Method and device for cooling circulating water in turbine condenser

A condenser and circulating water technology, which is applied in steam/steam condensers, lighting and heating equipment, etc., can solve the problem that the circulating water cannot reach the ideal water temperature of the steam turbine condenser, the steam turbine cannot exert the best driving force, and the condensing steam It can reduce the cost of power generation, reduce the number of operations and power, and improve the vacuum degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

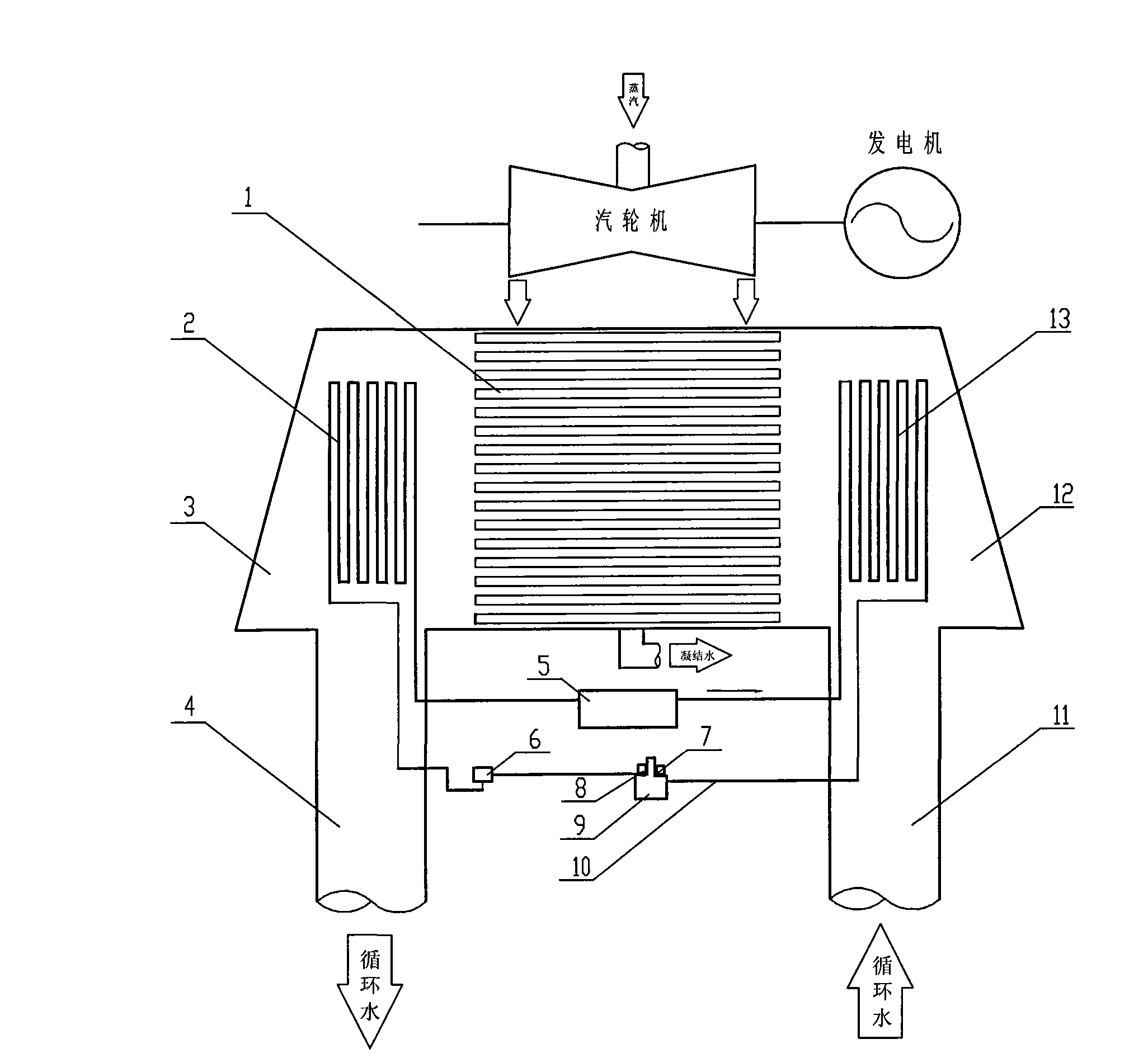

[0021] Please refer to figure 1 , a method and device for cooling circulating water in a steam turbine condenser, mainly composed of a condenser 1 connected to a steam turbine and a refrigerant circulating refrigeration device, characterized in that it is set in the inlet water chamber 12 of the condenser circulating water system The heat-absorbing tubes 13 are installed in the outlet water chamber 3 of the condenser circulating water system; the heat-absorbing tubes 13 and the heat-dissipating tubes 2 are connected by a conduit 10 and a compressor 5 to form a closed circulation pipeline The refrigerant is injected into the pipeline to form a refrigerant cycle refrigeration device; the heat-absorbing tubes 13 of the refrigerant cycle refrigeration device perform rapid cooling on the circulating water in the inlet water chamber 12 of the condenser circulating water system, and the refrigerant cycle refrigeration device The cooling tubes 2 use the circulating water in the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com