Hoisting method of machine set generator stator and special mechanism thereof

A technology of generator stator and hoisting method is applied in the direction of spring mechanism, crane, hoisting device, etc., which can solve the problems of high cost and long hoisting cycle, and achieve the effect of short operation period, simple layout and safe hoisting operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

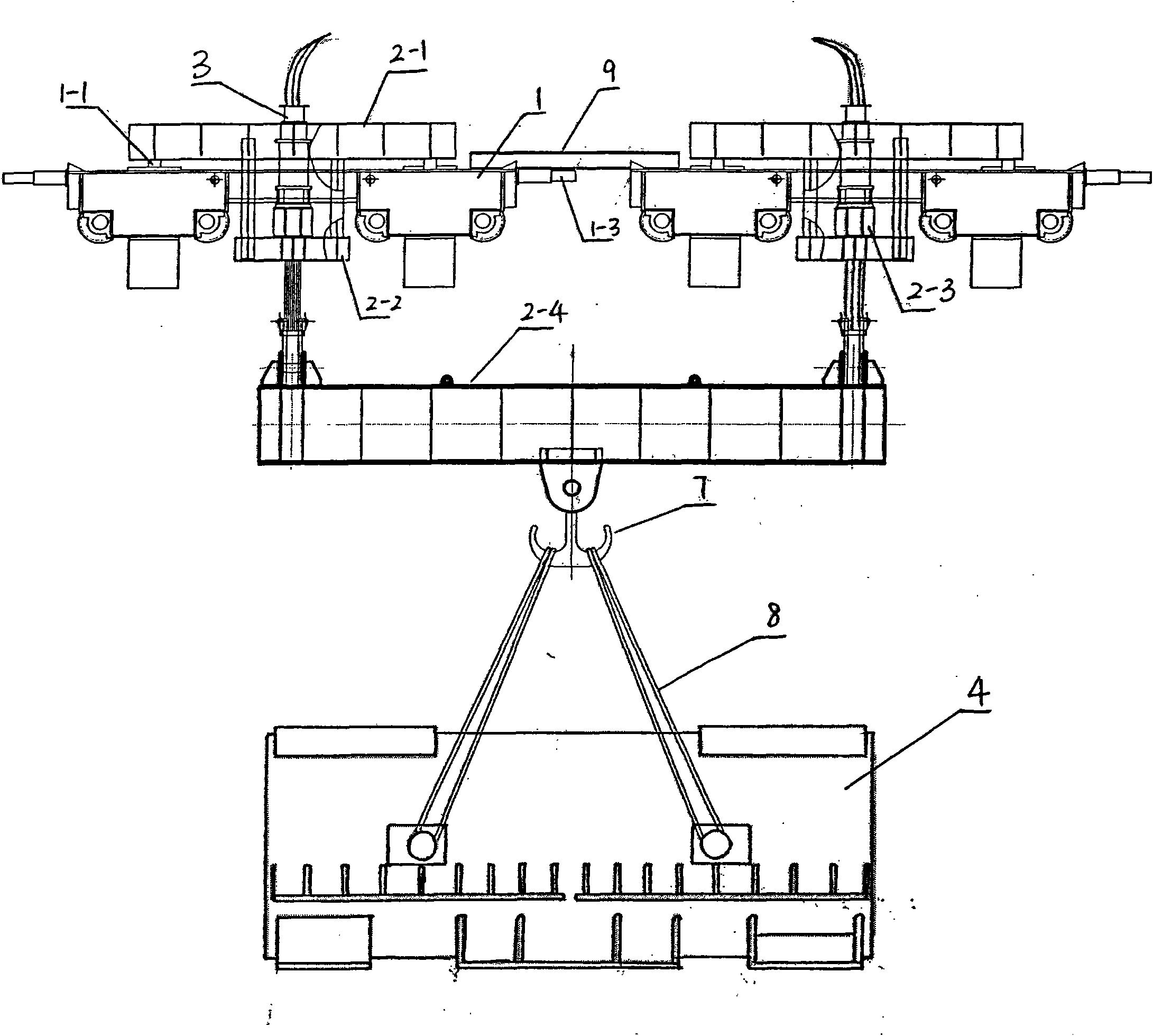

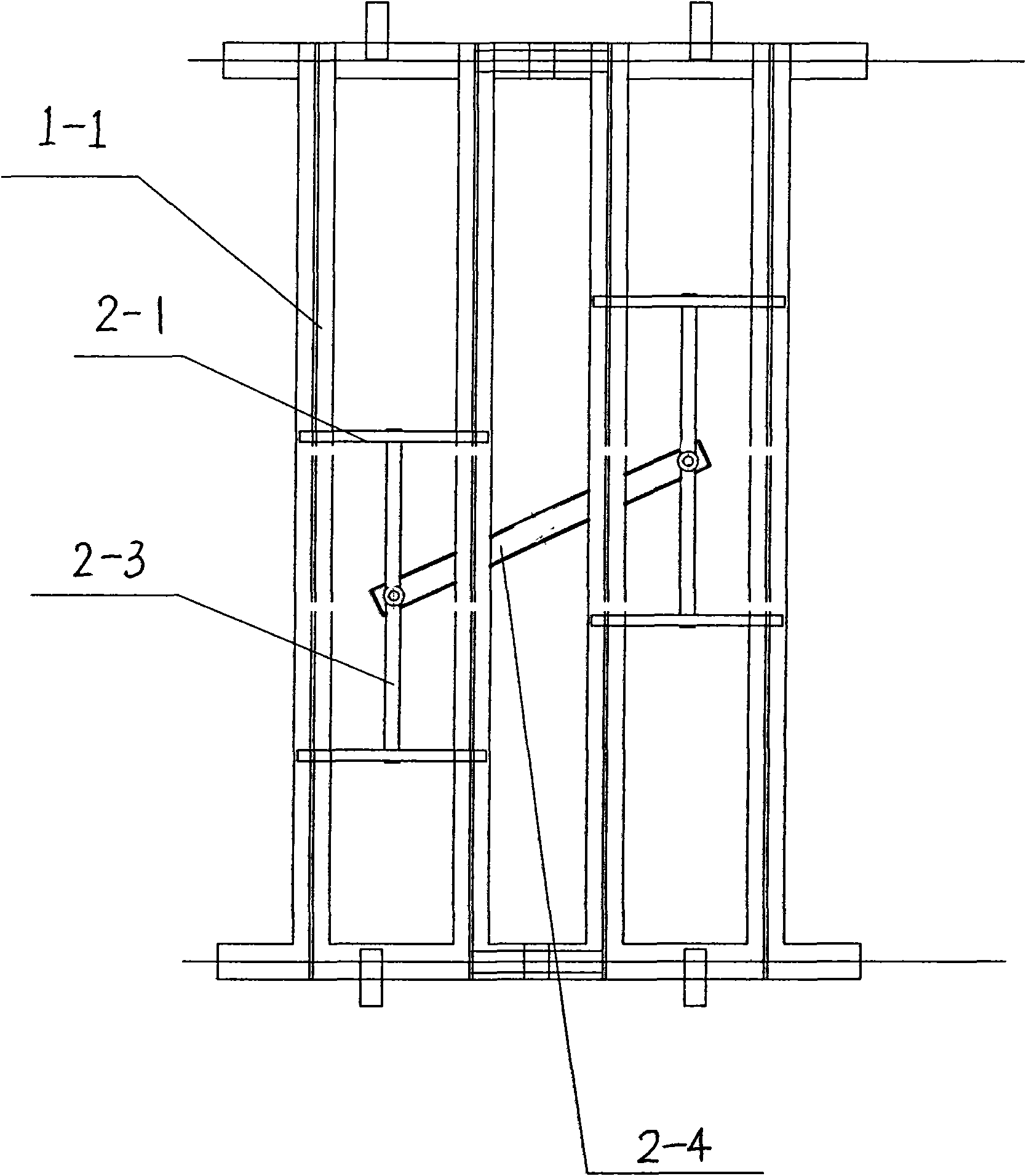

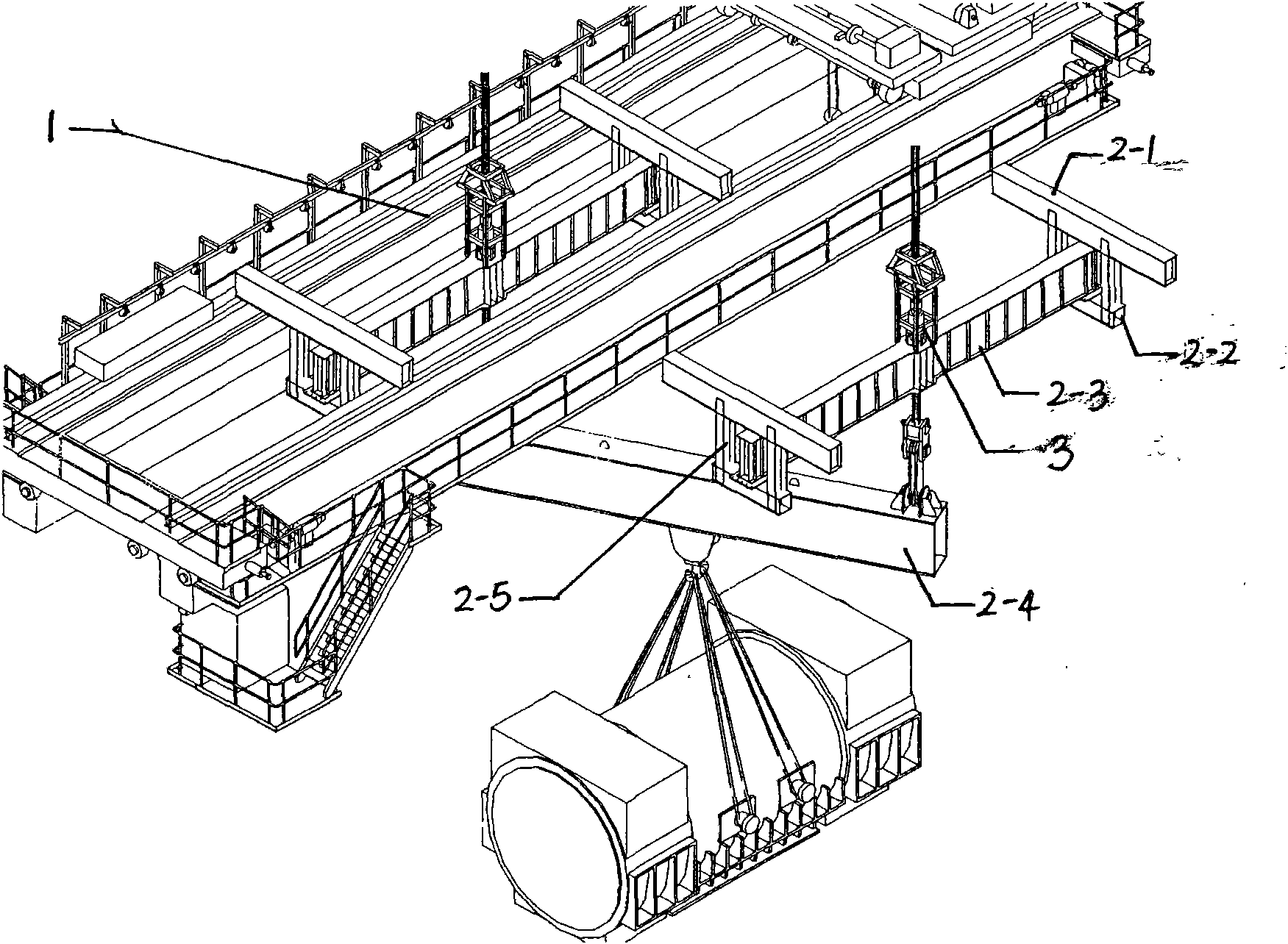

[0036] Such as figure 1 , figure 2 with image 3As shown, the special hoisting mechanism used for hoisting the generator stator of the unit mainly includes adding an auxiliary beam frame structure 2 and a hydraulic lifting device 3 on the basis of two 80-ton driving mechanisms 1 in the main workshop, wherein the driving mechanism 1 includes two The driving track 1-1 and two original trolleys 1-2; the auxiliary beam frame structure 2 includes several upper beams 2-1, several lower beams 2-2, several longitudinal beams 2-3 and at least one pole beam 2-4; Drive the two original trolleys 1-2 to one end of the driving track 1-1 respectively, and use the theodolite to lead the longitudinal centerline of the generator to the girder of the two driving cars. Based on this position, in each driving track 1- Two upper beams 2-1 are placed horizontally on 1, and the two ends of the upper beam 2-1 are placed on the two girders of each driving track 1-1 respectively, and are in movable c...

specific Embodiment 2

[0071] The characteristics of this embodiment are: a power plant uses the special hoisting mechanism and hoisting method for hoisting the stator of the unit generator of the present invention to successfully hoist the stator with an external dimension of 9.32m×3.64m×4m and a weight of 196t; Arrange two 80t cranes with a span of 25.3m; the stator is located on the 12.47m platform of the steam turbine operation floor.

[0072] Table 1 Stator hoisting load list

[0073]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com