Guide rail climbing robot motion unit capable of adapting to deviation of guide rail

A robot motion and self-adaptive technology, applied in the direction of hoisting devices, railway car body parts, lifting frames, etc., can solve the problems of reducing the friction force between the guide rail and the vertical guide rail, unable to climb upwards, and potential safety hazards, so as to improve the contact effect, Guarantee the effect of the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

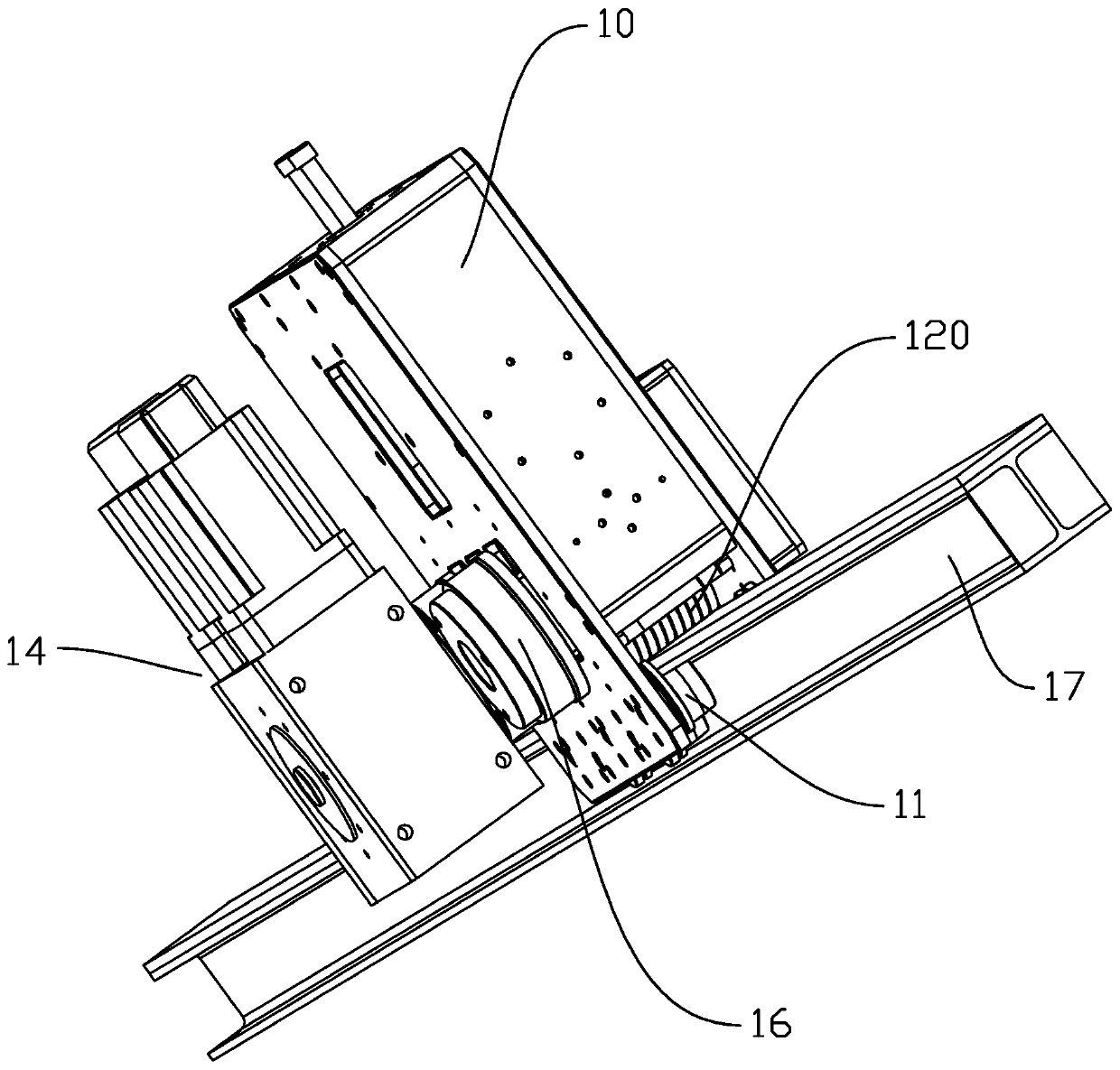

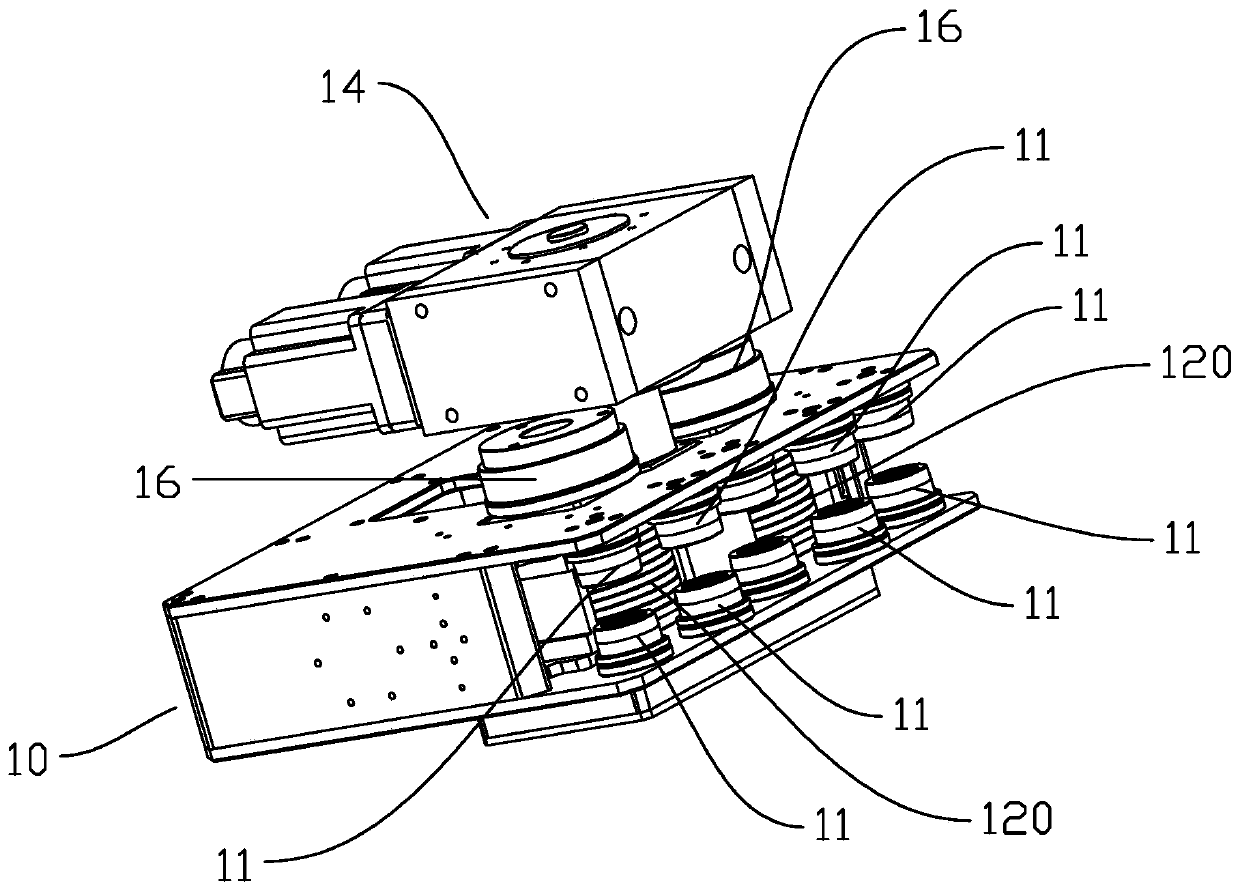

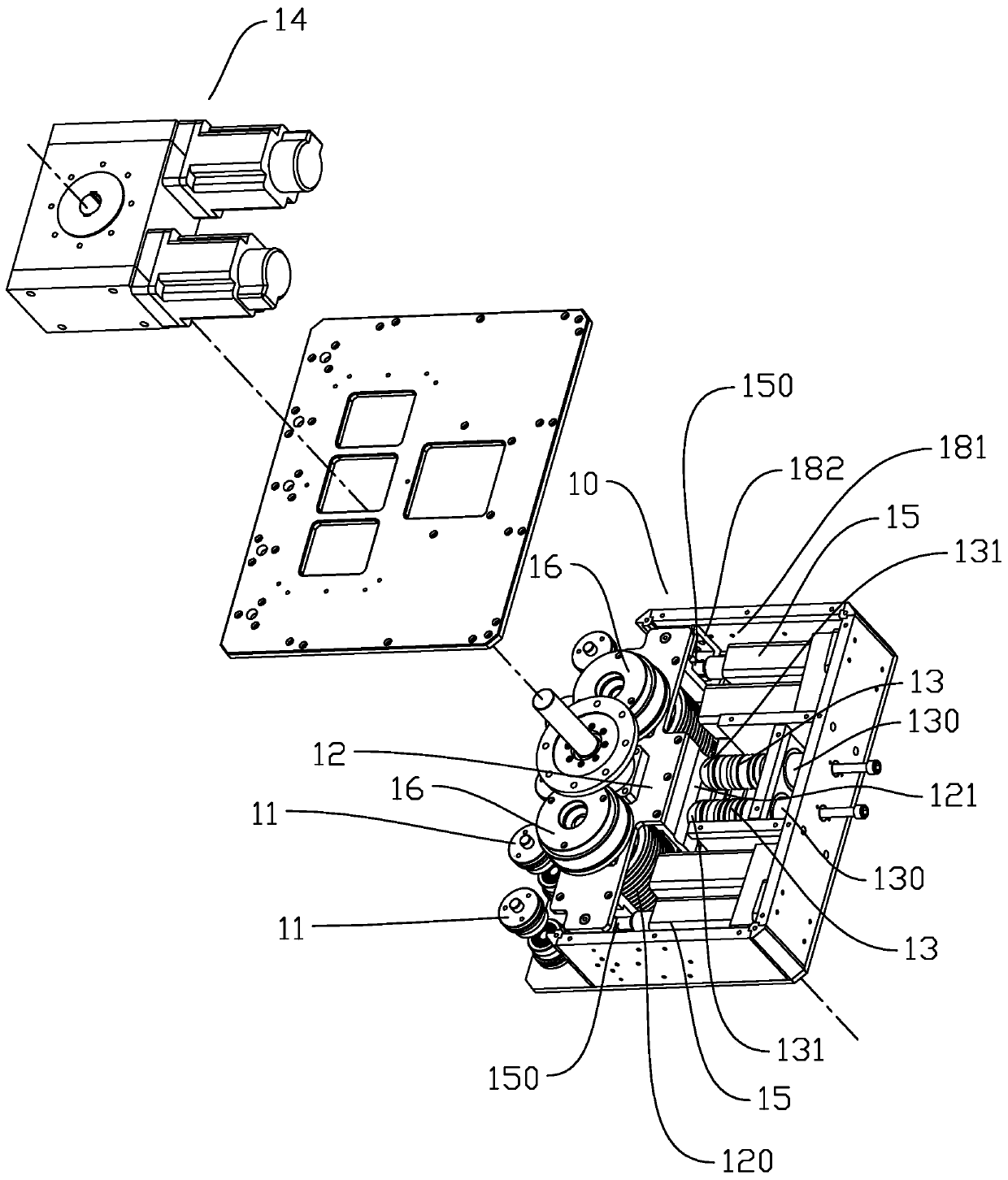

[0032] refer to figure 1 , figure 2 and image 3 , a preferred embodiment of the guide rail climbing robot motion unit of the present invention includes a housing 10, the inside of which is provided with an open chamber; the housing 10 is provided with more than one first guide Wheel 11, here, the quantity of the first guide wheel 11 can be one, two, three or more, in the present embodiment, the quantity of the first guide wheel 11 is multiple, a plurality of first guide wheels The wheel 11 is arranged on the housing 10 and is located at one side of the opening of the cavity; a movable seat 12 that can move relative to the housing 10 is movably installed in the cavity inside the housing 10, so that The movable seat 12 is provided with more than one second guide wheel 120, the second guide wheel 120 is located on one side of the first guide wheel 11, and there is a gap between the first guide wheel 11 and the second guide wheel 120. There is space for the guide rail to pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com