Preparation method of inverse opal hydrogel photonic crystal with hybridized structure

A technology of inverse opal and hybrid structure, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high material cost, limited wide application, and the upper layer pattern display is affected by the background of the lower layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

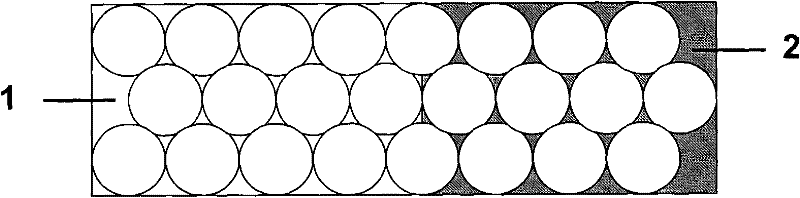

[0011] (1) Disperse the homogeneous monodisperse silica microspheres in ethanol to form a solution with a mass fraction of 4%, then pour the solution into a clean container, and finally insert the clean substrate vertically into the liquid surface The above-mentioned container containing the monodisperse silica microsphere solution is placed in a closed environment at room temperature for one week to deposit the silica microspheres on the surface of the substrate and form opal colloidal crystals on the surface of the substrate; the substrate is Glass or silicon wafer; the diameter of the silica microspheres is 180nm;

[0012] (2) Immerse the base vertical liquid surface of the opal colloidal crystal formed on the surface obtained in step (1) in the polyacrylic acid monomer solution for 3 minutes, the concentration of the polyacrylic acid monomer solution is 5M, and the polyacrylic acid monomer solution contains a mass fraction of 10 % crosslinking agent N, N'-methylenebisacryl...

Embodiment 2

[0015] (1) Disperse the homogeneous monodisperse silica microspheres in ethanol to form a solution with a mass fraction of 1%, then pour the solution into a clean container, and finally insert the clean substrate vertically into the liquid surface The above-mentioned container containing the monodisperse silica microsphere solution is placed in a closed environment at room temperature for one week to deposit the silica microspheres on the surface of the substrate and form opal colloidal crystals on the surface of the substrate; the substrate is Glass or silicon wafer; the diameter of the silica microspheres is 232nm;

[0016] (2) Immerse the base vertical liquid surface of the opal colloidal crystal formed on the surface obtained in step (1) in the polyacrylic acid monomer solution for 3 minutes, the concentration of the polyacrylic acid monomer solution is 4M, and the polyacrylic acid monomer solution contains 5 % crosslinking agent N, N'-methylenebisacrylamide and 3% photoin...

Embodiment 3

[0019] (1) Disperse the homogeneous monodisperse silica microspheres in ethanol to form a solution with a mass fraction of 0.5%, then pour the solution into a clean container, and finally insert the clean substrate vertically into the liquid surface The above-mentioned container containing the monodisperse silica microsphere solution is placed in a closed environment at room temperature for one week to deposit the silica microspheres on the surface of the substrate and form opal colloidal crystals on the surface of the substrate; the substrate is Glass or silicon wafer; the diameter of the silica microspheres is 300nm;

[0020] (2) Immerse the base vertical liquid surface of the opal colloidal crystal formed on the surface obtained in step (1) in the polyacrylic acid monomer solution for 3 minutes, the concentration of the polyacrylic acid monomer solution is 1M, and the polyacrylic acid monomer solution contains a mass fraction of 1 % crosslinking agent N, N'-methylene bisacr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com