Gas end surface sealing structure with three-dimensional feather-like textured bottom shaped grooves

A three-dimensional technology of end face sealing, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems that the end face air film opening ability cannot adapt, the dynamic pressure effect is not strong enough, the pressure resistance is not strong, etc., to achieve enhanced pump The pumping effect and the end surface lubrication effect are beneficial to the fluid entering the end surface and the effect of improving the static pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

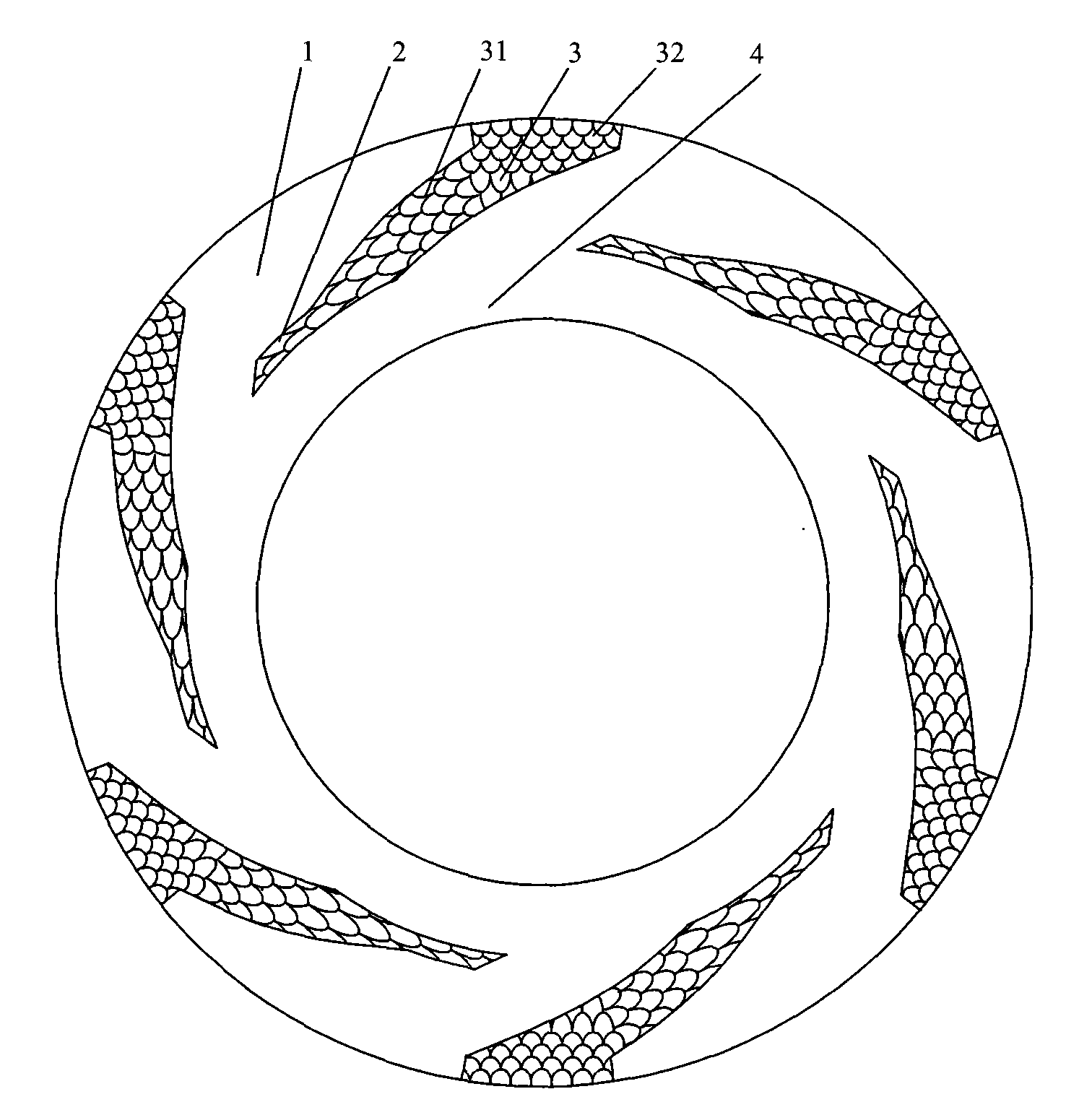

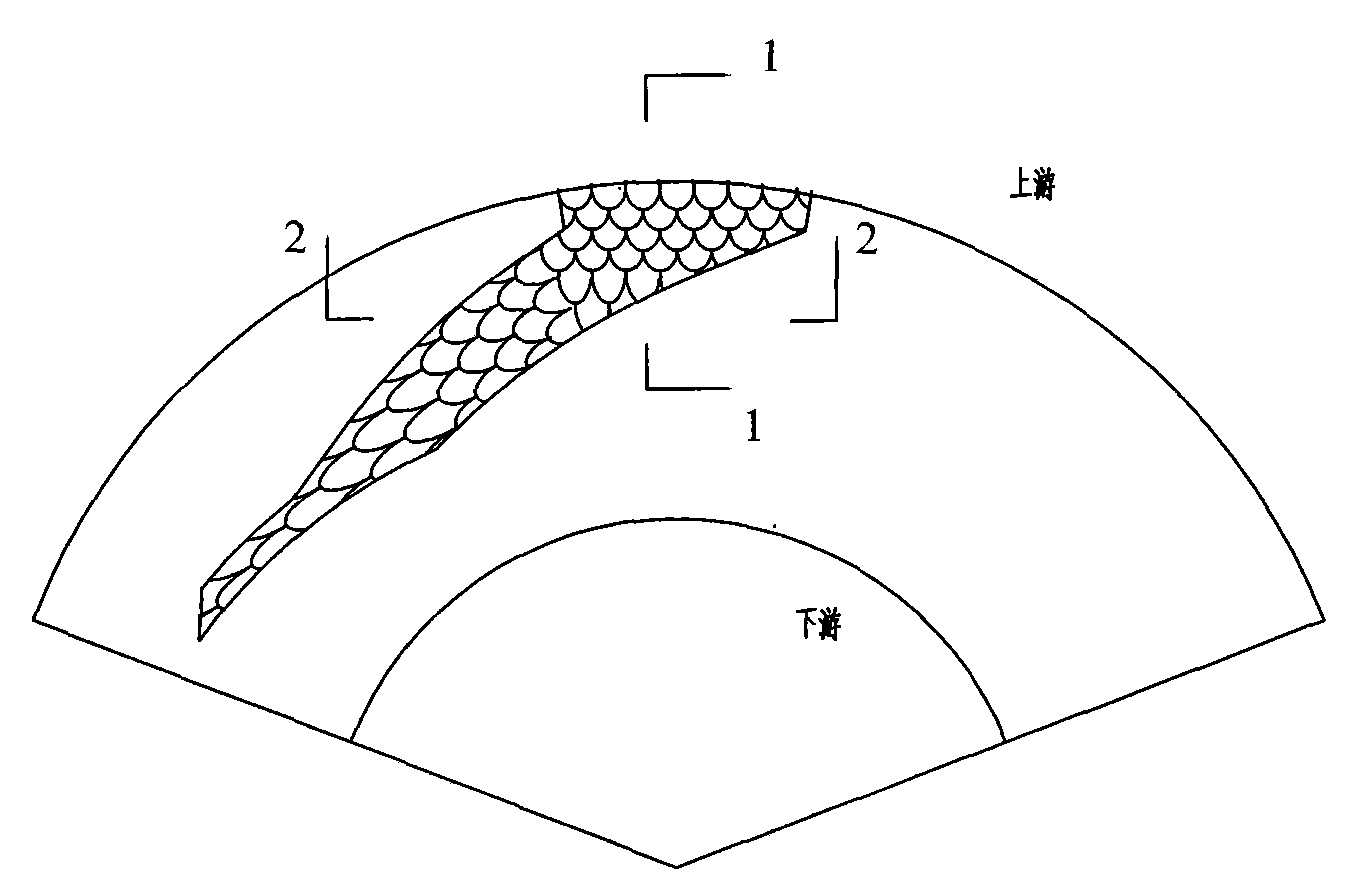

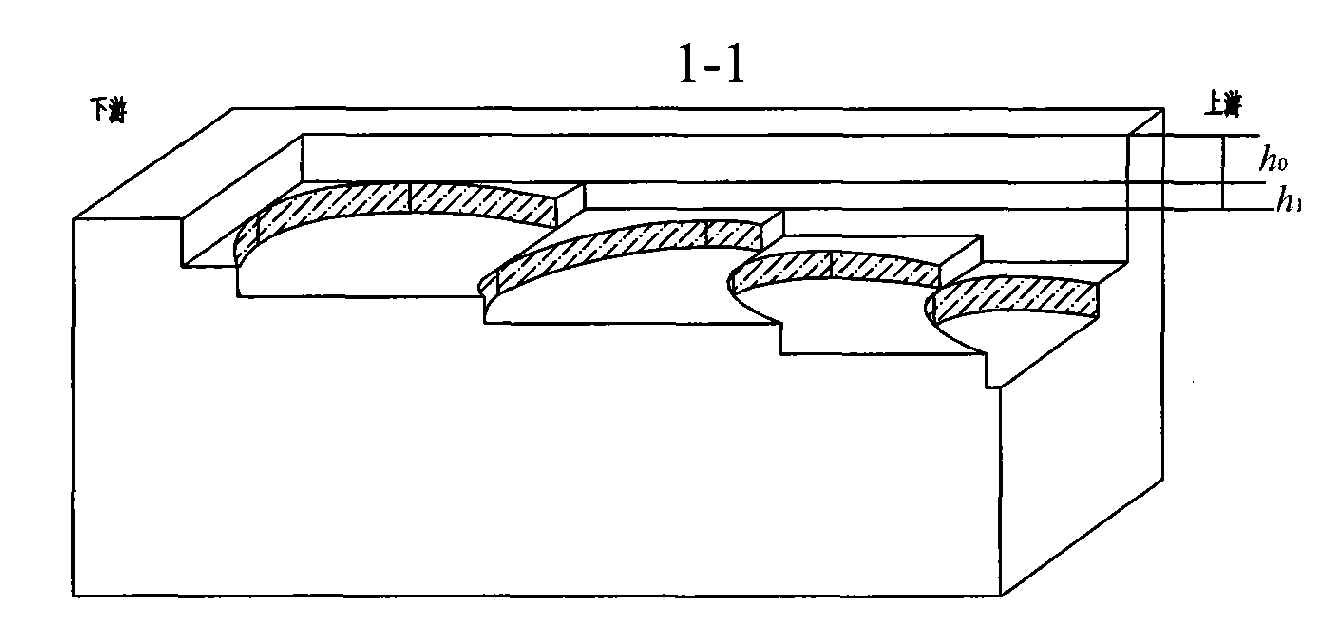

[0027] Reference Figure 1-4 , A three-dimensional feather-like texture bottom surface groove gas end surface sealing structure, including a mechanical end surface seal of a moving ring, a static ring and other related parts. The sealing end surface of the moving ring and the sealing end surface of the static ring are attached to each other to form a circle Annular seal end face, one side of the annular seal end face is the high pressure side, that is, upstream, and the other side of the annular seal end face is the low pressure side, that is, downstream. When rotating, at least one of the sealing end surfaces of the moving ring and the static ring is provided with a plurality of three-dimensional grooves 3 for gas end surface sealing, and the three-dimensional grooves are periodically arranged on the sealing end surface along the ring surface. Distributed symmetrically in the center, the non-slotted area between the three-dimensional grooves constitutes the sealing weir 1. The...

Embodiment 2

[0036] Reference Image 6 The difference between this embodiment and the first embodiment is that the structural dimensions of the spiral groove 31 and the pumping groove 32 are different. The long spiral groove three-dimensional groove and the short spiral groove three-dimensional groove are along the end surface The circumferential direction is distributed periodically, and the groove length and dam length of the short spiral groove three-dimensional groove are larger than l 4 / l 5 The range of values is: l 4 / l 5 =0.8~1.5, the groove shape is shorter and wider, and the groove tail resembles feather texture staggered arrangement; the length ratio of the groove length to the dam length of the long spiral groove three-dimensional groove is l 4 / l 5 The range of values is: l 4 / l 5 =1.5~4.5, the groove shape is relatively narrow, long and flat, and the groove tails are arranged like feather texture parts overlapping; the radial length of the two sides of the pumping groove is d...

Embodiment 3

[0038] Reference Figure 7 , Figure 8 The difference between this embodiment and the first embodiment is that the spiral groove 31 is a bidirectional groove symmetrically distributed along the connection point of the spiral groove 31 with the pumping groove 32. The shape of the spiral groove 31 may be a bird-like wing shape, a crescent shape, a chevron shape, or an iron anchor shape to meet the requirements of bidirectional rotation. The rest of the structure and implementation are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com