Blasting electric pole driver

A rod sinker and container technology, which is applied in the field of blasting rod sinkers, can solve problems that affect the production and life of users, cannot effectively ensure safety, consume manpower and material resources, and achieve the effects of simple structure, low operating cost, and short operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

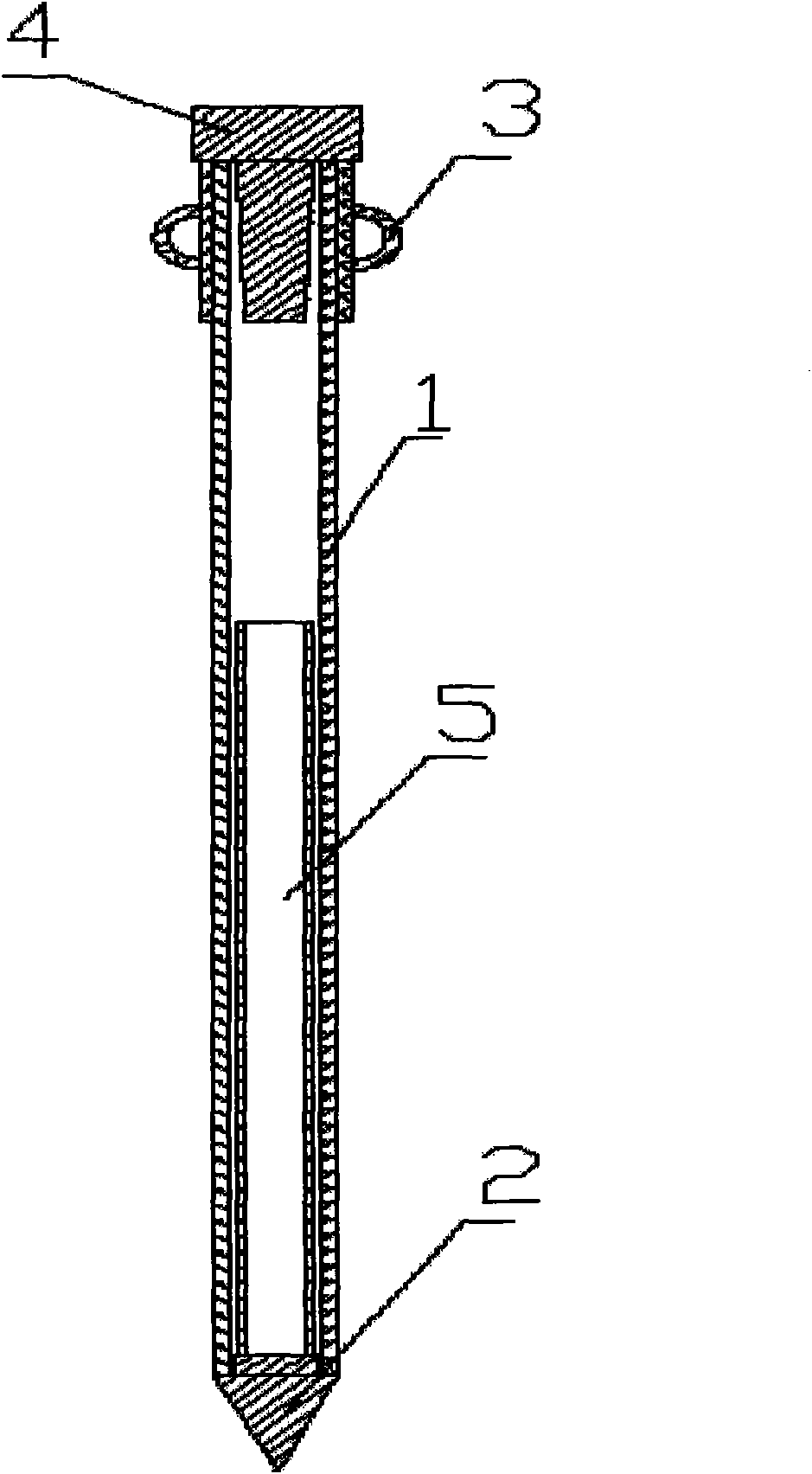

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Such as figure 1 As shown, the surface of the tube 1 of the blasting rod sinker is marked with a length scale, and one end is provided with a movable cone 2, and the tail of the movable cone is a cylinder, which can be inserted into the cavity of the tube. The thickened wall at the other end of the pipe body is provided with lifting lugs 3 , and the port is provided with end caps 4 . A tubular container 5 for placing explosives is arranged in the tube body, and the container is preferably made of frangible material, such as a plastic tube.

[0014] When in use, first ram the pipe body with the movable cone head and end cap installed into the root of the electric pole to be buried deeply. master. Then, the end cover is opened, and the tubular container filled with explosives and detonators is placed in the tube body, and the amount of charge can be determined accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com