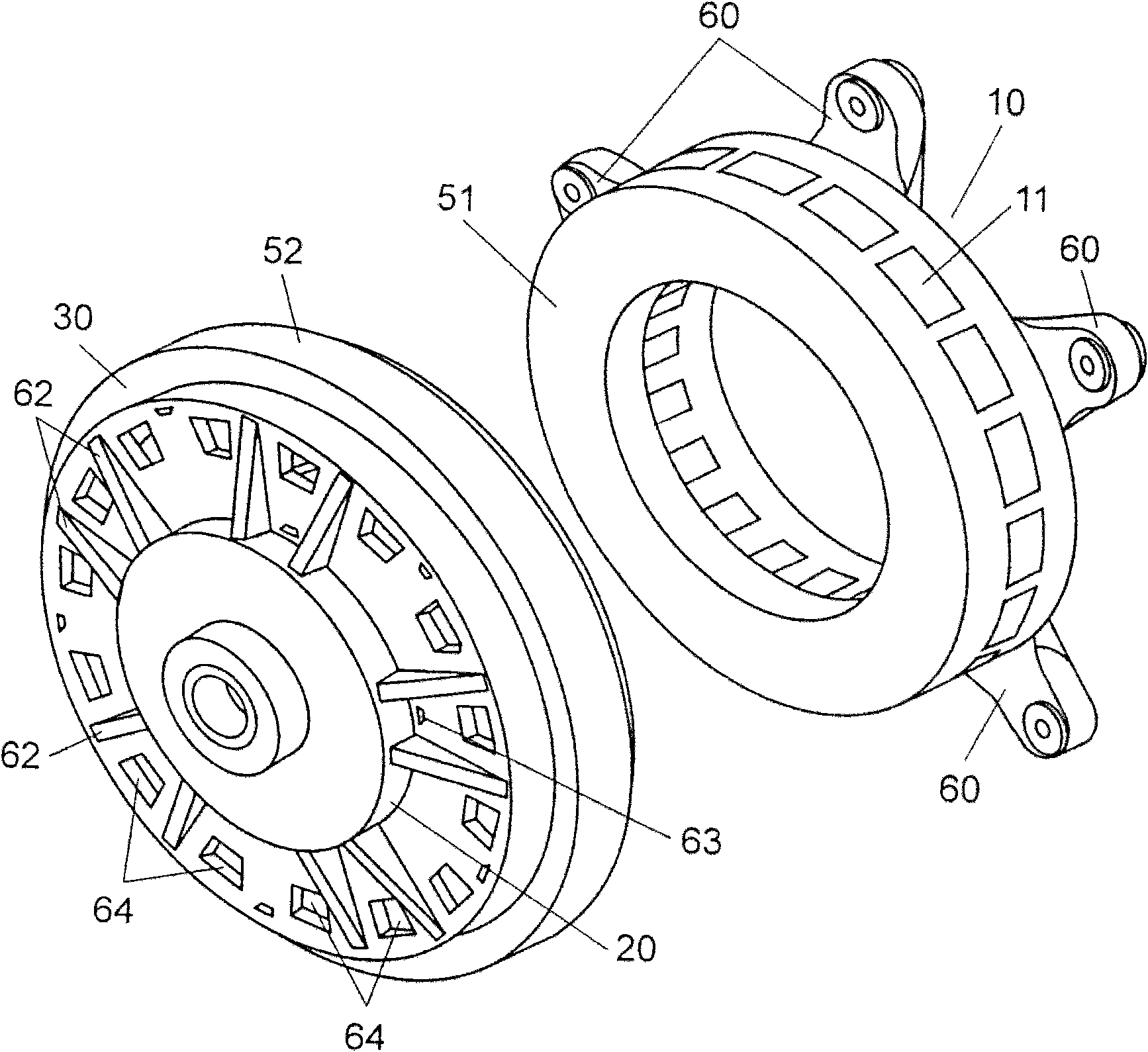

[0063] On the outside of the bottom of tub 3 , motor shaft 61 of motor 5 is dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com