Soundproof room of rotating hub and use method thereof

A technology for sound insulation rooms and chambers, which is applied in the testing of measuring devices, instruments, vehicles, etc., can solve the problems of low detection efficiency, high noise in the air supply and exhaust system, and increase in the cost of sound insulation rooms, so as to reduce investment and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

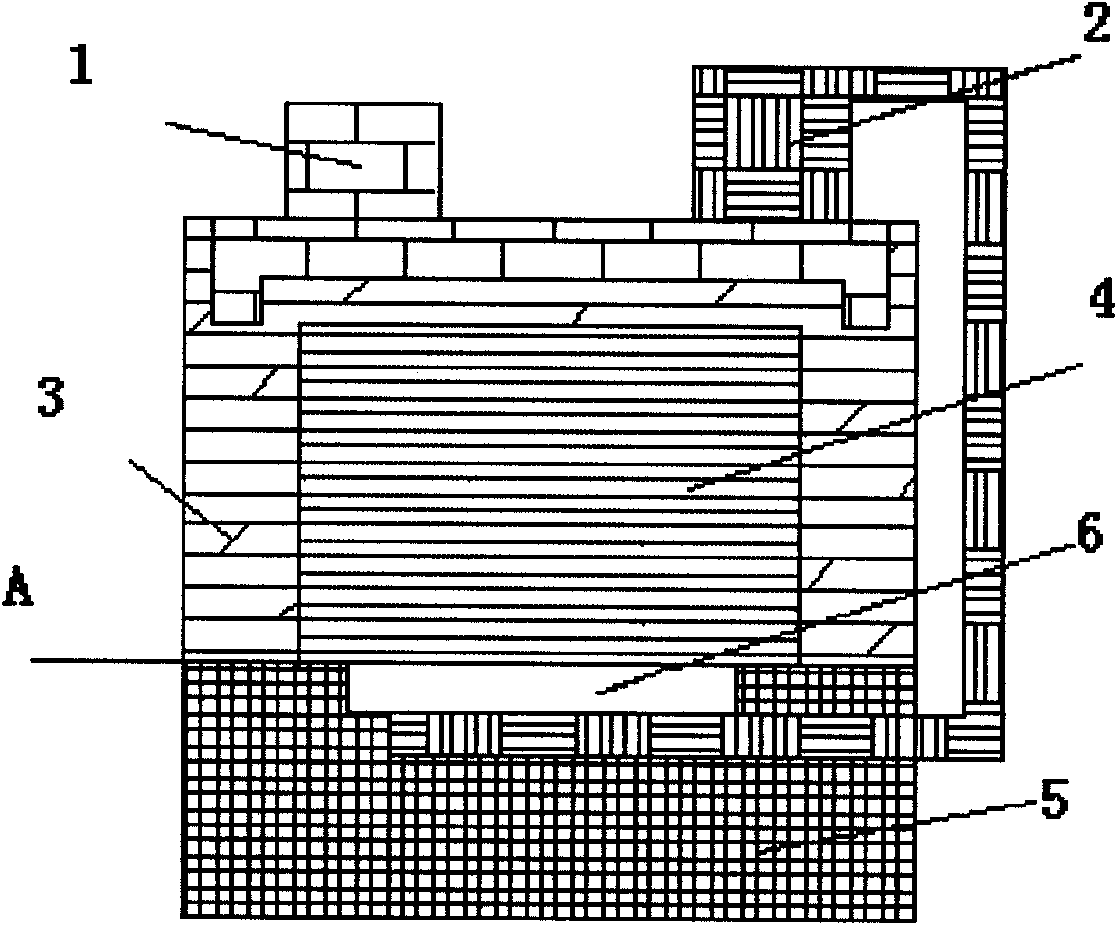

[0025] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

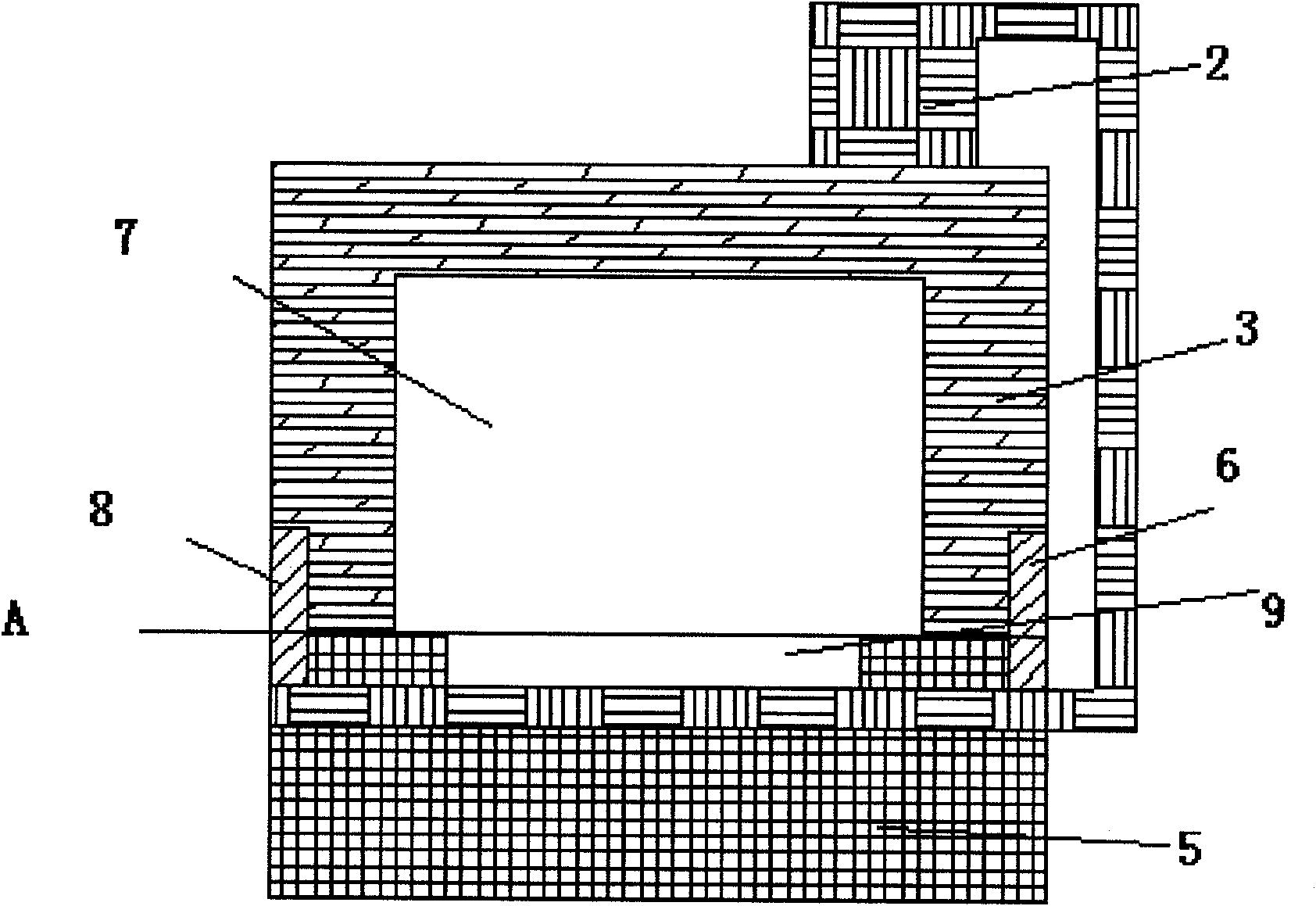

[0026] The present invention cancels the automatic lifting door or automatic folding door in the prior art, and replaces it with an open door 7, and cancels the air supply system in the original solution. Two air intakes 8 and 9 have been newly added in the body.

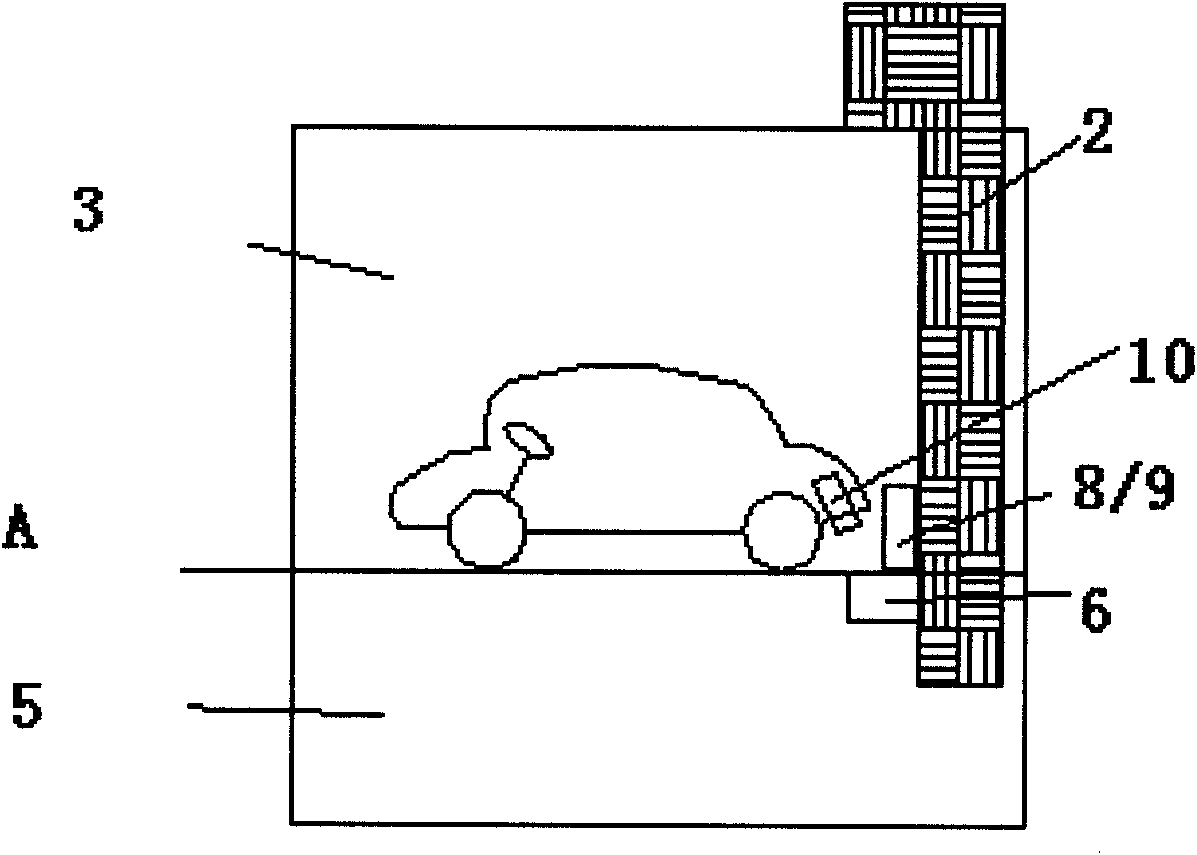

[0027] Such as image 3 In the process of vehicle-related performance testing, a large amount of exhaust gas will be discharged from the exhaust pipe 10 of the vehicle, and the exhaust system will generate negative pressure in the pit, and a large amount of exhaust gas will be discharged through the flap. The design of the soundproof room, and the exhaust exhaust pipe 10 of some models will be discharged to the left and right sides of the chamber. figure 2 new air vents in ).

[0028] Compared with the prior art, the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com