Single-screw meshing mechanism with reducing generatrix two-time enveloping single-screw meshing molded line

A technology of secondary enveloping and meshing mechanism, applied in mechanical equipment, machine/engine, liquid fuel engine, etc., can solve problems such as leakage, and achieve the effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0026] The present invention is illustrated below:

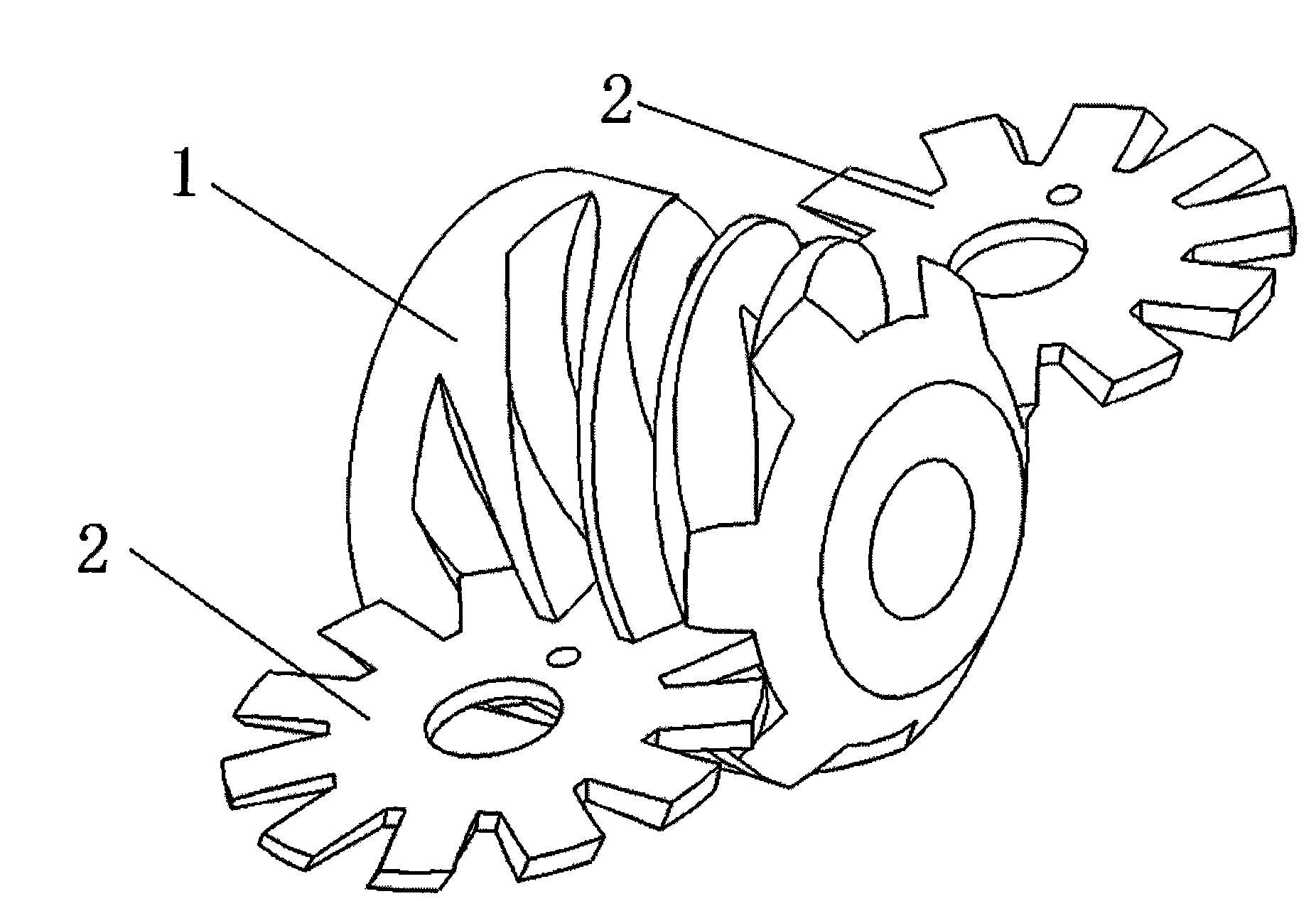

[0027] Screw 1 outer diameter d 1 =230mm, outer diameter of star wheel 2 d 2 = d 1 =230mm, the distance between the centerline of the screw 1 and the centerline of the star wheel 2 A=184mm, the tooth depth of the star wheel or the depth of the screw groove e=0.2d 1 =0.2×230=46mm, screw groove width B=34.5mm (see figure 1 ).

[0028] When the center position of the star wheel is h=3mm higher than the center position of the screw, the design and calculation of the double-enveloping single-screw meshing profile of the variable diameter female surface are as follows:

[0029] 1. Determination of parameters r, R, γ of variable diameter generatrix (see image 3 ).

[0030] small end diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com