Pipeline cleaning method

A pipeline flushing and pipeline technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of low cleanliness and long time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

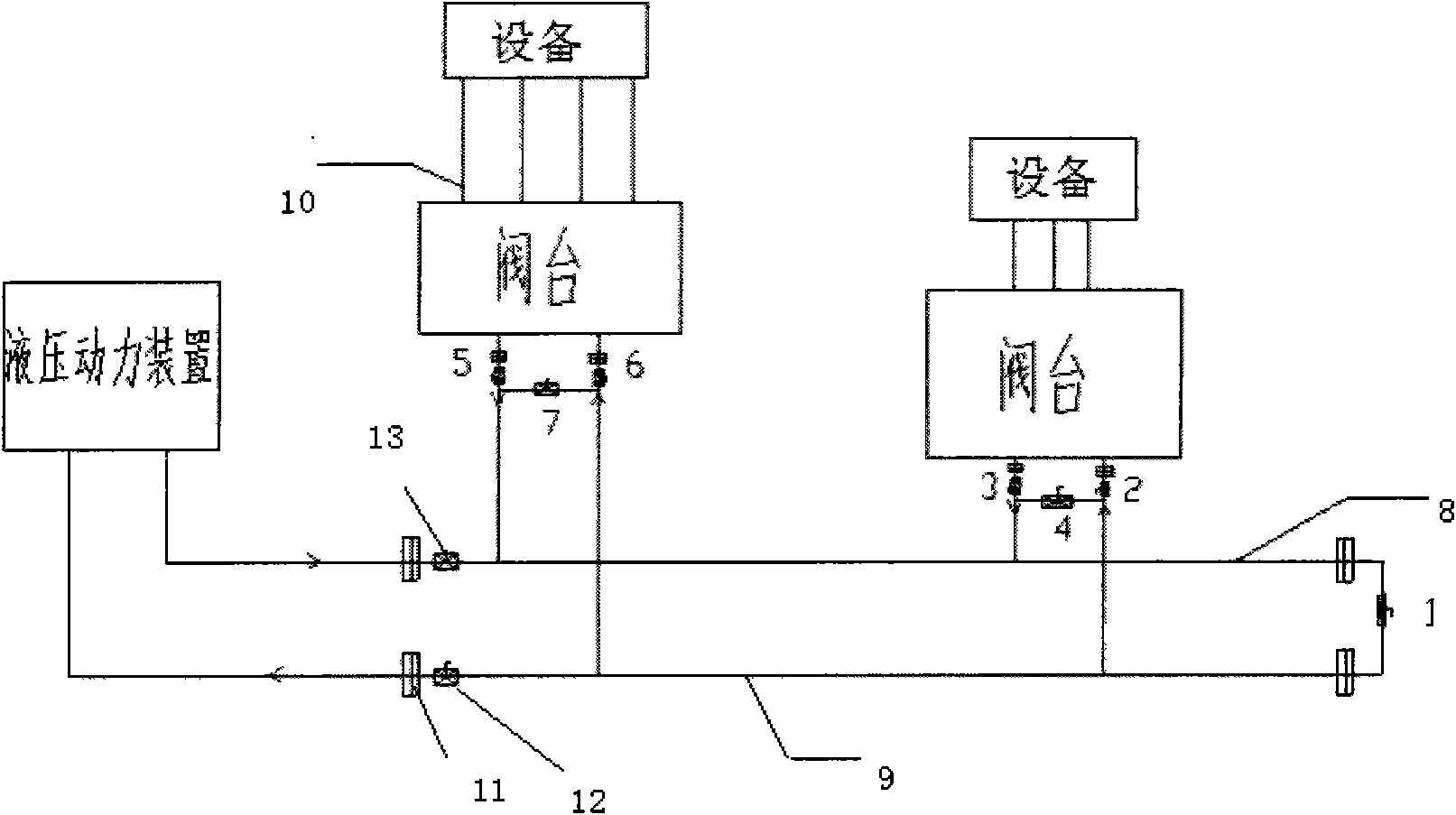

[0019] In order to illustrate the above-mentioned pipeline cleaning method more clearly, it is described in further detail below in conjunction with the accompanying drawings:

[0020] figure 1 It is a structural schematic diagram showing the cleaning device used in the pipe cleaning method according to the present invention. Such as figure 1 As shown, the hydraulic device in the embodiment is mainly composed of hydraulic power device, valve table, equipment and other devices, and the various devices are connected through the oil return pipeline 8, the oil supply pipeline 9, and various branch pipelines and short pipelines. It can be connected by socket welding or high-diameter flange bolts without using threaded fittings to ensure the cleanliness between pipes, such as figure 1 As shown, bypass valves 1, 2, 3, 4, 5, 6, and 7 are respectively installed between each pipeline, and when the valve is closed, it plays the role of isolating the valve and can block the entry of flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com