Wave spiral multiphase cosmetic filling device and filling method

A filling device and cosmetic technology, applied in the field of wave spiral multiphase cosmetic filling device, can solve the problems of easy visual fatigue, singleness, waste of resources, etc., achieve good visual effects, reduce use costs, and enrich the market.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

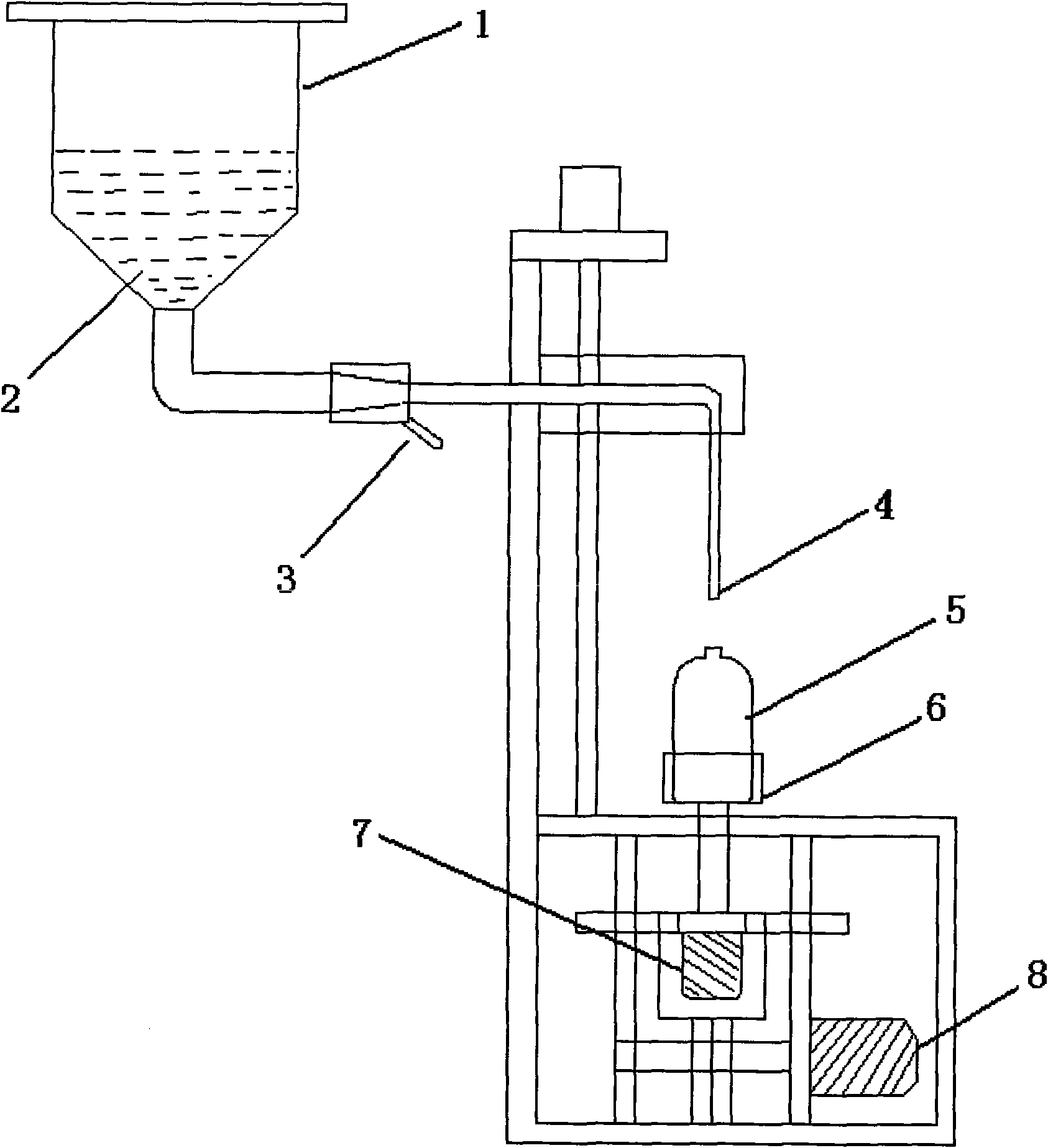

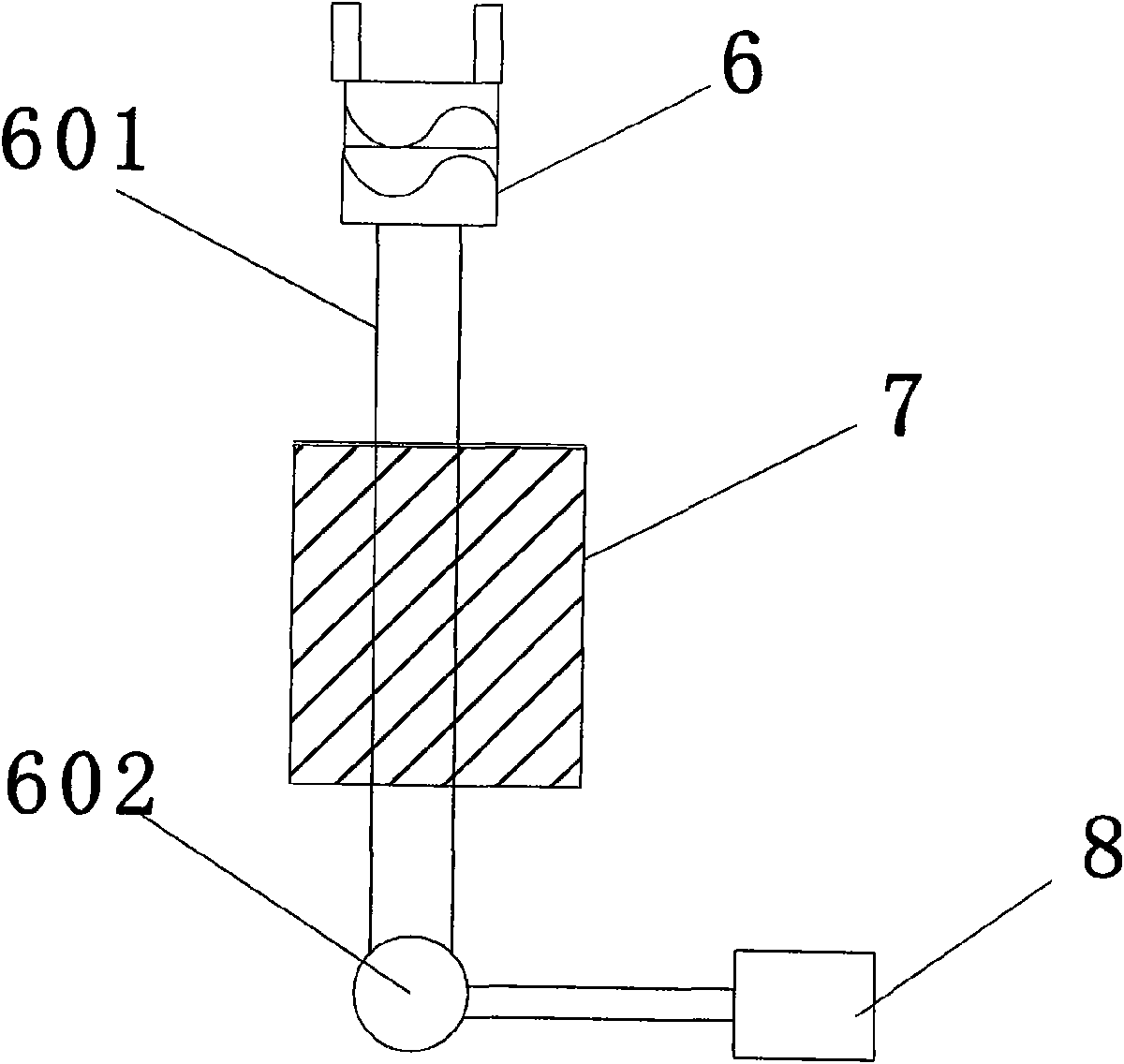

[0026] The core idea of the present invention is to store a variety of finished cosmetics with different colors and properties in multiple different storage tanks, and then extrude these various cosmetics through multiple independent pipelines through air pressure. , and finally fill from the filling nozzle into the transparent filling bottle, wherein in the filling process, first move the multi-head filling nozzle to the bottom of the filling bottle, start filling, and control the lifting rotary base to do plane rotation At the same time, it moves up and down in the vertical direction. In addition, it detects the filling volume of the cosmetics in the filling bottle according to the electronic filling volume sensor, and controls the filling mouth to rise according to the filling volume. When the filling volume reaches the bottle mouth, the filling volume The filling mouth stops the discharge, and moves away from the packaging bottle mouth, returns to the original position, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com