Bookmaking apparatus

A paper stack and component technology, which is applied in book binding, adhesive for binding, transportation and packaging, etc., can solve the problems of increasing the overall size of the device, complex device support structure, and high power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

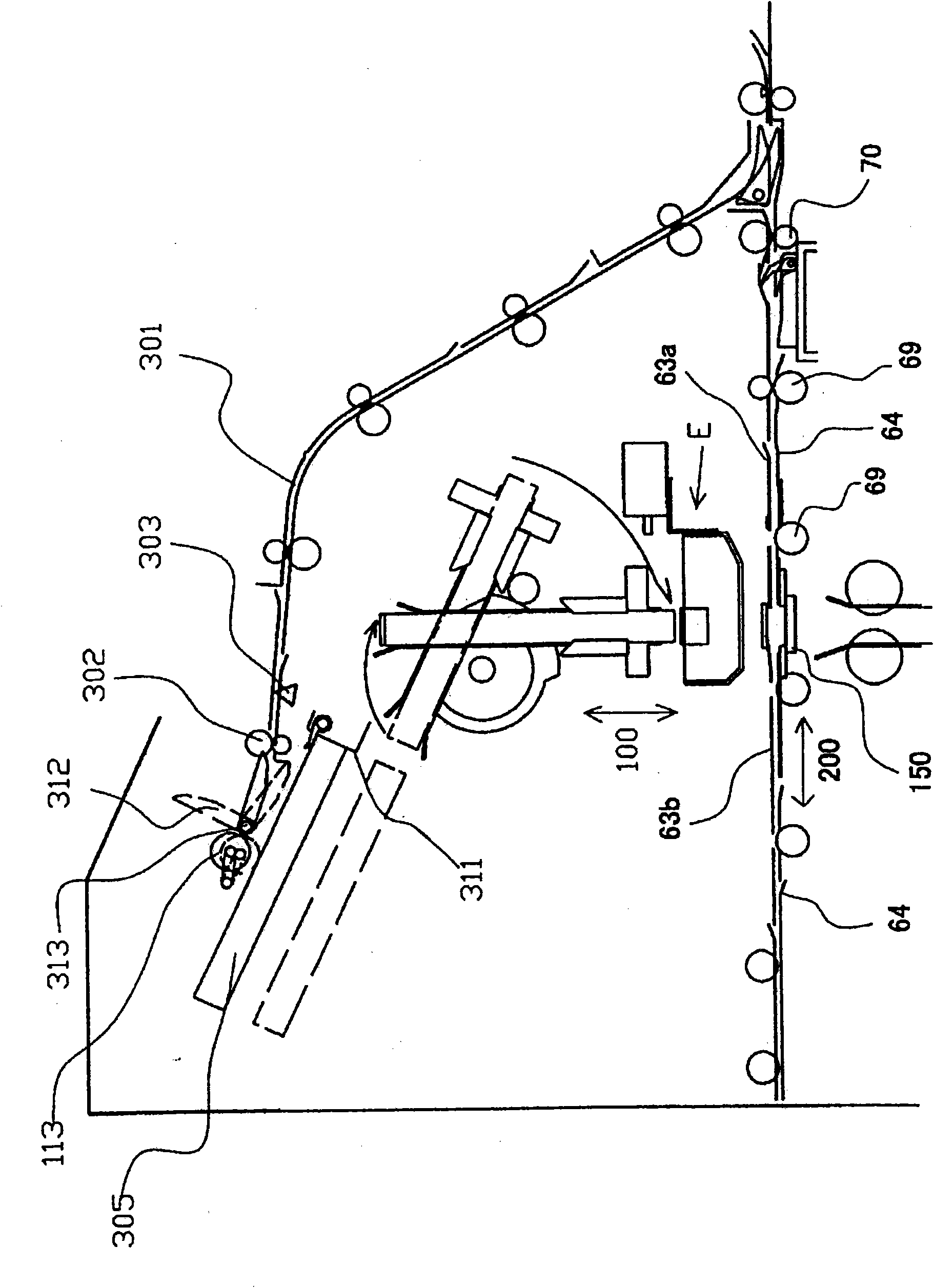

[0102] The present invention will be specifically described below based on the binding device of the present invention shown in the drawings.

[0103] Figure 1A It is an explanatory diagram of the overall structure of the bookbinding system adopting the present invention, Figure 1B An explanatory diagram of its main parts.

[0104] figure 2 is an overall explanatory diagram of the stacked disc assembly, Figure 6 This is an overall explanatory diagram of the stack transport mechanism.

[0105] Figure 19A and 19B is an explanatory diagram of the main parts of the cover transport mechanism, Figure 26A and 26B It is an explanatory diagram of the operation of the paste application unit.

[0106] Figure 1A and 1B The bookbinding system shown is composed of the following parts including an image printing unit A which sequentially prints sheets; Middle; stacking tray assembly C, the stacking tray assembly C loads paper from the image printing assembly A in page order; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com