Soy milk grinder

A soymilk machine and machine head technology, which is used in milk substitutes, beverage preparation devices, household appliances, etc., can solve the problems of easy to paste pipes, paste bottoms, and insufficient circulation of slurry, achieve good alcoholization effect, and prevent bottom sticking. , full flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

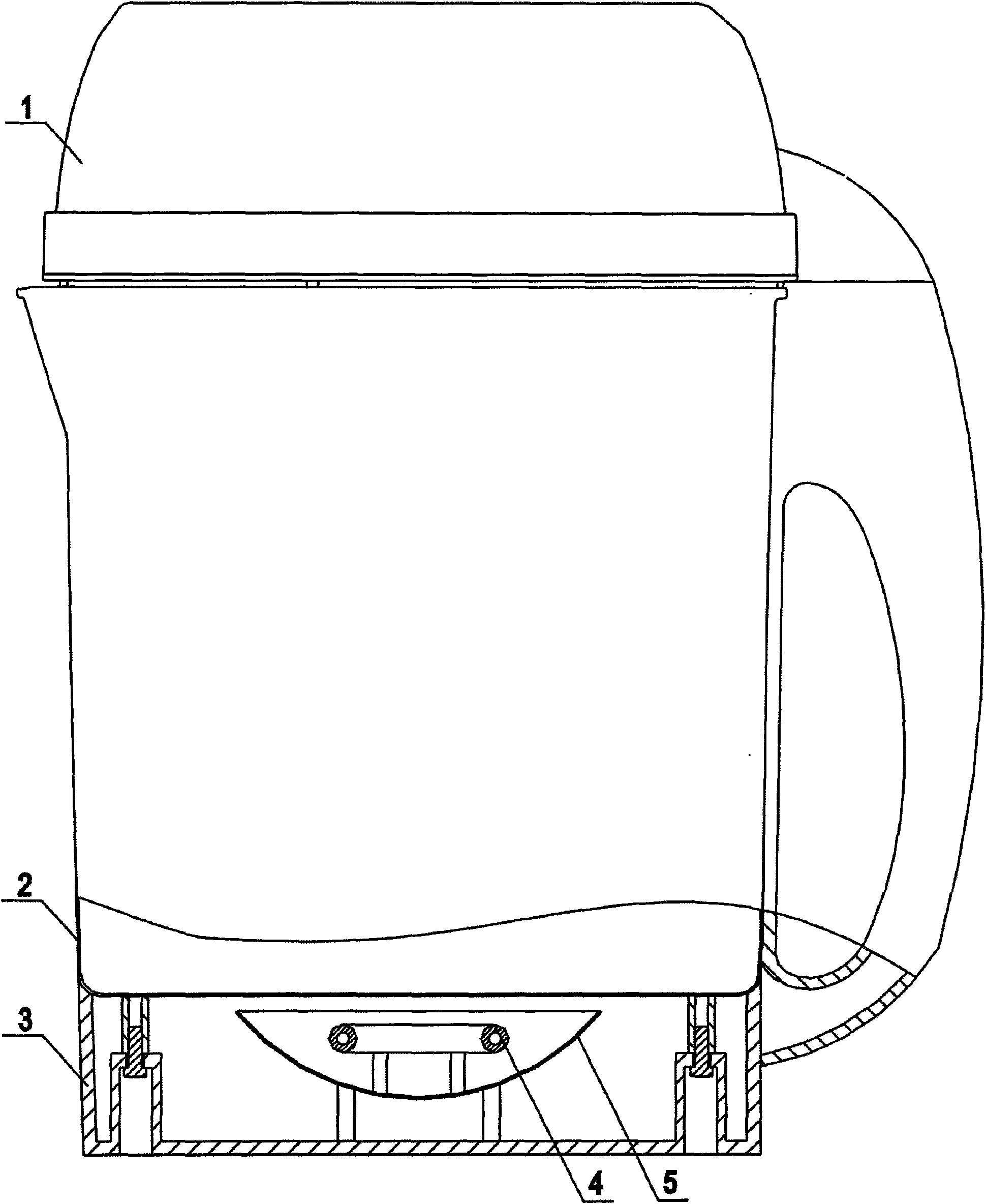

[0021] As the first embodiment of the soybean milk machine of the present invention, as figure 1 As shown, it includes a machine head 1, a cup body 2 and a base 3. The machine head 1 is arranged above the cup body 2, and the base 3 is arranged below the cup body 1. A cavity is formed between the cup body 2 and the base 3, and the cavity There is a heating element inside, the heating element in this embodiment is a halogen tube 4, the halogen tube 4 is fixedly installed on the base 3, a reflector 5 is arranged under the halogen tube 4, the halogen tube 4 is contained in the reflector 5, and the reflector 5. The light and heat emitted by the halogen tube 4 can be evenly focused on a small heating area in the center of the cup bottom, because the halogen tube 4 is not in direct contact with the bottom of the cup, but conducts heat through the air, so the temperature on the heating area is very high Uniformity, the temperature of the slurry above the heating surface rises faster t...

Embodiment 2

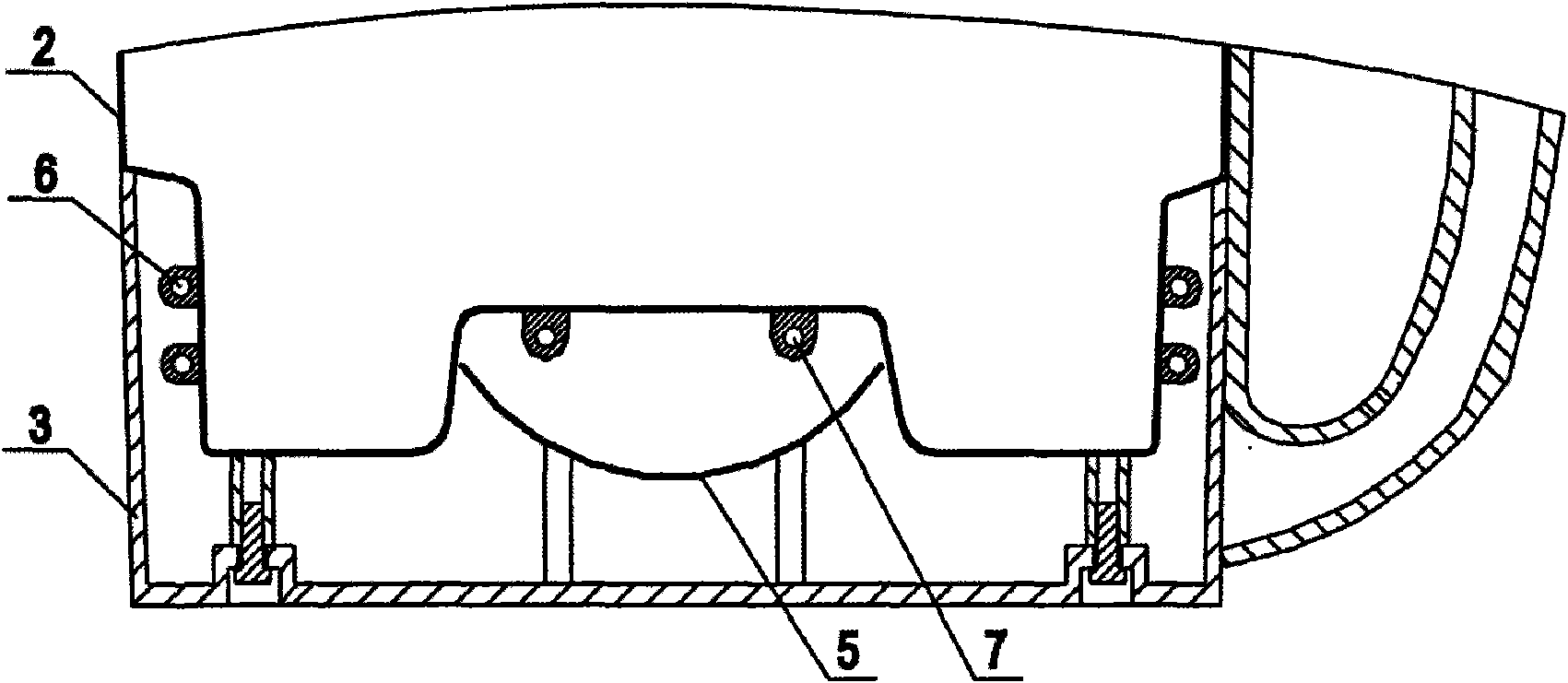

[0024] As the second embodiment of the soybean milk machine of the present invention, as figure 2 As shown, the difference from Example 1 is that the bottom of the cup body is an upwardly convex curved surface structure. This structure can not only increase the temperature difference between the center of the cup bottom and its surroundings, so as to form a more obvious "fountain" effect, but also It has a certain turbulence effect on the slurry and plays a positive role in auxiliary crushing. When adding materials, the materials can be automatically or manually gathered to the bottom of the cup body. Since the bottom is a non-heat source and the temperature is low, it will not The resulting material sticks to the bottom during the rapid preheating stage, and other structures and beneficial effects are consistent with Embodiment 1, and will not be repeated here.

Embodiment 3

[0026] As embodiment three of the soybean milk maker of the present invention, as image 3 As shown, the difference from Embodiment 2 is that the heating element at the bottom of the cup is a carbon fiber tube 7, and the carbon fiber tube 7 is fixed on the bottom of the cup body by welding or brazing; An example is the electric heating tube 6 installed on the side of the cup body, the carbon fiber tube 7 and the electric heating tube 6 can be operated at the same time during the preheating stage or when rapid heating is required, so as to achieve the purpose of fast hot water; when boiling, the carbon fiber tube 7 can be operated alone , in order to form a "fountain" effect, other structures and beneficial effects are consistent with the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com