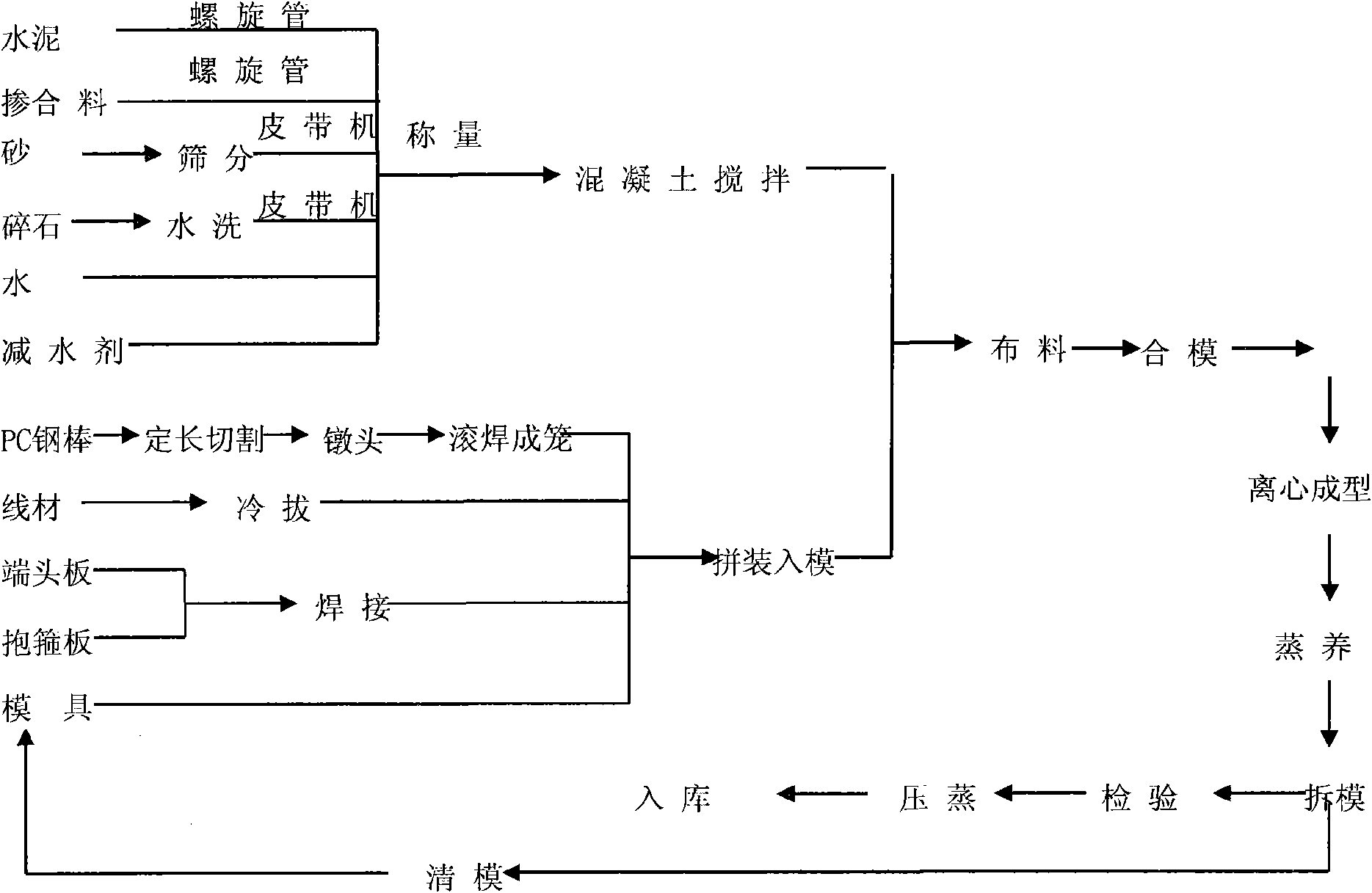

Production process of short tubular piles

A production process and short tube technology, which is applied in the field of prestressed high-strength concrete pipe pile production technology, can solve the problems of lack of pipe pile production technology, and achieve the effect of low production cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

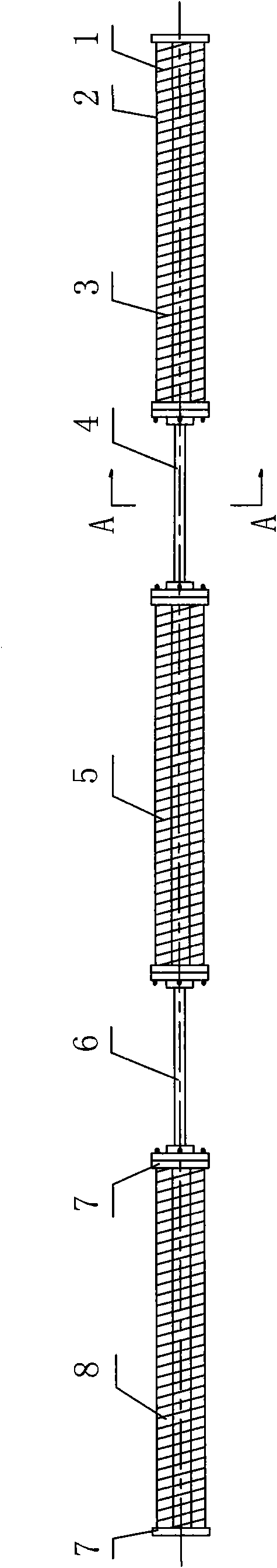

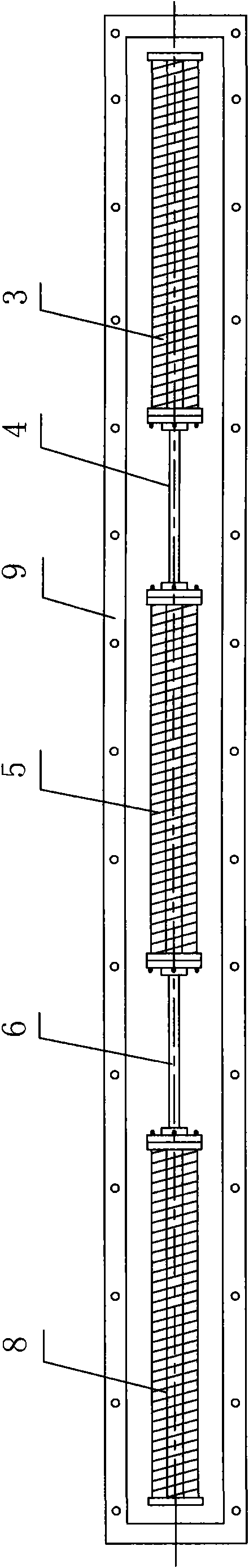

[0030] The production technology of short pipe pile (two meters long, the pipe pile of diameter 300mm), it comprises the following steps:

[0031] 1) Prepare high-performance concrete (using existing known technology): high-performance concrete includes cement, admixtures, coarse aggregate (such as gravel), fine aggregate (such as sand), and water reducing agent (high-efficiency water reducing agent) and water; use PO52.5 cement 420kg, admixture 80kg, water 160kg, crushed stone 1093kg, sand 750kg, water reducer 27kg for each cubic meter of concrete; select various raw materials; cement, admixture, coarse aggregate, fine Aggregate, water reducing agent and water are mixed and stirred to obtain high-performance concrete. The admixture is Class II fly ash, and Class II fly ash that meets the requirements of the national standard can be used. The function of the water reducer is to reduce the amount of water without affecting the workability of the concrete and increase the streng...

Embodiment 2

[0042] It is basically the same as Example 1, except that the high-performance concrete adopts other existing known compositions and proportions (that is, the existing high-performance concrete is applicable to the present invention).

Embodiment 3

[0044] It is basically the same as embodiment 1, and the difference is that the 2-meter-long reinforcement cage is changed into a 1-meter-long reinforcement cage, and the mold is selected from an existing 15-meter-long mold; 8 1-meter-long reinforcement cages with pile heads are made of 7 connecting devices are connected into one; finally, 8 sections of 1-meter-long short pipe piles are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com