Supply pipeline of developing solution

A developer and supply tube technology, which is applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of crystal blockage, defectiveness, and reduced development of the developer nozzle, and achieve the effect of avoiding insufficient developing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be described in more detail below in conjunction with the accompanying drawings.

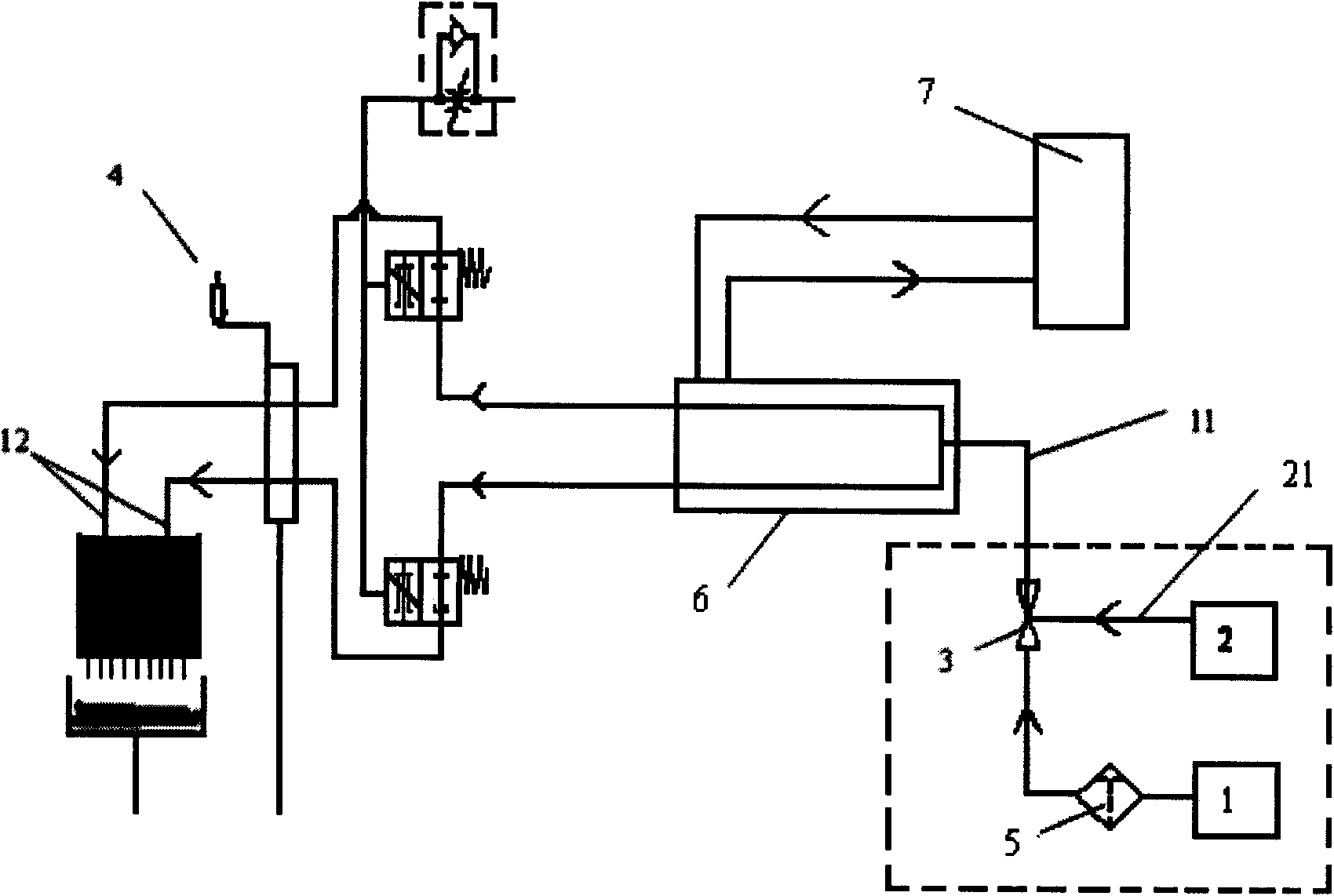

[0016] see figure 2 , a developer supply pipeline, comprising a developer pipeline 11, a developer nozzle 12 positioned at the front end of the developer pipeline, and a deionized water pipeline 21 connected in parallel with the developer pipeline, the deionized water pipeline 21 passing through The control valve 3 installed to the developer pipeline is connected to the developer pipeline 11 . The developer pipeline generally has a buffer tank (Buffer tank, used for temporary storage of the developer), a Teflon pipeline, a filter (Filter, used for filtering the developer), and a fan (Fan flow, used for flow detection) , pneumatic valve (for controlling the switch of developing solution spraying), constant temperature exchange system 6, temperature monitor 7, nozzle 12 (for spraying developing solution onto the wafer surface) and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com