Optical-fiber temperature measuring probe and optical cable cooling method in high-temperature environment

A technology for optical fiber temperature measurement and high temperature environment, which is applied in radiation pyrometry, optical radiation measurement, measuring devices, etc., can solve the problems of high cost, burning and scrapping of optical cable bundles, etc. high rate effect

Inactive Publication Date: 2010-08-18

SHANXI TAIGANG STAINLESS STEEL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the ambient temperature is higher than 450°C and the furnace is continuously working, if the compressor fails and the cold air cannot be supplied for a short time, the optical fiber temperature measuring probe and the optical cable bundle will be burned within an hour without any protective measures. Lost and scrapped

At present, the cold preservation method adopted abroad is to lay a plurality of thin tubes passing through the optical fiber temperature measuring probe and the optical cable bundle in the cuboid square tube, and lay two cooling air ducts along the thin tubes, and apply refractory materials to the outside of the cuboid square tube for heat insulation. The cost of the method is high, and many materials used are still difficult to solve domestically

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

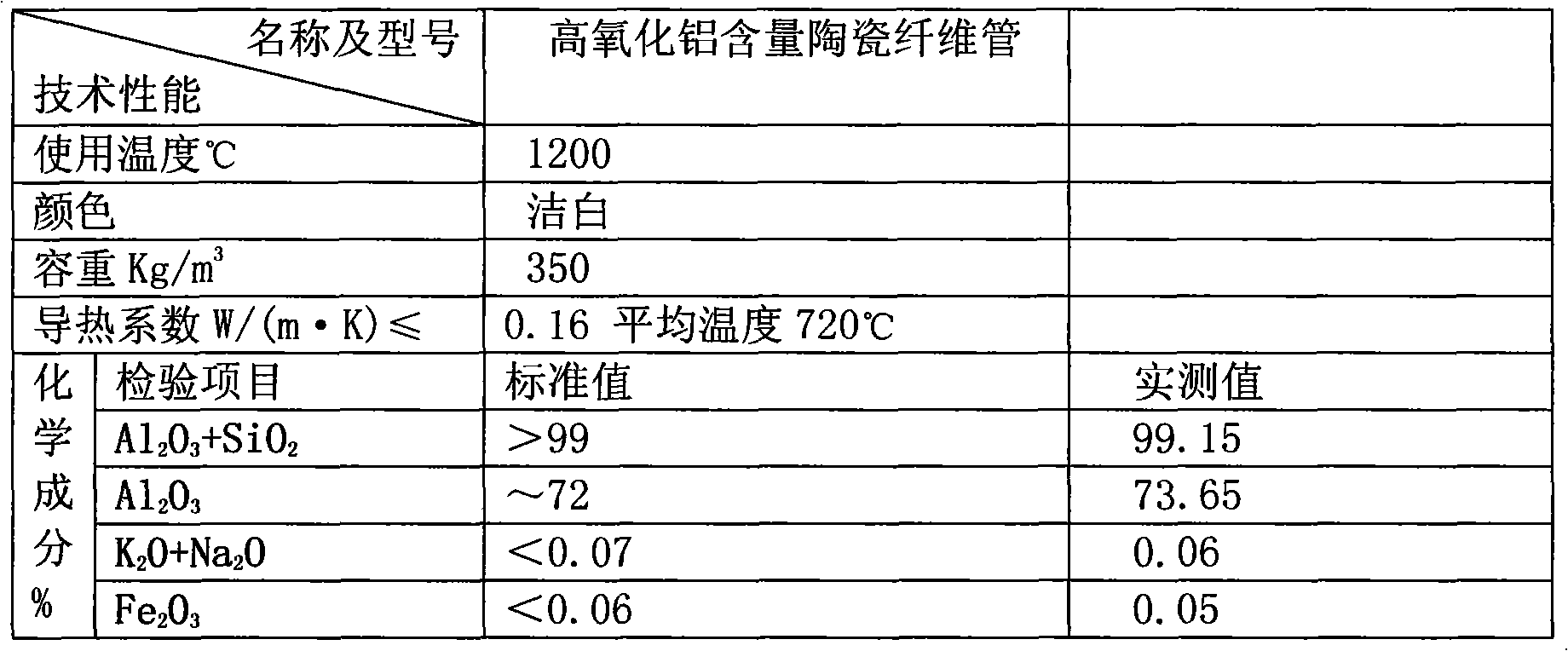

The invention relates to an optical-fiber temperature measuring probe and an optical cable cooling method in a high-temperature environment, which are both suitable for an optical-fiber continuous temperature measuring system of an industrial furnace and aim to achieve low cost and good heat insulating and radiating effects. A polycrystalline ceramic fiber pipe with high aluminum oxide content issleeved outside a stainless steel soft sleeve pipe which is provided with an optical cable seam as a heat insulating material, a polycrystalline high-purity aluminum silicate ceramic fiber blanket isbound outside a polycrystalline high aluminum oxide ceramic fiber sleeve pipe and used as a heat insulating material, aluminum silicate glass fiber cloth is wound outside the high-purity ceramic fiber blanket in a spiral mode, the optical-fiber probe is arranged on the upper part or the middle part or the lower part of a rear upright post of a pushing upright post, a wind cooling steel sleeve is additionally arranged outside the optical-fiber probe, sapphire quartz glass and cooling air blowing pipe are arranged in the steel sleeve, the quartz glass is blocked in front of the optical-fiber probe, cooling air is blown out from the front end of the steel sleeve, a stainless steel outer cylinder is additionally arranged outside the steel sleeve, and ceramic fiber castable refractory is filled in a gap between the stainless steel outer cylinder and the steel sleeve and used as a cooling wall.

Description

technical field The invention relates to a heat insulation and cold preservation method for an optical fiber thermometer in a high temperature environment, which is mainly used for cooling protection of a continuous temperature measurement system of an industrial furnace. Background technique Existing optical fiber temperature measuring probes and optical cables are usually protected by stainless steel soft sleeves. If they are used in a high temperature environment for a long time, they need to be blown into compressed air to cool them to ensure their service life. However, if the ambient temperature is higher than 450°C and the furnace is continuously working, if the compressor fails and the cold air cannot be supplied for a short time, the optical fiber temperature measuring probe and the optical cable bundle will be burned within an hour without any protective measures. Lost and scrapped. At present, the cold preservation method adopted abroad is to lay a plurality of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01J5/02C04B35/10C04B35/18G02B6/44C04B35/66

Inventor 孙原生卢海宁

Owner SHANXI TAIGANG STAINLESS STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com