A kind of manufacturing method of aquaculture anti-escape fence cement pile

A technology of aquaculture and production methods, applied in fish farming, manufacturing tools, climate change adaptation, etc., can solve the problems of rough surface, low cost performance, high cost, etc., and achieve improved lodging resistance, stable and reliable quality, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Aquaculture fence reinforced concrete pile of the present invention is made and adopts the following process steps:

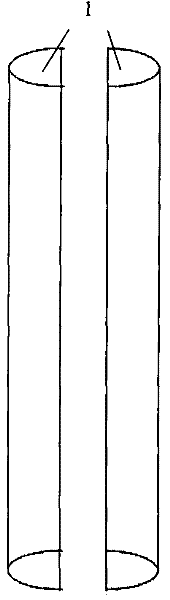

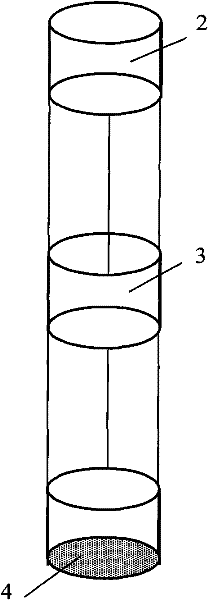

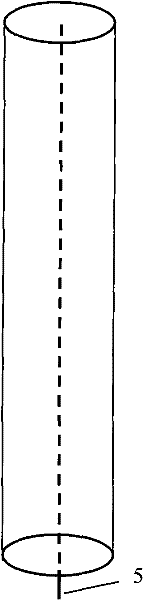

[0023] Such as figure 1 , 2 Shown: the production mold of reinforced cement pile of the present invention is made up of formwork 1, cylindrical upper casing 2, cylindrical middle casing 3 and cylindrical lower casing 4. Such as image 3 Shown: the cement pile that adopts the formwork of the present invention to produce. Such as Figure 4 Shown: the practical application of the reinforced concrete pile produced by the present invention in the fence.

[0024] Templates in the embodiment of the present invention, formwork cylindrical lower end sleeve 4, cylindrical middle sleeve 3 and cylindrical upper end sleeve 2 material selection unplasticized polyvinyl chloride (U-PUC) with a wall thickness of 0.25 cm ) plastic tube, the length of the template is 65 cm, and the diameter is 7.5 cm. It is sawn longitudinally along the diameter to form two semi-arc c...

Embodiment 2

[0027] Aquaculture fence reinforced concrete pile of the present invention is made and adopts the following process steps:

[0028] Formwork in the embodiment of the present invention, formwork cylindrical lower end sleeve pipe, cylindrical middle sleeve pipe and cylindrical upper end sleeve pipe material selection polyvinyl chloride (U-PVC) plastic pipe with a wall thickness of 0.25 cm, the length of the template It is 70 centimeters in diameter and 7.5 centimeters in diameter. It is cut longitudinally along the diameter to form two semi-circular arc columns. The sawn template is polished to reduce the diameter of the overlapped template to 7.4 centimeters; template sleeve The tube has a diameter of 7.5 cm and a length of 12 cm. One side of the cylindrical lower casing 4 is a closed type, the cylindrical middle casing 3 and the cylindrical upper casing are non-closed; the shape of the reinforced concrete pile is cylindrical, the surface is smooth, and the diameter of the stee...

Embodiment 3

[0031] Aquaculture fence reinforced concrete pile of the present invention is made and adopts the following process steps:

[0032] The formwork in the embodiment of the present invention, formwork cylindrical lower end casing 4, cylindrical middle casing 3 and cylindrical upper end casing 2 material selection polyvinyl chloride (U-PUC) plastic pipe with a pipe wall thickness of 0.252 centimeters , the length of the template is 100 cm, and the diameter is 12.5 cm. It is sawn longitudinally along the diameter to form two semi-arc columns. The sawn template is polished to reduce the diameter of the overlapped template to 12.3 cm. ; The template casing has a diameter of 12.5 cm and a length of 12 cm. One side of the cylindrical lower casing 4 is a closed type, the cylindrical middle casing 3 and the cylindrical upper casing 2 are non-closed; the shape of the reinforced concrete pile is cylindrical, the surface is smooth, and the diameter of the steel bar is 0.6 cm , coincides wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com