Sidewalk ground tile paving die

A technology for sidewalks and floor tiles, which is applied in the field of municipal equipment, can solve the problems of floor tiles activities, low work efficiency, and different amounts of fine sand, and achieve the effect of not easy loosening and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

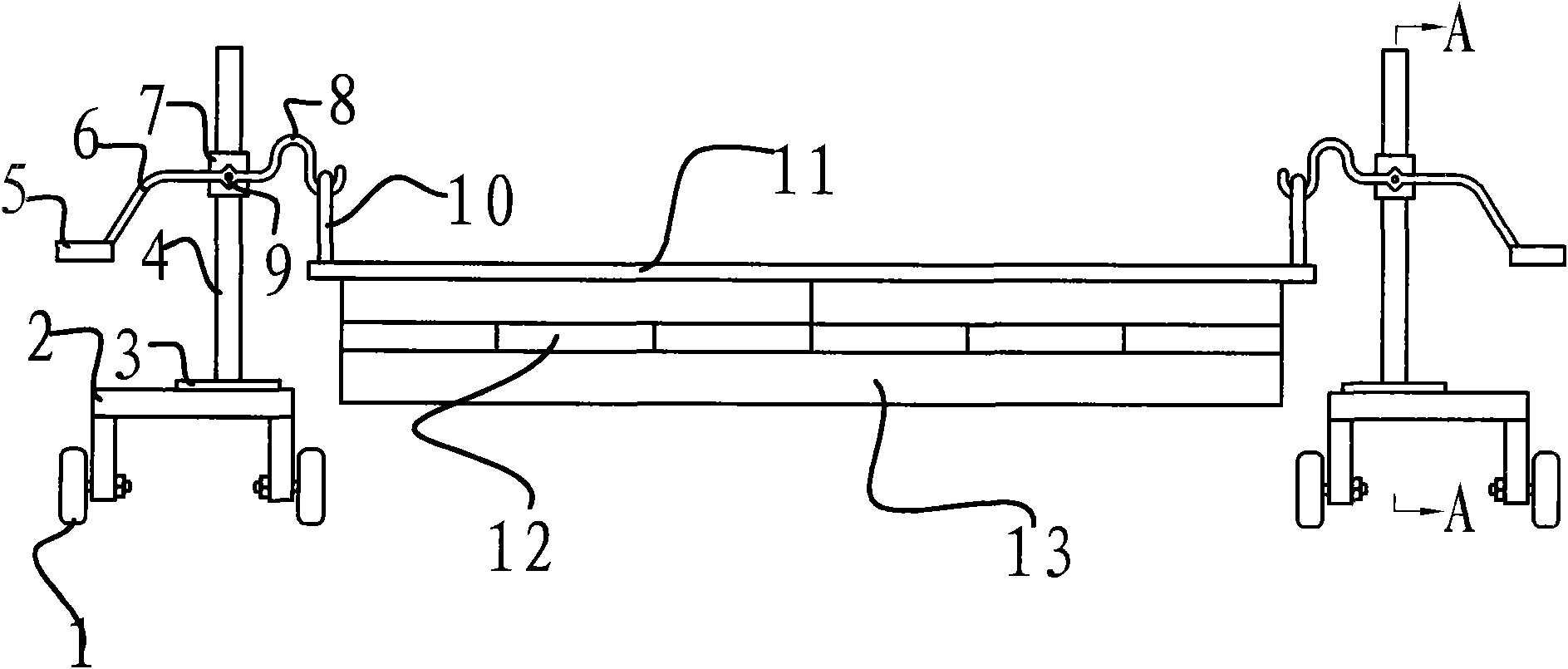

[0020] See figure 1 , the structure of the sidewalk floor tile laying mold is mainly composed of a frame body and a lifting structure. The frame body is composed of an upper frame 11 and a lower brick mold 13, which are connected together, and the lifting structure is connected on the frame 11.

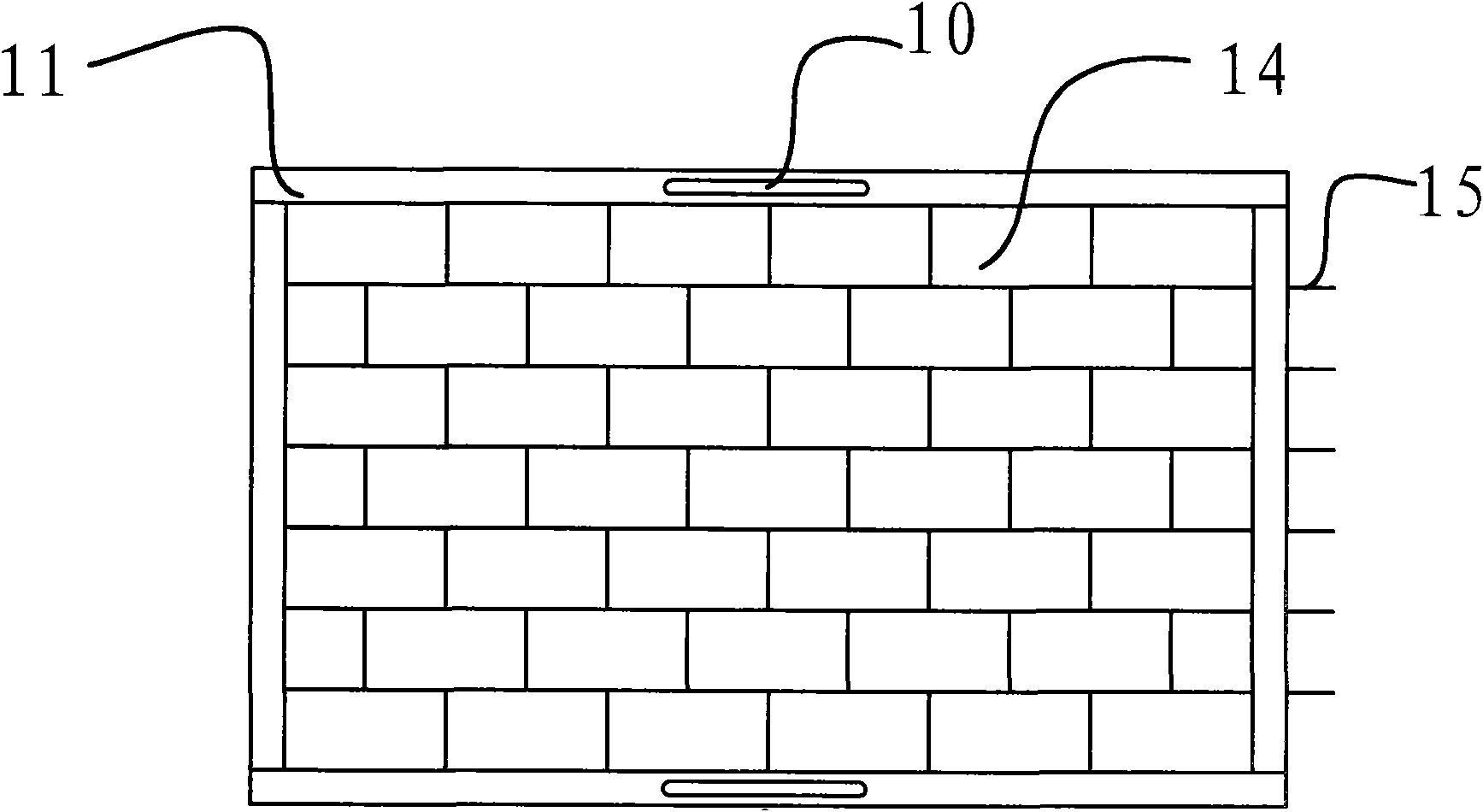

[0021] combine figure 1 , figure 2 , image 3 The brick mold 13 is formed by connecting together some side plates 15, and forms some cavities 14 for placing floor tiles 12 during construction in the brick mold 13, these cavities 14 in the figure are rectangular, figure 2 The cavities 14 are arranged neatly side by side, image 3 The cavities 14 are arranged in a staggered order. The cavity 14 can also be square or polygonal, or various shapes are arranged in a staggered manner, which needs to be prefabricated according to the shape and arrangement requirements of the floor tiles to be laid. See image 3 , if the floor tiles are arranged in a staggered manner, a part of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com