Method for measuring pressure water absorption rate of lightweight aggregate concrete

A technology of lightweight aggregate concrete and measurement method, which is applied in the direction of using material absorption and weighing, etc., can solve the problems of concrete thickening, losing fluidity, and drying out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

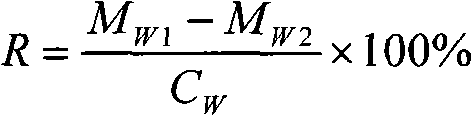

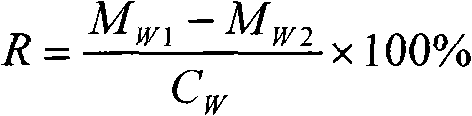

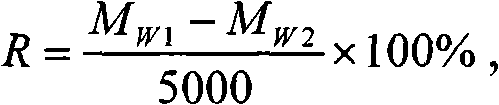

[0015] Usually, light aggregate needs to be pre-soaked or pre-wetted in water before it is formally used for mixing concrete. Since it is soaked or pre-wetted under normal pressure, even if the light aggregate absorbs water saturated or basically stable, the pumping pressure Under the state of pressure, the lightweight aggregate will continue to absorb water until it is saturated with water under pressure. Therefore, how to measure the pressure water absorption rate of lightweight aggregate concrete under pump pressure is the key to achieving smooth pumping.

[0016] In order to solve the phenomenon of clogging and drying of lightweight aggregate concrete during pumping, the method for measuring water absorption of lightweight aggregate concrete under pressure can be used to measure the water absorption of lightweight aggregate concrete under pump pressure, thereby calculating The extra water absorption can be injected into the concrete before pumping the concrete, so as to av...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com