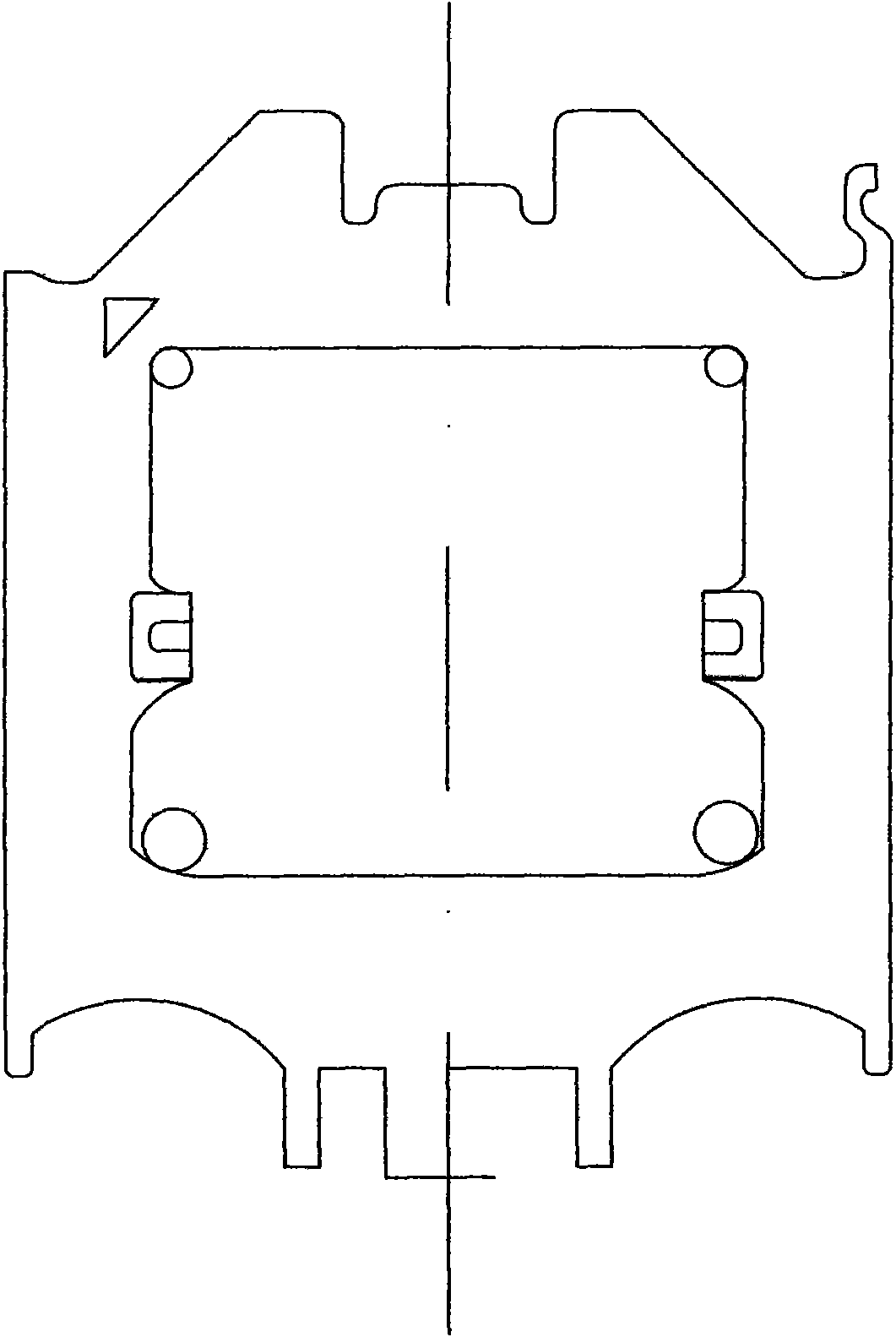

Novel mould material in-frame four-point positioner

A point positioning and mold technology, which is applied in the field of four-point positioning mold strips, can solve problems such as the inability to meet the needs of strip positioning, and achieve the effect of reducing development investment costs, meeting product stamping requirements, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] This specific embodiment adopts the following technical solutions: it includes a stainless steel module 1, which also includes a four-point positioning 2, and the four-point positioning 2 is arranged inside the stainless steel module 1; the four-point positioning 2 is arranged in the inner frame of the stainless steel module 1 Four-point positioning, breaking through the traditional two-point positioning; it can meet the needs of material strip positioning, and can at least reduce the width of the material by 30%-40%, which greatly reduces the cost of material use, and can meet the stamping requirements of the product. At the same time, it can Reduce the length of the mold by 10%-15%, and reduce the development input cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com