Demister used for dust-removing desulfurization tower

A technology of mist eliminators and desulfurization towers, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as fog running out, and achieve the effect of increasing the moving distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

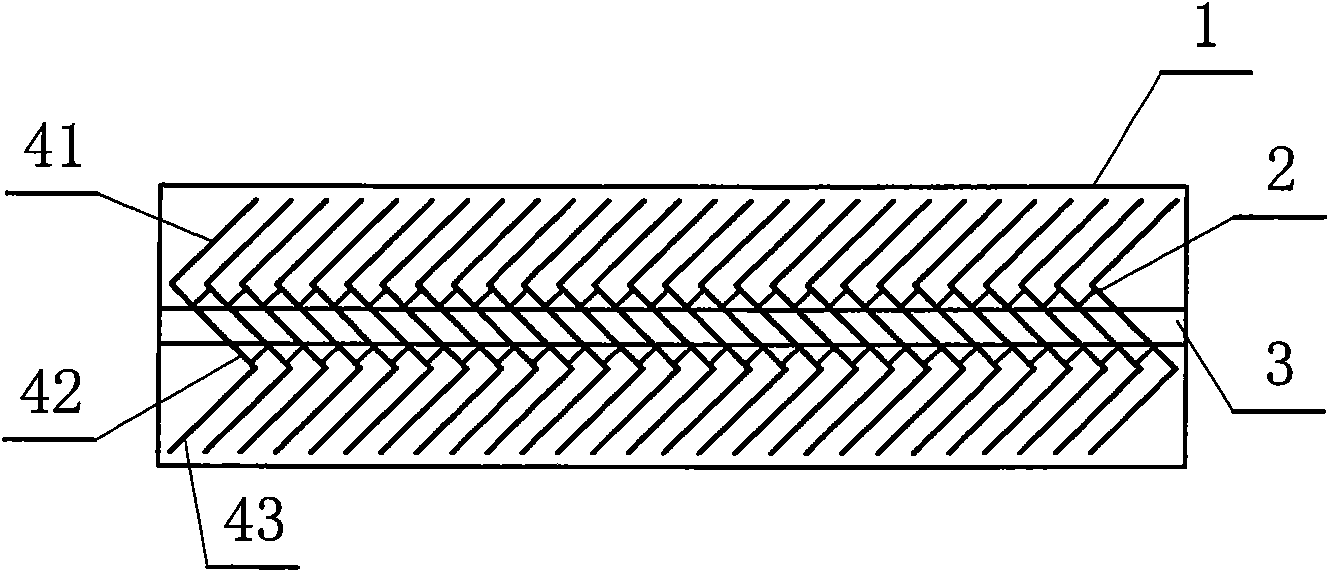

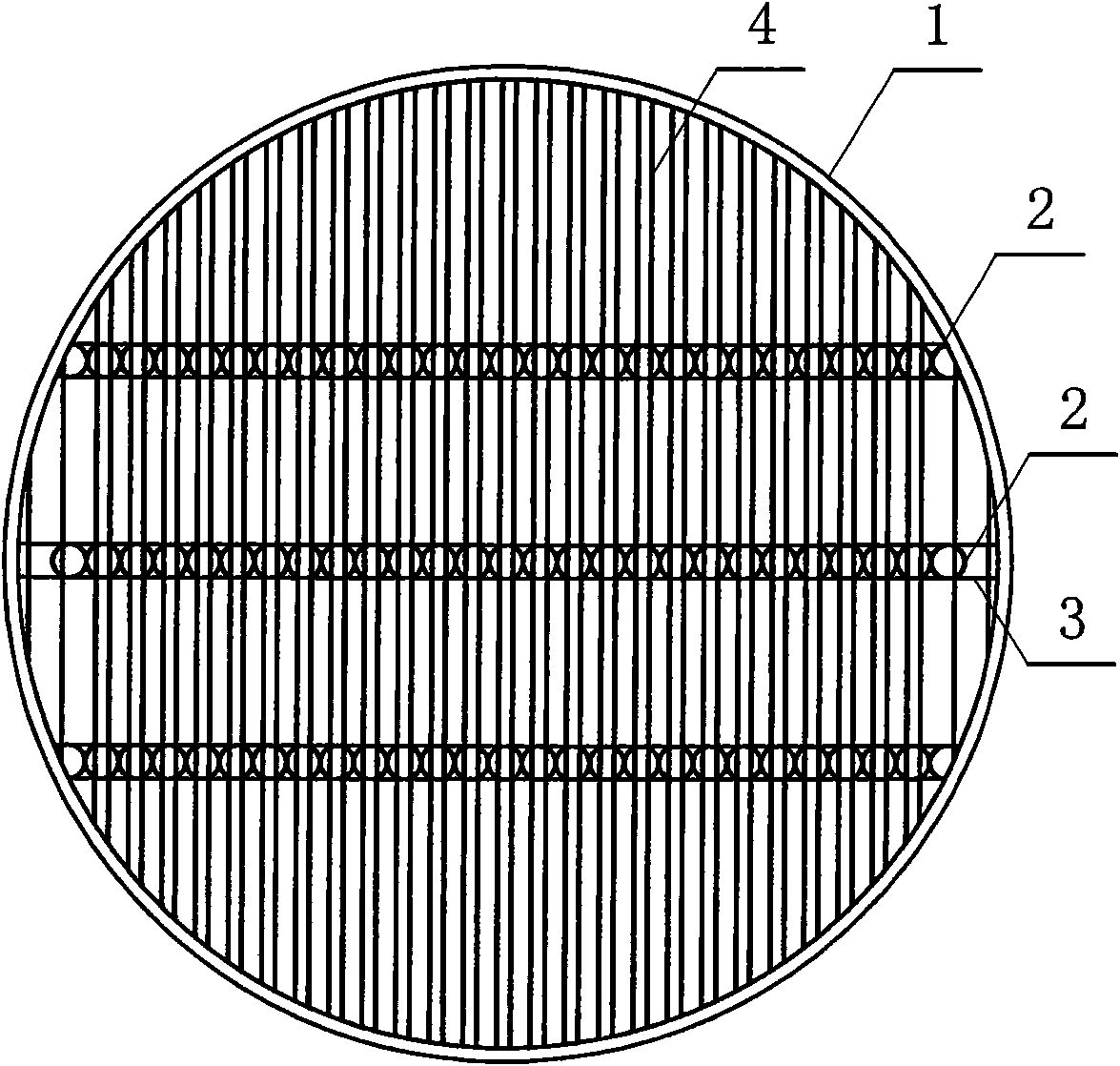

[0013] refer to figure 1 , figure 2 It is an embodiment of the mist eliminator for dust removal and desulfurization towers of the present invention. The mist eliminator for dust removal and desulfurization towers includes an annular frame 1, at least one clip 2, at least one fixing rod 3 and at least one bent defogger plate 4. The defogging plate 4 is set in the circular frame 1, and a clip 2 is set between every two defogging plates 4, and the clip 2 is set on the fixing rod 3, and the fixing rod 3 wears The defogging plate 4 is provided, and the two ends of the fixed rod 3 are arranged inside the frame 1. The defogging plate 4 is spliced into an S shape by three straight plates, the upper plate 41, the middle plate 42, and the lower plate 43. The upper plate 41 forms an included angle of 45 degrees with the horizontal plane, a negative 90-degree included angle is formed between the middle plate 42 and the upper plate 41, a 90-degree included angle is formed between the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com