Transmission mechanism for pressure mechanism of upper slide block of forming machine

A technology of slider pressure and transmission mechanism, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of low production efficiency, affecting product quality, complex structure, etc., achieving small energy loss, accurate transmission, Transmission simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

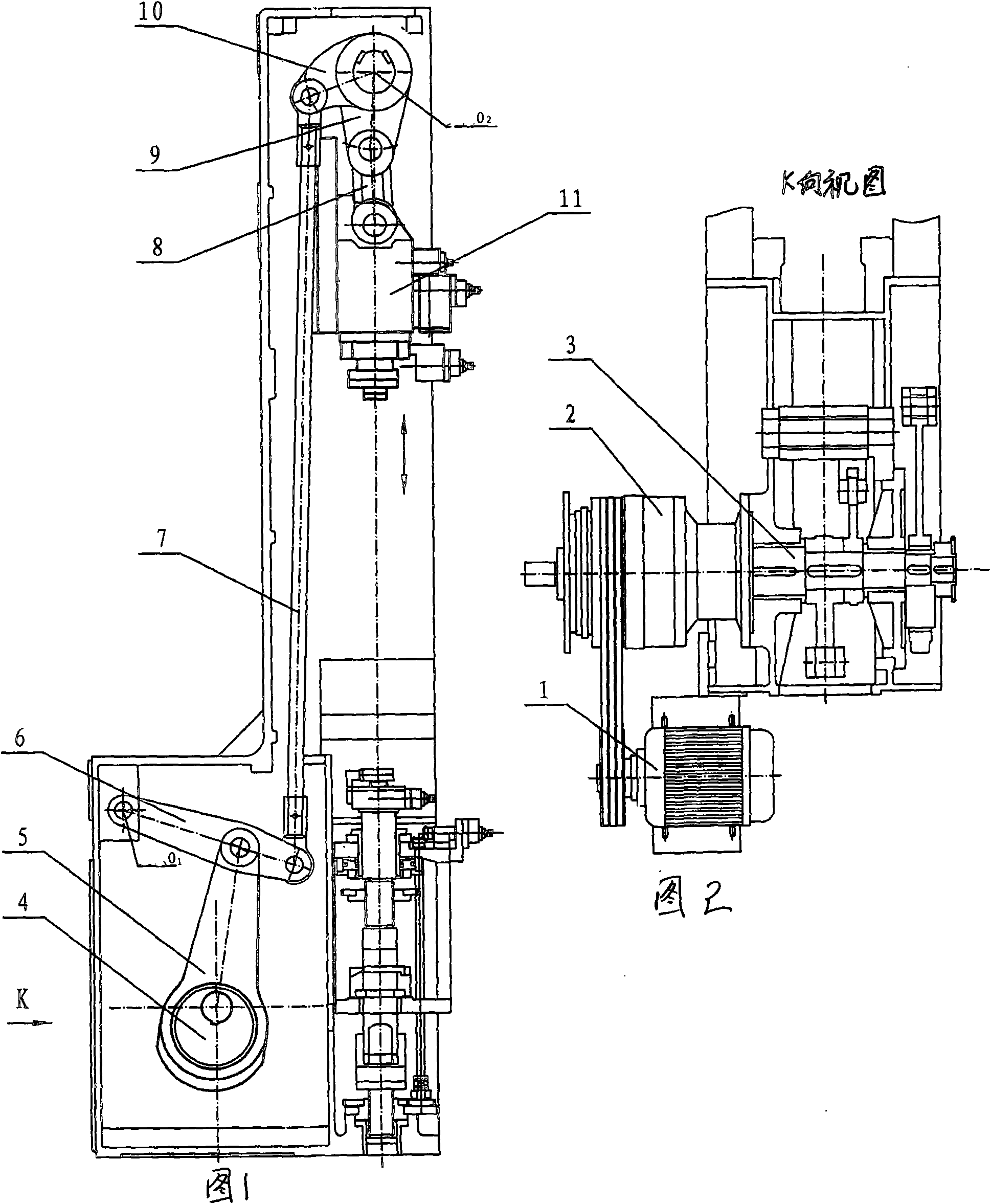

[0009] The present invention is the transmission device of the upper slider pressure mechanism 11 of the molding machine, which is responsible for transmitting the motion requirements and power requirements to the upper slider pressure mechanism 11, and decelerates the high-speed rotational motion of the motor 1 to the molding working speed of the molding machine through the reducer 2. Drive the eccentric mechanism that is made of eccentric wheel 4 and eccentric connecting rod 5 to rotate through transmission shaft 3, and then drive intermediate power transmission toggle lever 6 around the fulcrum by eccentric connecting rod 5. 1 Reciprocating swing up and down, the middle force transmission toggle 6 drives the crank linkage mechanism composed of cranks 9, 10 and connecting rod 8 through the vertical power toggle linkage 7, and finally the crank linkage mechanism drives the upper slider pressure mechanism 11 to reciprocate in a straight line up and down. sports.

[0010] The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com