Winding type electric reactor

A reactor, winding technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problems of affecting the heat dissipation effect, small heat dissipation air channel area, waste of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

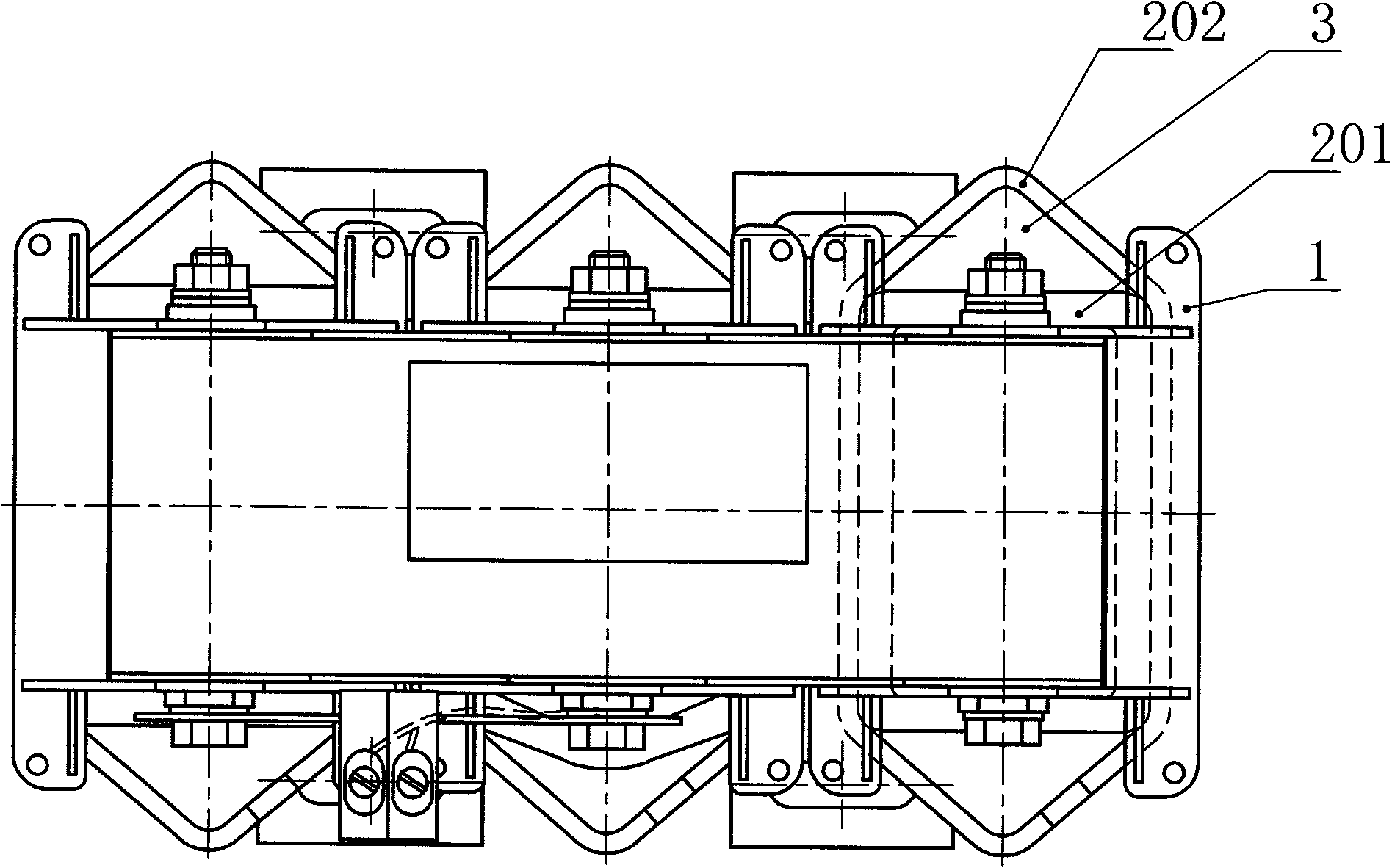

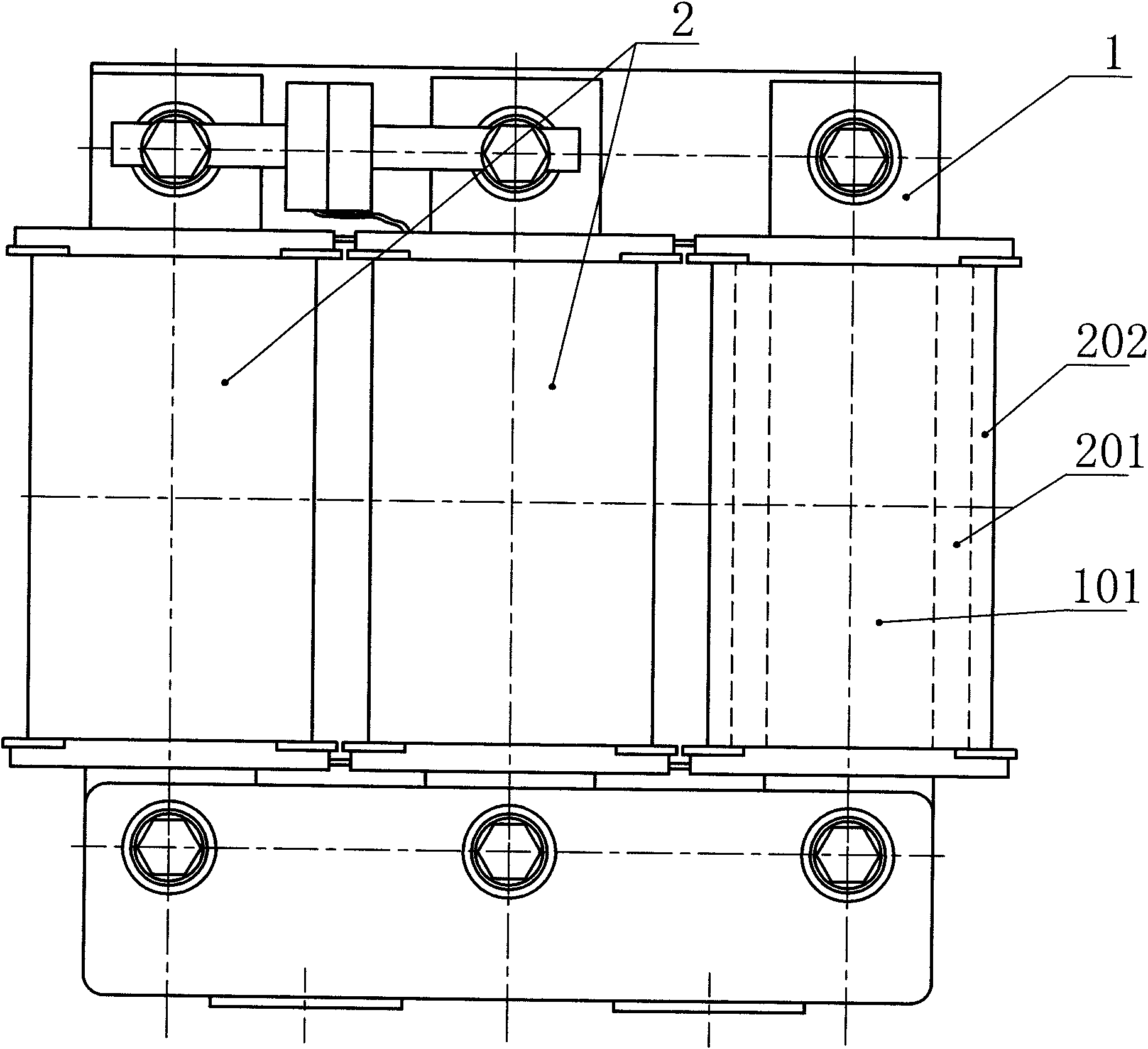

[0009] Such as figure 1 and 2 , a wire-wound reactor, including a skeleton 1 connected by an upper iron yoke, a lower iron yoke, a core column and a pull plate. On the skeleton 1, a coil 2 is wound outside the core column 101. The coil 2 consists of an inner layer coil 201 and an outer The layer coil 202 is composed of two sides of the outer layer coil 202 and the inner layer coil 201 are arranged in a triangle shape, and a triangular heat dissipation air passage 3 is respectively left between the outer layer coil 202 and the inner layer coil 201 on both sides. The coil 2 in the figure is a three-phase coil, correspondingly, the core column 101 , the outer coil 202 and the inner coil 201 form three groups.

[0010] When winding, a triangular support is used to clamp between the two sides of the outer coil 202 and the inner coil 201. After the winding is completed, the support is pulled out, so that the heat dissipation air passage 3 is triangular, because the triangle is a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com