Steel structure beam-column slotted hole rotating type high-strength bolt connection ductility joint

A technology of high-strength bolts and oblong holes, applied in the field of steel structure beams and columns, can solve the problems of uncontrollable ductile deformation rotation angle, weakened joint strength, difficult recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

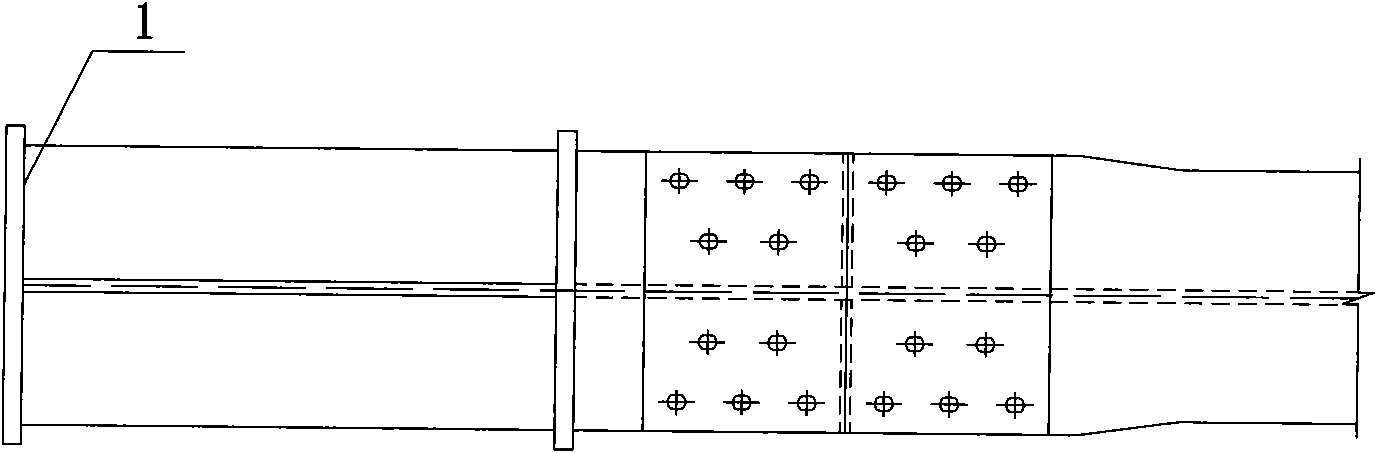

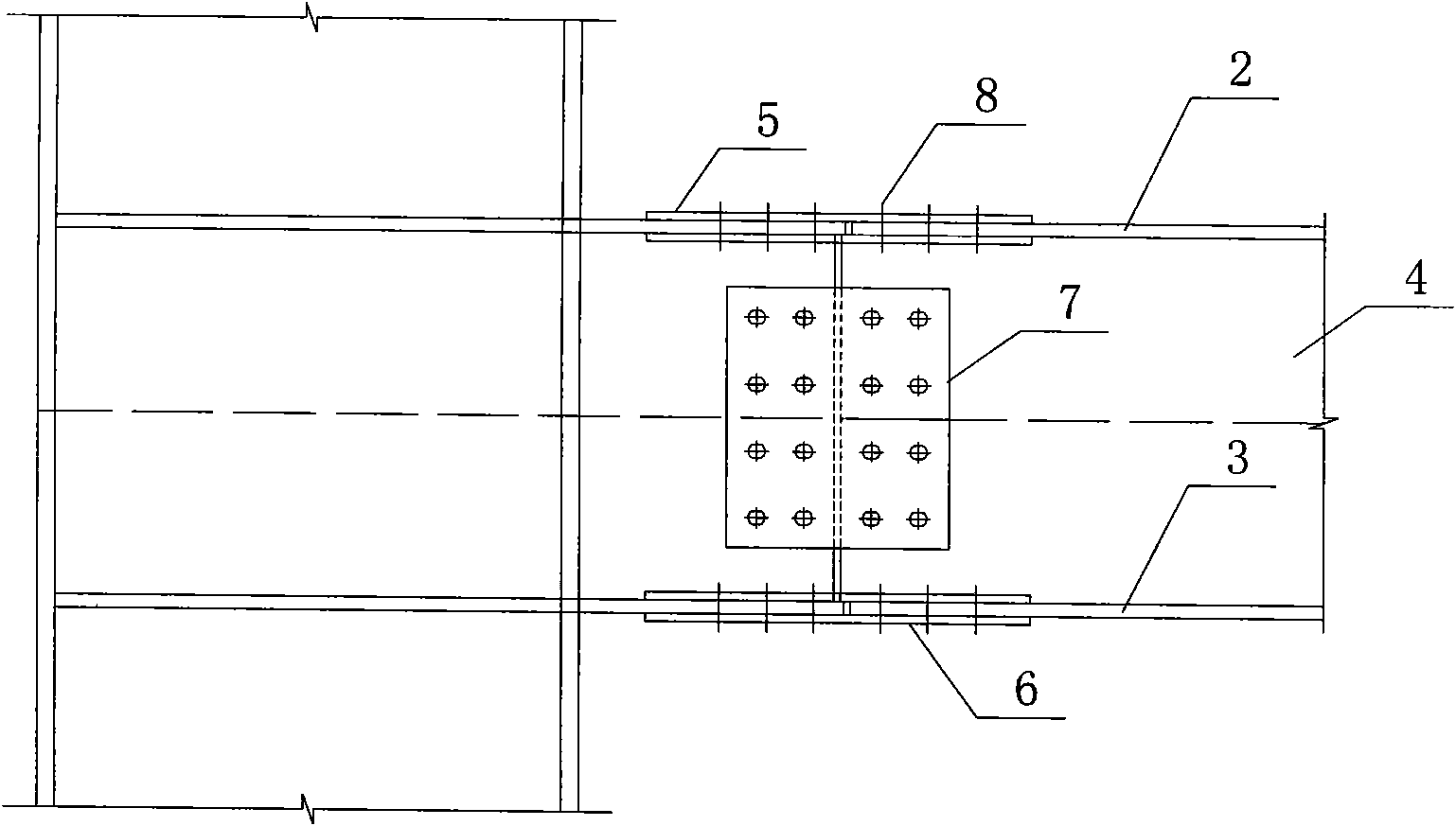

[0016] The present invention mainly consists of a column 1, a beam upper flange plate 2, a beam lower flange plate 3, a beam web 4, a beam upper flange splicing plate 5, a beam lower flange splicing plate 6, a web splicing plate 7, and high-strength bolts 8. Bolts 8 connect the upper and lower flange plates, and the bolt holes of the high-strength bolts 8 are oblong holes along the shearing direction, and the high-strength bolts 8 are located in the middle of the length direction of the oblong holes.

[0017] The width of the beam upper flange plate 2 and the beam lower flange connecting part plate 3 is not less than the width of the upper and lower flanges of the connected beam plus the width weakened by the cross-sectional screw holes.

[0018] The major axis length of the circular hole is d 0 +θh, the minor axis direction is d 0 ,

[0019] d 0 : The diameter of the general screw hole;

[0020] θ: Target rotation angle, ≥3%;

[0021] h: the distance of the hole from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com