Sieve mesh with adjustable sieve pore gaps

A technology of gaps and sieve holes, which is applied in the direction of sieving, solid separation, grille, etc., can solve the problems of increasing economic burden, low screening efficiency, and low screening precision, so as to reduce economic burden, reduce economic expenditure, and screen The effect of high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

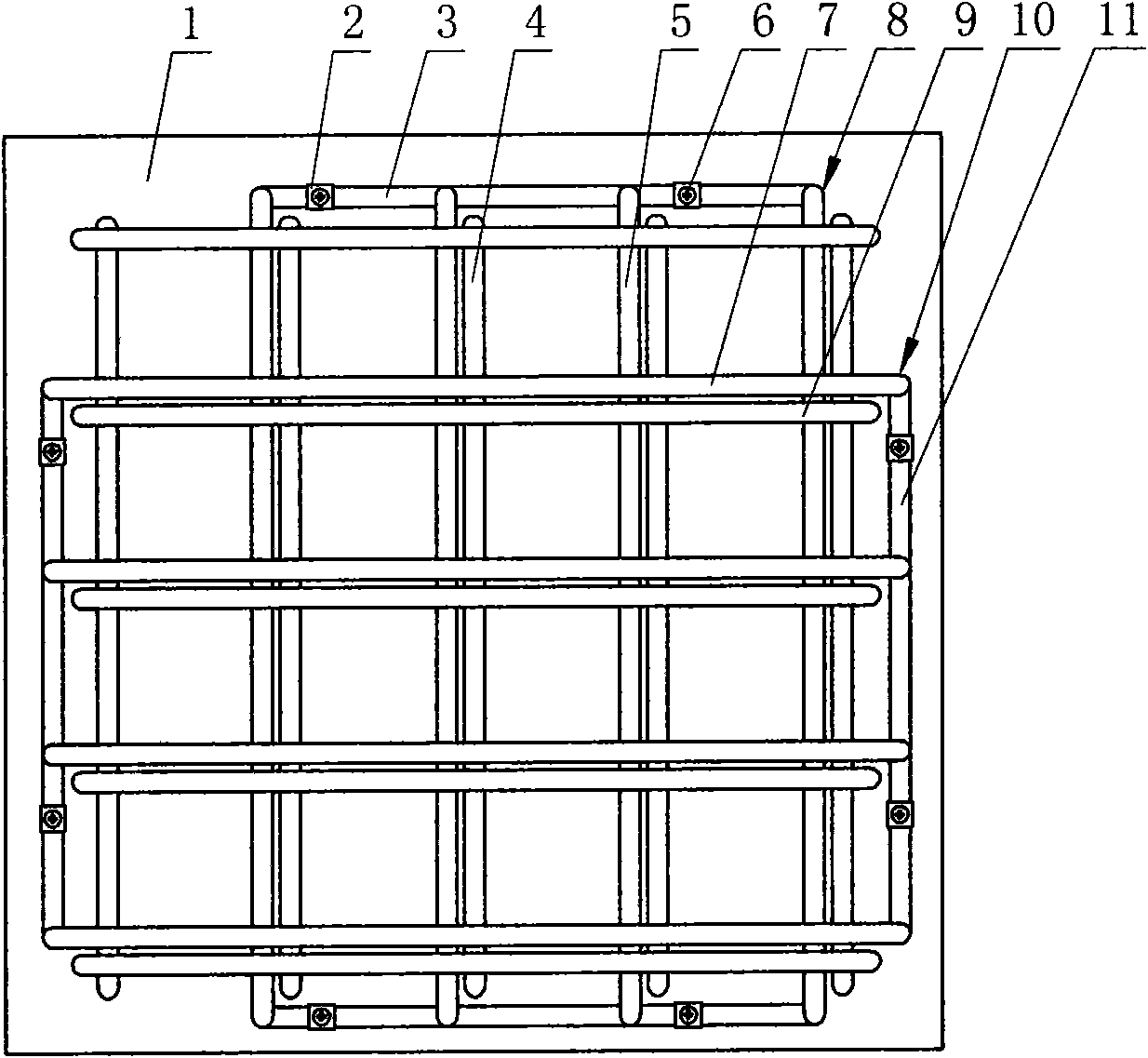

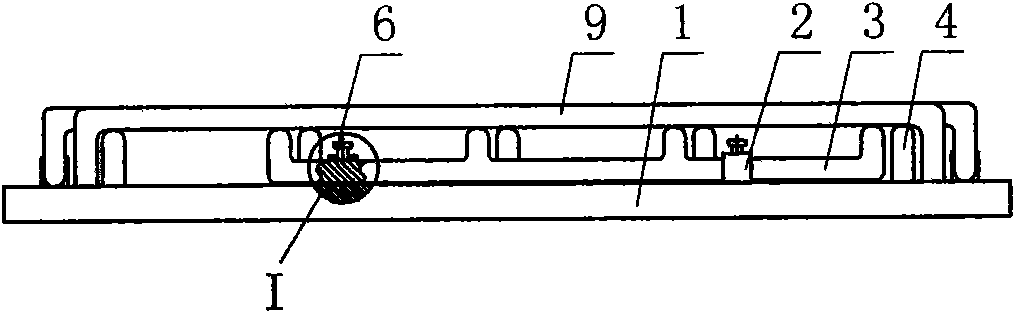

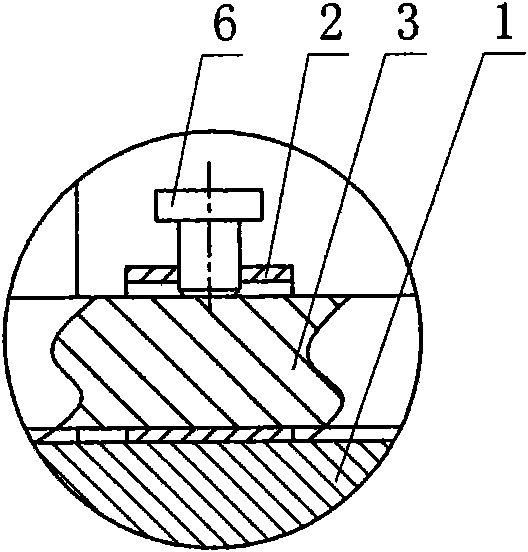

[0026] A sieve cloth with adjustable clearance between sieve holes is composed of a frame 1, cross bars 9 and longitudinal bars 4, and the cross bars and longitudinal bars are evenly distributed and interlacedly installed on the frame to form sieve holes.

[0027] The innovation of the present invention is that: a group of movable frames 8 moving along the X axis and a group of movable frames 10 moving along the Y axis are arranged on the frame, and the movable frames moving along the X axis and the movable frames moving along the Y axis are both 1 to 10. figure 1 and Figure 5 Schematic diagrams for one group and two groups of active frames are shown respectively.

[0028] The upper beams 5 uniformly distributed by each movable frame movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com