Microscale pulse electrolysis jet processing system and processing method thereof

A technology of pulse electrolysis and processing system, which is applied in the direction of electrochemical processing equipment, processing working medium supply, metal processing equipment, etc. It can solve the problems of affecting stability, increasing technical cost, glass nozzle is easy to break, etc., and achieves electrical conductivity. Good, eliminate pulsation phenomenon, improve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

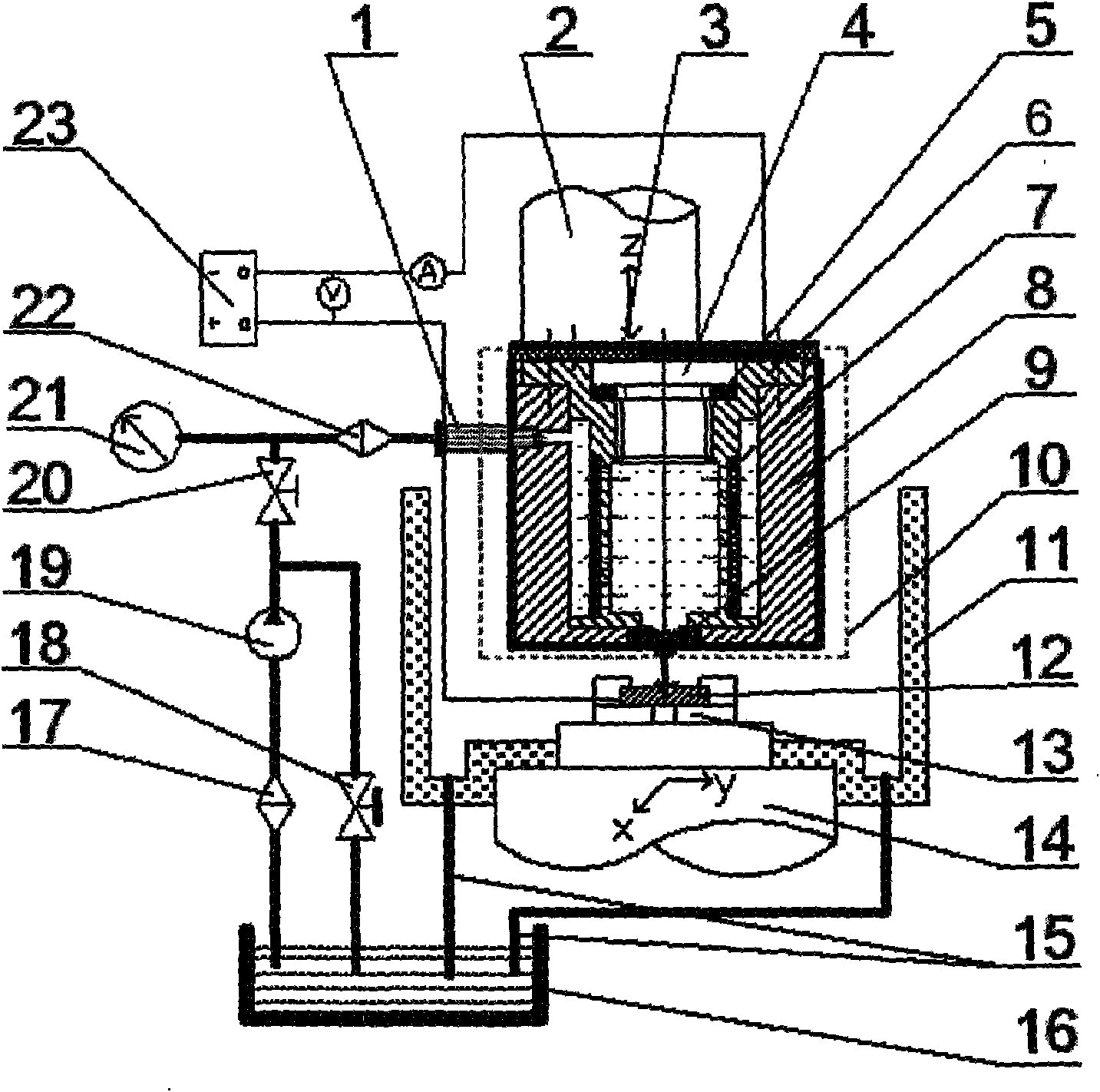

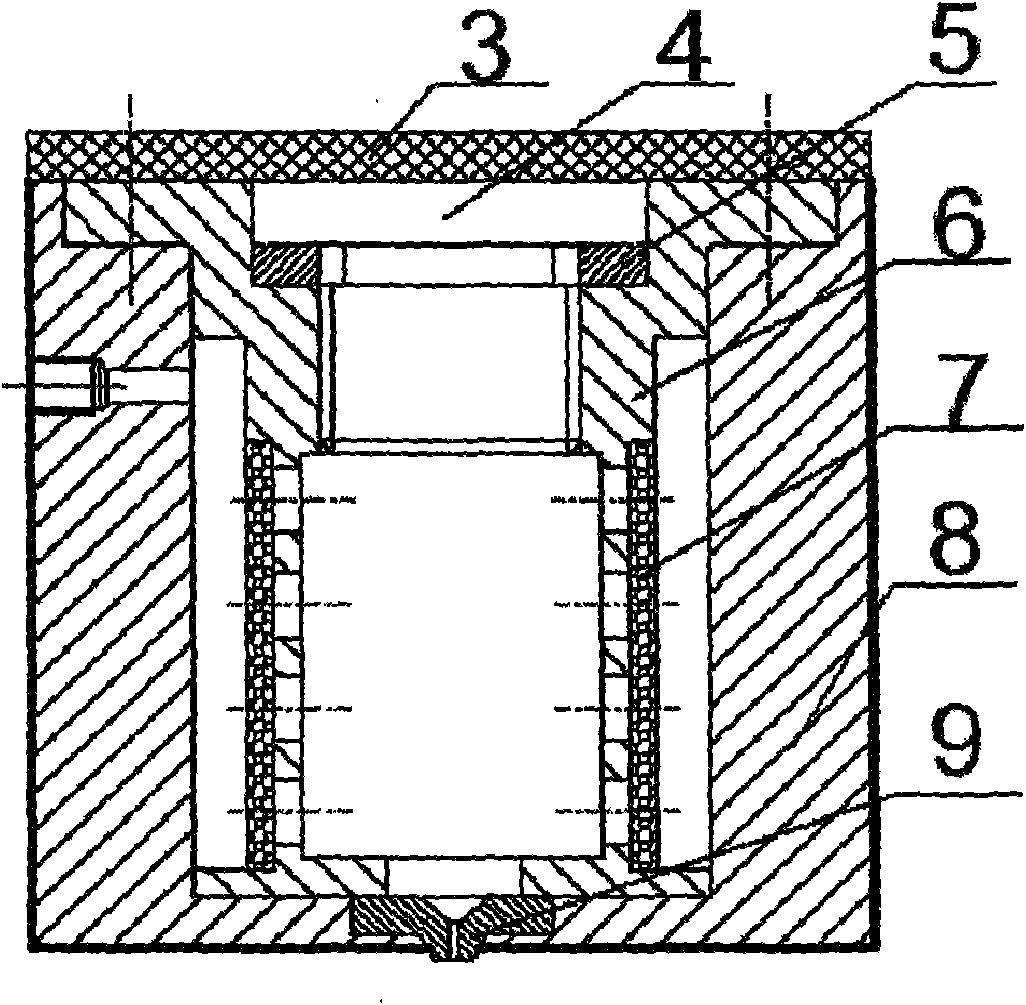

[0010] The device for implementing the micro-scale electrolysis jet processing technology of the present invention includes a high-voltage pulse power supply, an electrolysis jet injection device, an electrolyte circulation and filtration system, a workpiece installation and fixation system, and a workbench motion control system.

[0011] The electrolyte circulating filtration system in the processing system includes a primary filter 17, a secondary filter 22, an overflow pressure regulating valve 18, a hydraulic pump 19, a ball valve 20, a liquid inlet connector 1, a working box 11, and a liquid return Tube 15 and electrolyte tank 16. During processing, the electrolyte passes through the primary filter 17, overflow pressure regulating valve 18, ball valve 20, and secondary filter 21 under the action of the hydraulic pump 19, enters the electrolytic jet injection device 10 through the liquid inlet connector 23, and then passes through the The nozzle 9 shoots at the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com