Electrical connection mechanism of plug-in breaker

A circuit breaker and plug-in technology, applied in the direction of switchgear components, etc., can solve the problems of increasing the load of the transmission mechanism, increasing the heating of the circuit breaker, increasing the heating of the circuit breaker, etc., to ensure the conductivity, increase the contact area, and improve the conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

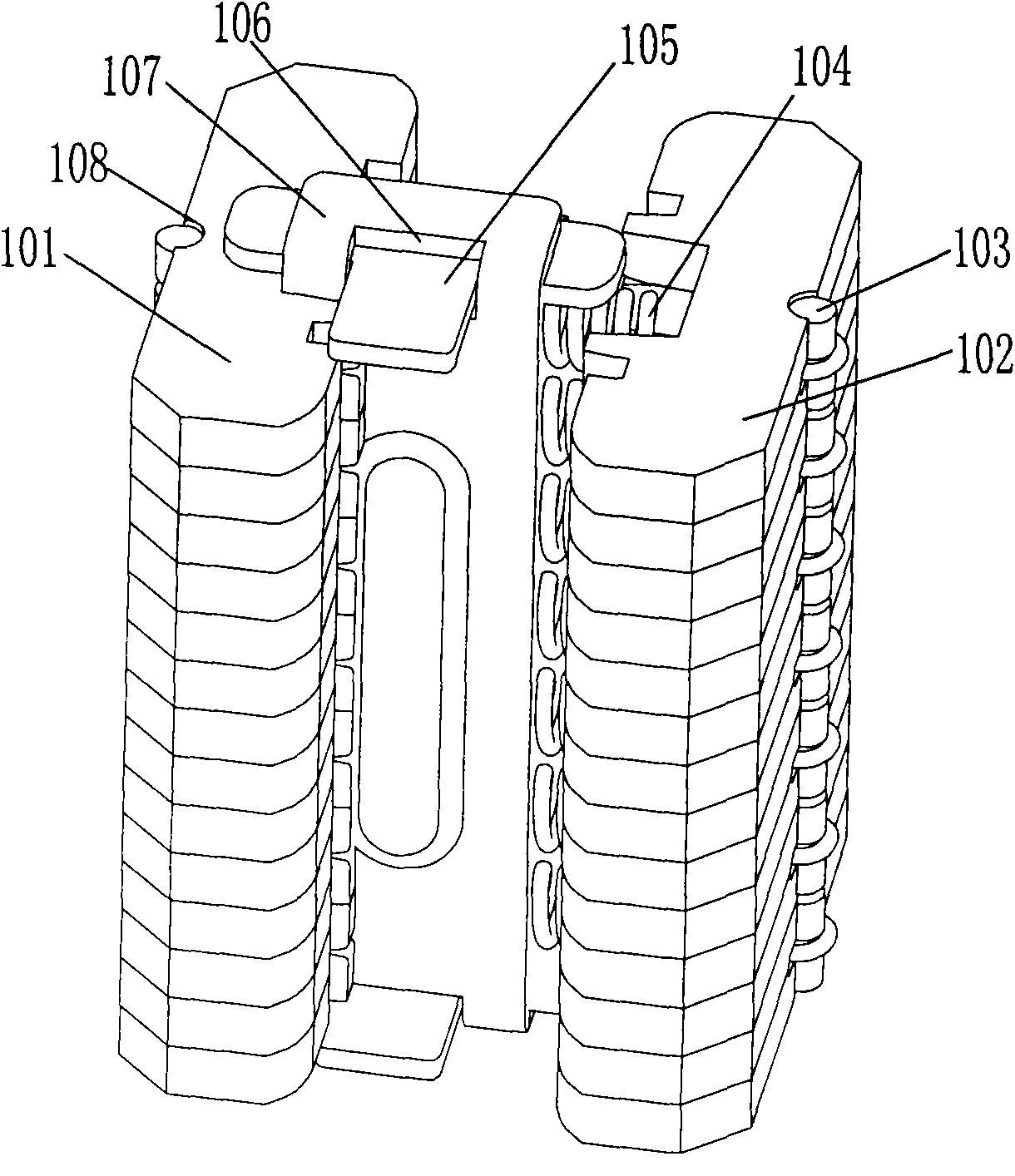

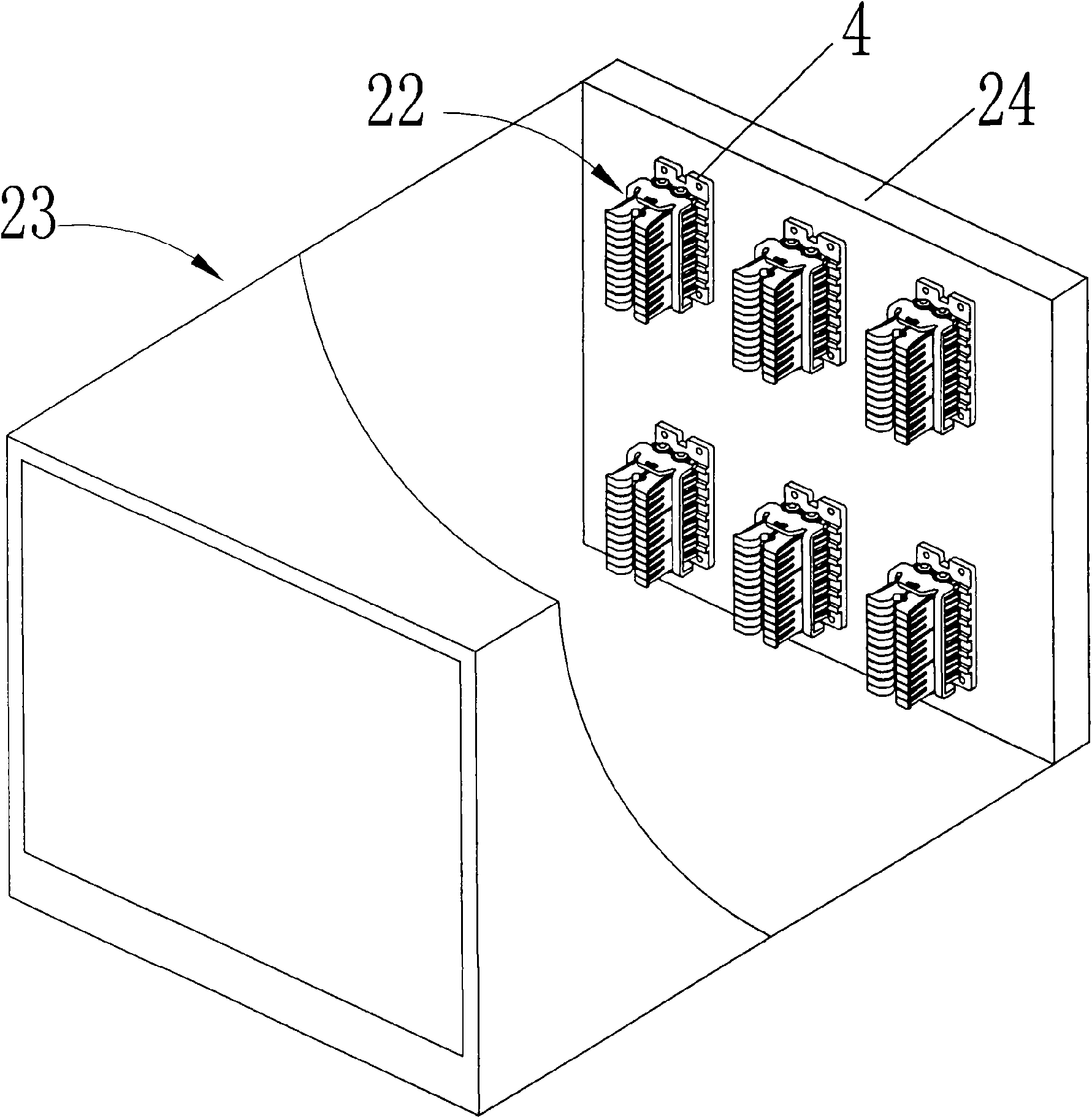

[0030] The present invention is an electrical connection mechanism for a plug-in circuit breaker. It is a functional component structure that realizes the conduction of the main circuit when the busbar 8 of the circuit breaker body is inserted into the drawer seat 23, and otherwise disconnects. Such as image 3 , 4 As shown, the electrical connection mechanism includes: a bus bar 4 fixed on the bottom frame 24 of the drawer seat 23 , two groups of contact pieces 1 and 2 on the left and right, a spring piece 3 , a pin shaft 5 , a central shaft frame 6 and a rectangular frame 7 . in:

[0031] The front end of the busbar 4 extends out a multi-layer horizontal plate 11 toward the direction in which the main body of the circuit breaker is drawn out, and the horizontal plate 11 is provided with two vertical holes 12 symmetrical to the central axis of the busbar ( Figure 5 ), the layer spacing of adjacent horizontal plates is suitable for the thickness of the contact sheet.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com