Ionized current superfine foam generating device and ionized current superfine foam generating method using device

A generation device and fine technology, applied in flotation water/sewage treatment, etc., can solve problems such as increased maintenance costs, increased drug consumption, and high manufacturing costs, and achieve the effect of improving response capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

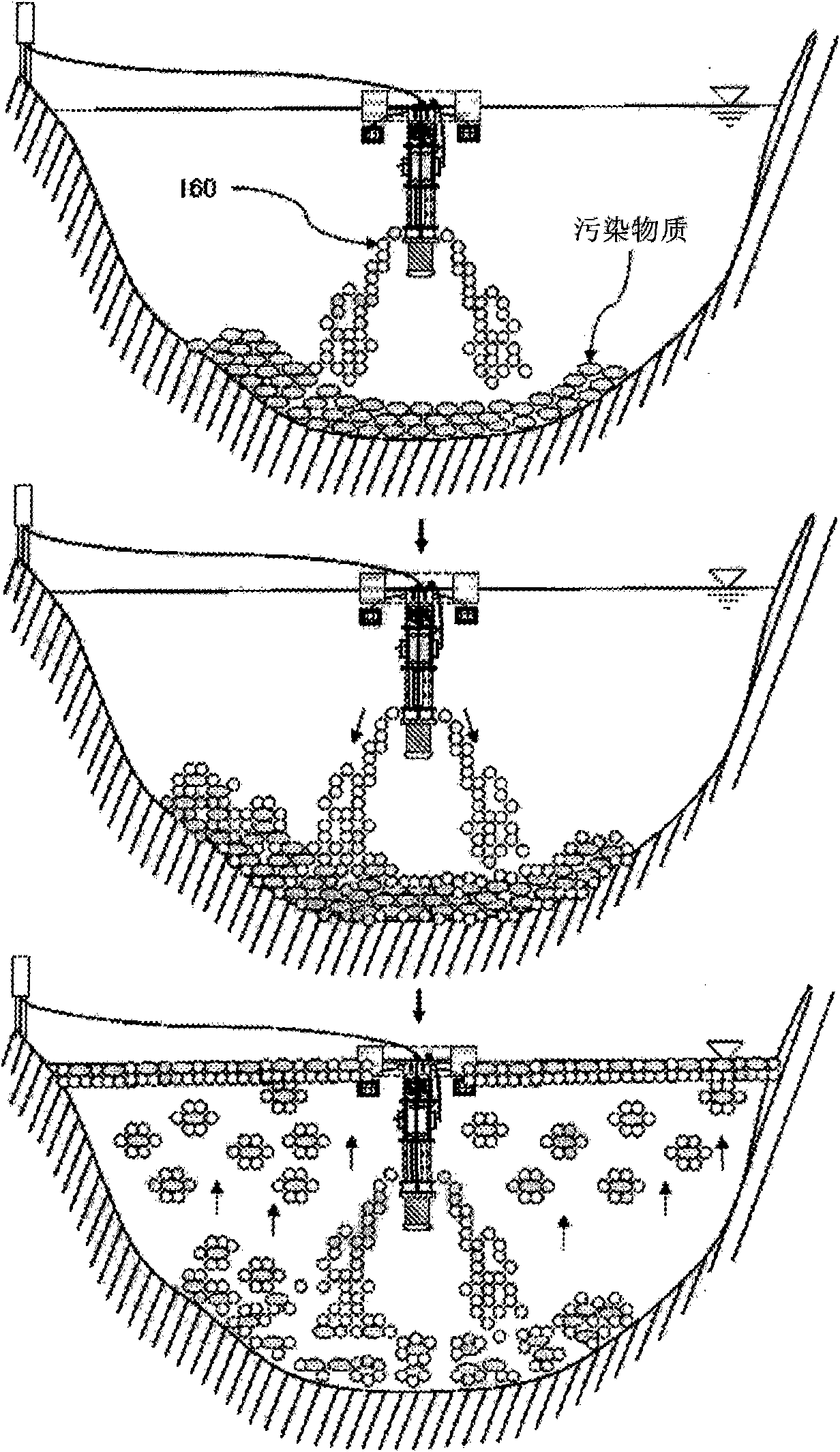

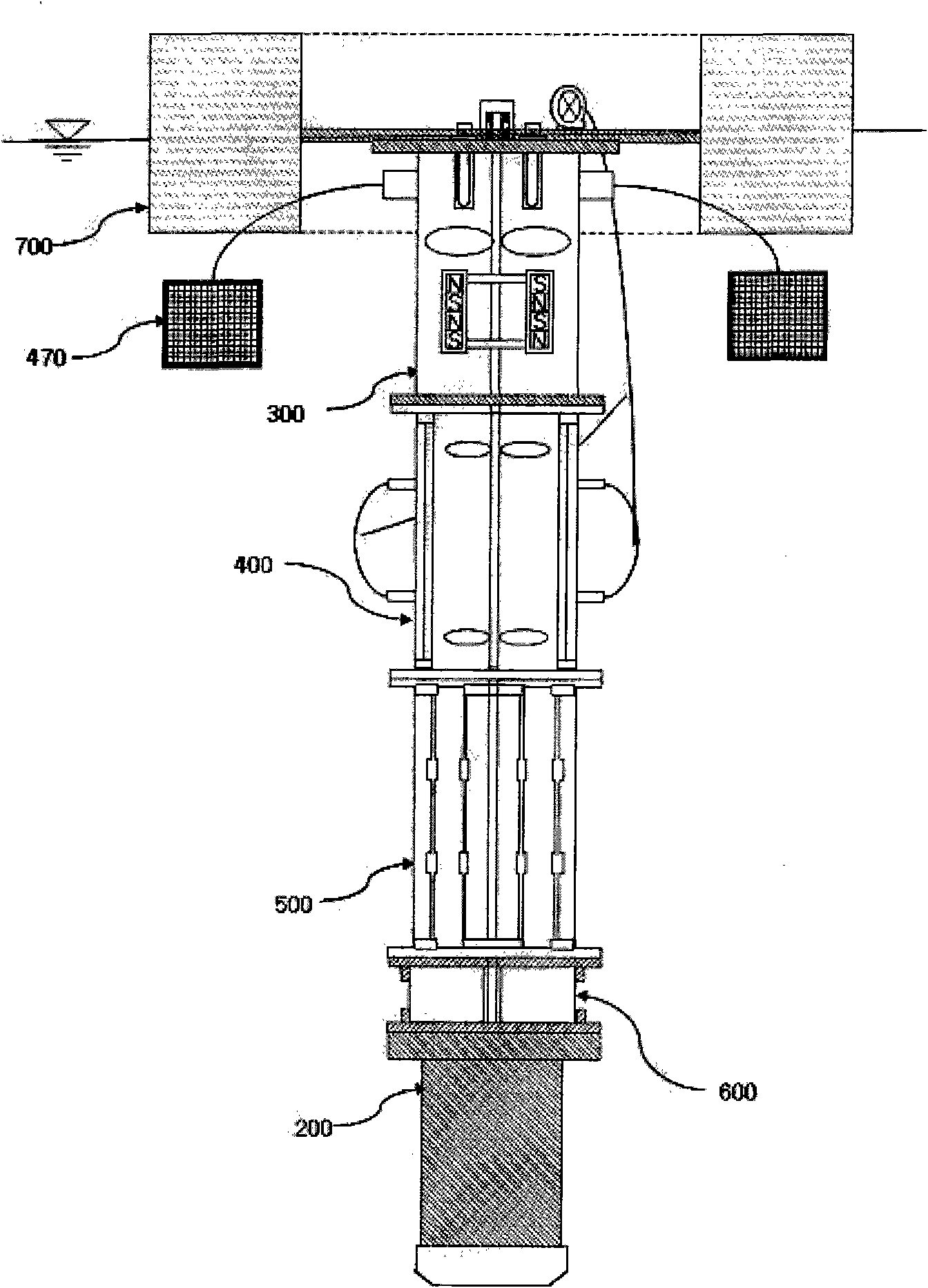

[0035] figure 1 It is a schematic diagram of an embodiment of the ionic water flow fine foam generating device of the present invention installed in the treatment water area and the purification treatment process of polluted water.

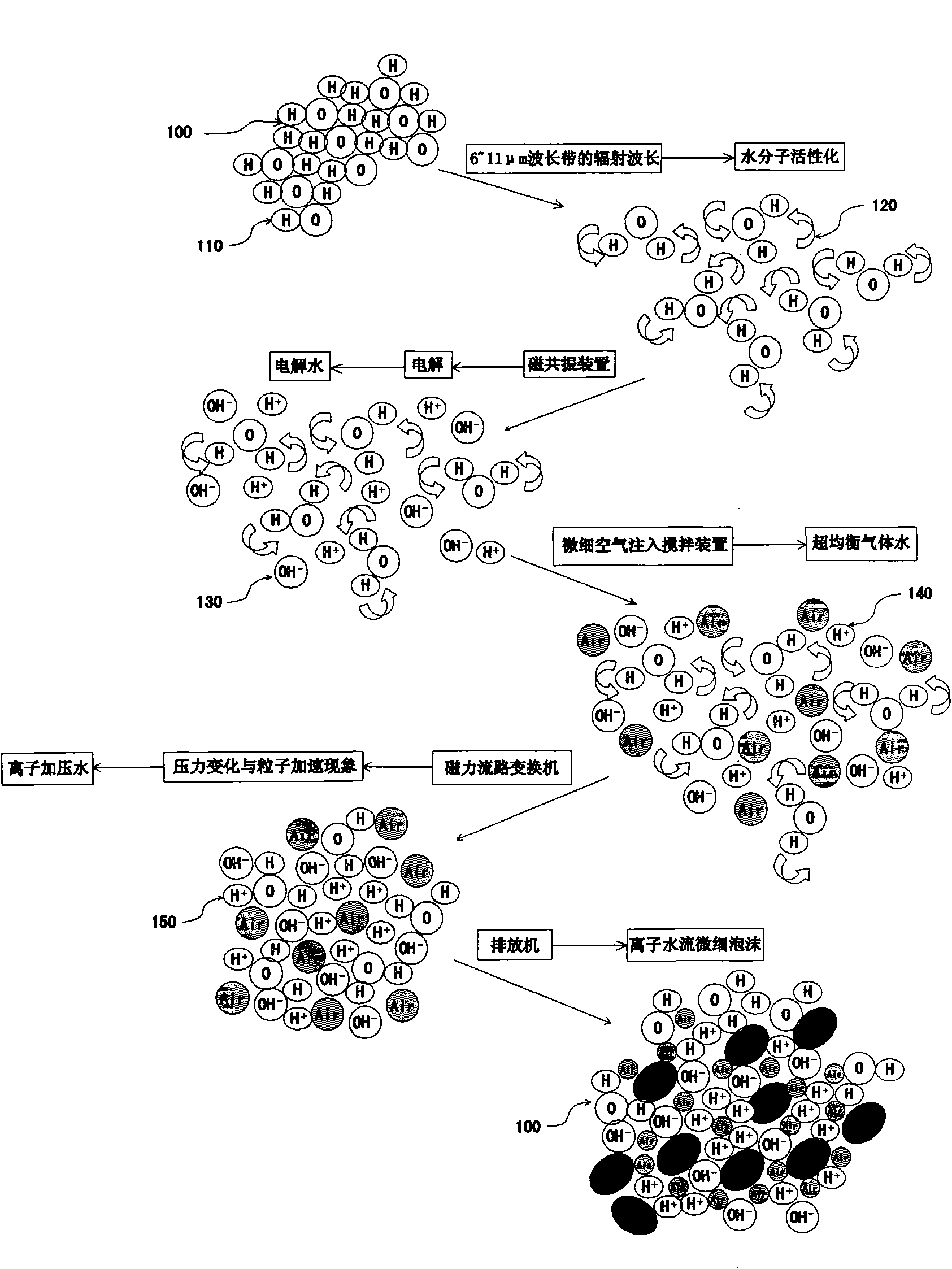

[0036] As shown in the figure, the ionic water flow fine foam generating device is installed in water through a floating machine to generate ionic water flow fine foam 160. The above-mentioned ionic water flow fine foam 160 is electrolyzed without electrodes under the influence of the radiation wavelength projected by the far-infrared lamp Work and form a viscous foam, and then become a state containing active material ions, the increased hydrophilicity will form the MHD phenomenon (magnetohydrodynamic, superconducting phenomenon), and the foam or OH group around the H will cause surface tension, so the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com