High purity biomass gas preparation heat supply and gas storage device

A biomass, high-purity technology, applied in the manufacture of combustible gas, petroleum industry, combined combustion mitigation, etc., can solve the problems of unreasonable structure, low heat utilization rate, low gas purity, etc., achieve reasonable structure, high thermal efficiency, reduce Effects of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

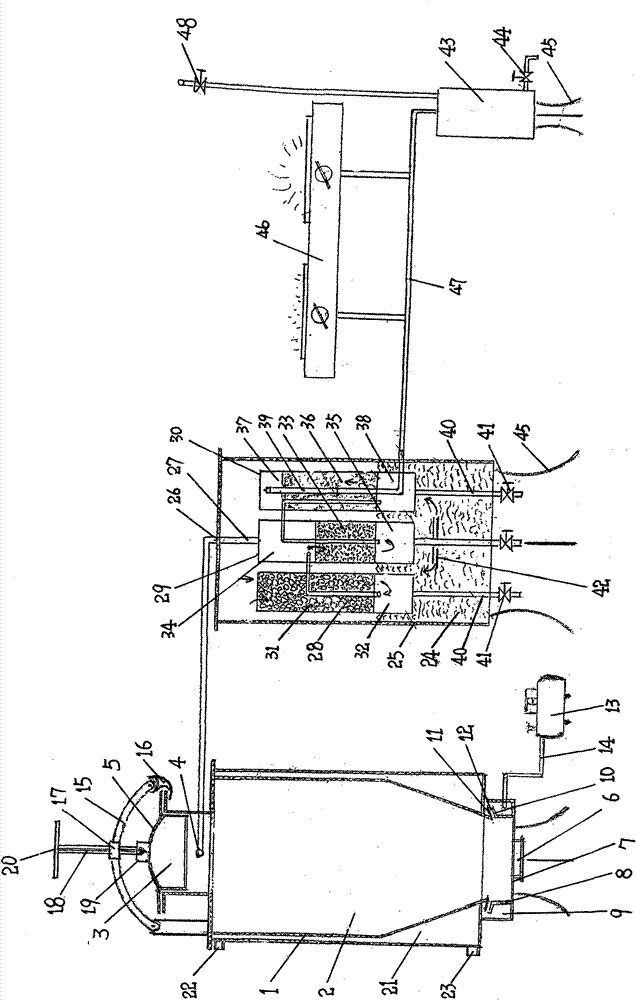

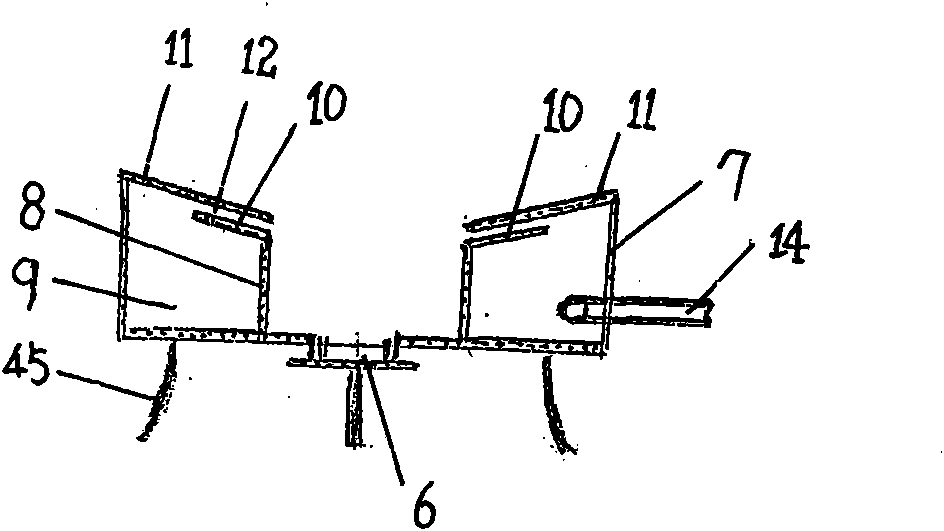

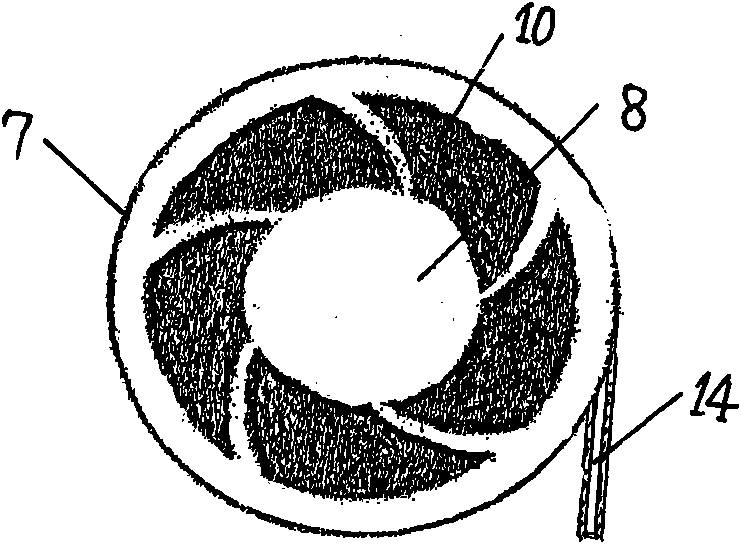

[0016] Such as figure 1 As shown, a high-purity biomass gas production, heating, and gas storage equipment includes a gas production device and a gas purification device. The gas production device includes a furnace body 1, a gasification chamber 2 is provided in the furnace body, and the outer wall of the furnace body 1 and gas A water cavity 21 is provided between the chemical chambers 2. A heating water outlet 22 and a heating water return 23 communicating with the water cavity are respectively opened on the furnace body and below the furnace body. The top of the furnace body is provided with a feed in communication with the gasification chamber 2 Port 3 and gas outlet 4, the feed port 3 is provided with a sealing cover 5, and the sealing cover 5 is provided with a tightening member. The tightening member includes a tightening ring 15 hinged to the furnace body 1 at one end, and the other end of the tightening ring There is a hook 16 for pressing the sealing cover 5 and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com