Improvement on mechanically composting system

A composting and mechanical structure technology, applied in the field of improved composting devices or systems, can solve the problems of need and energy consumption, and achieve the effect of cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

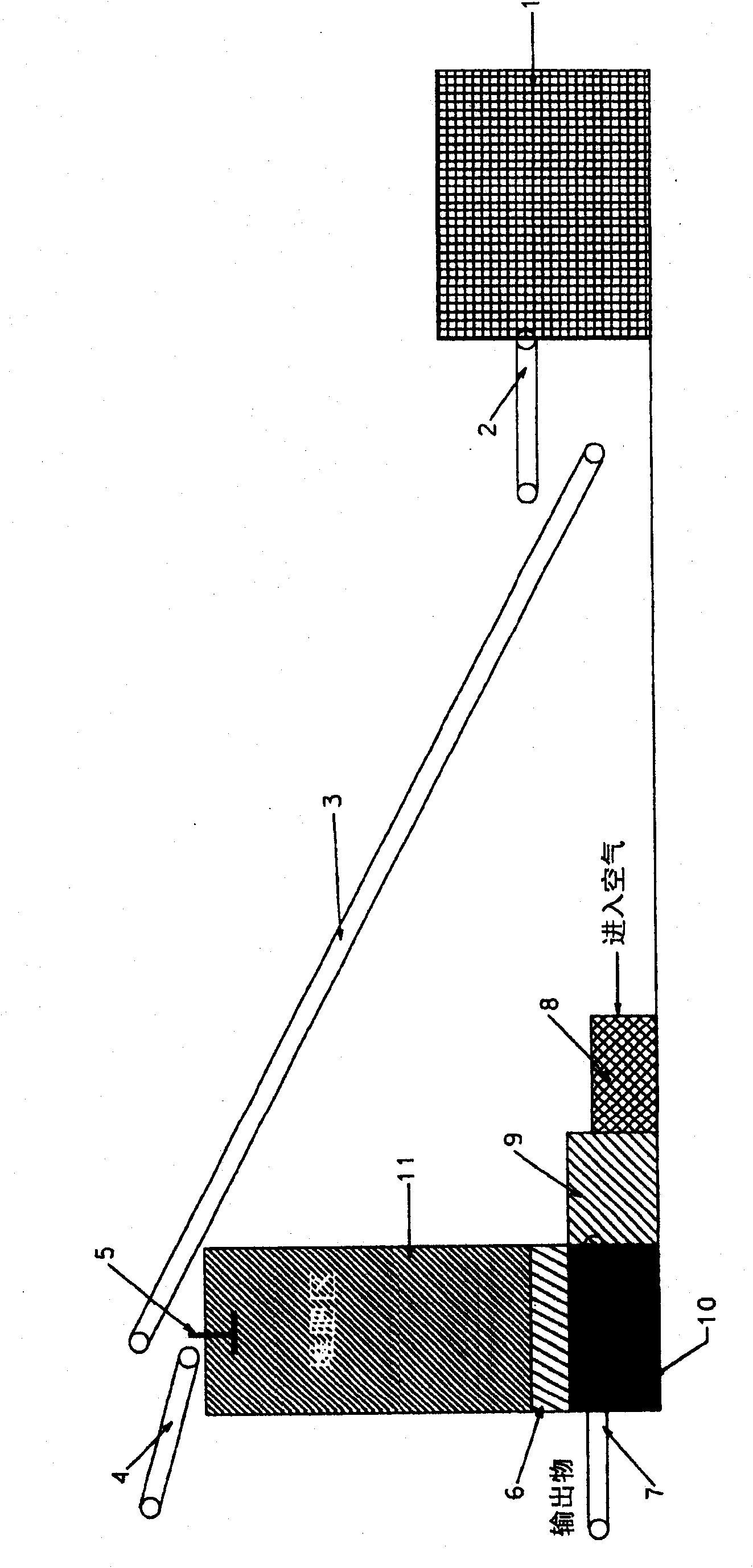

[0040] Example description of the test composting unit

[0041] for the unit ( figure 1 ) are explained below.

[0042] Feeding system: put the material to be treated in the mixer (1) and mix it with any additives. The mixture is then sent by the conveyor (2) to the ramp conveyor (3) and the transverse conveyor (4). The feed is evenly distributed in the tower by the rotating disc (5). Automatic level control allows enough room to empty the feed system. Close and seal the feeder after filling.

[0043] Feed materials: food waste, sewage sludge, animal by-products, some toxic organic waste and some bulking agents (shredded green waste or wood chips) to a maximum mixture density of 0.65T / m 3 . Moisture content ranges from 50%-80%. Additives such as pH adjusting compounds, minerals, nutrients or elements may be required to modify the waste to facilitate processing or to meet end product requirements.

[0044] Extraction system: A material supporting finger bridge roller me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com